Forming process of diamond roller for dressing grinding wheel and graphite substrate

A technology for diamond rollers and dressing grinding wheels, which is applied to the forming process of diamond rollers and the field of graphite substrates, can solve the problems of affecting the wear resistance of diamond rollers, labor, and falling off of steel stones, so as to facilitate the secondary pressing and sintering processes, Ease of placement, wear resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

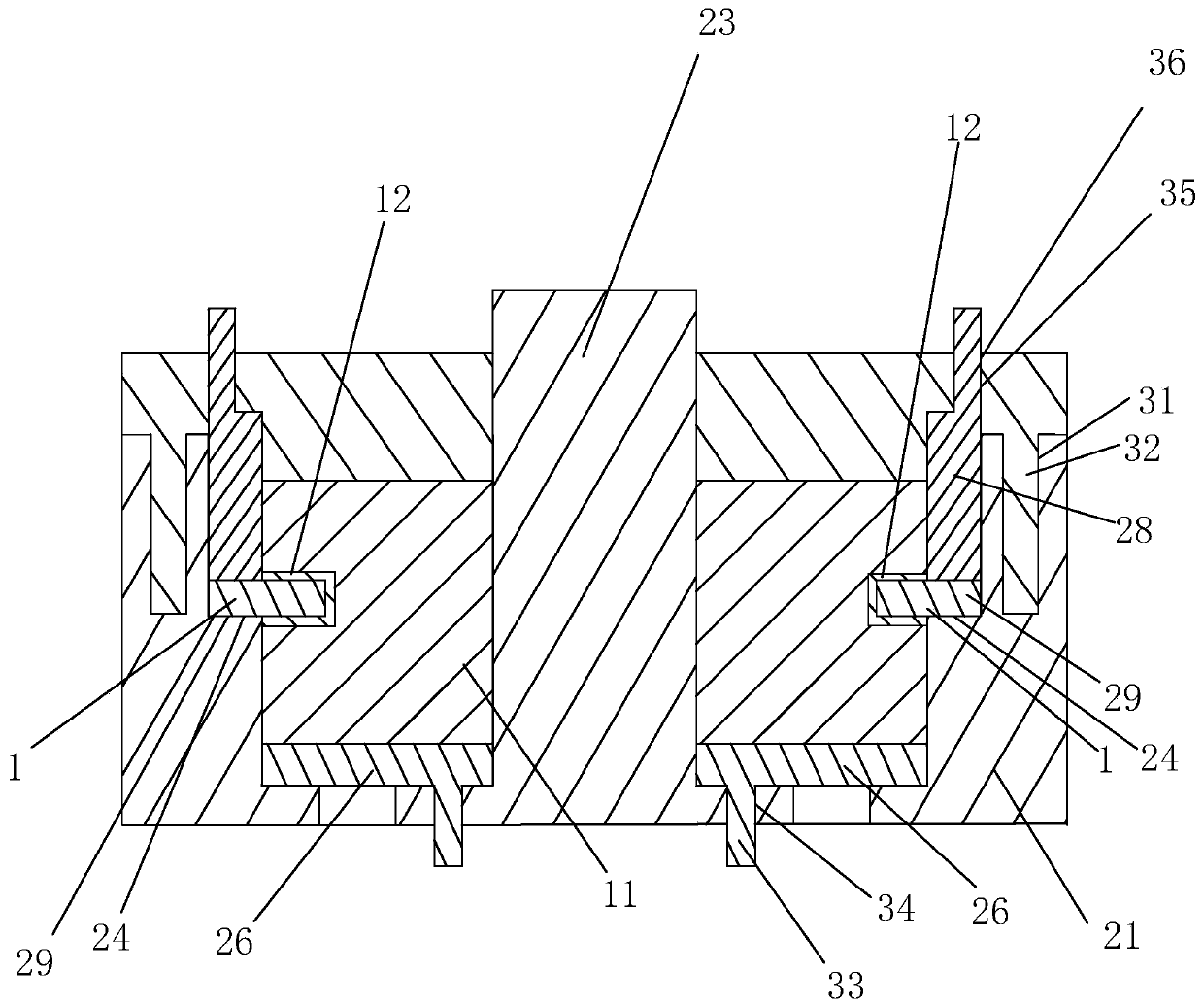

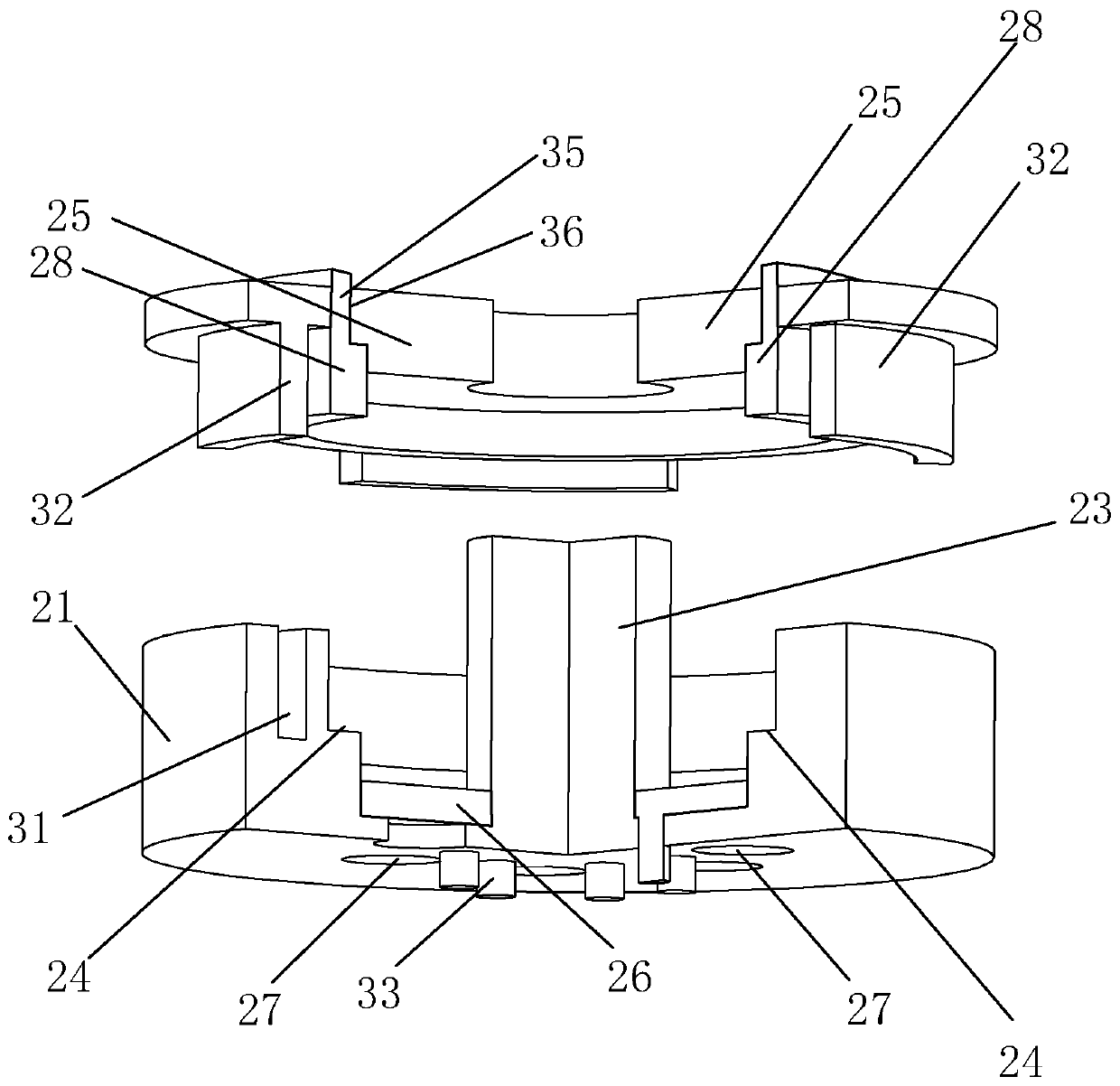

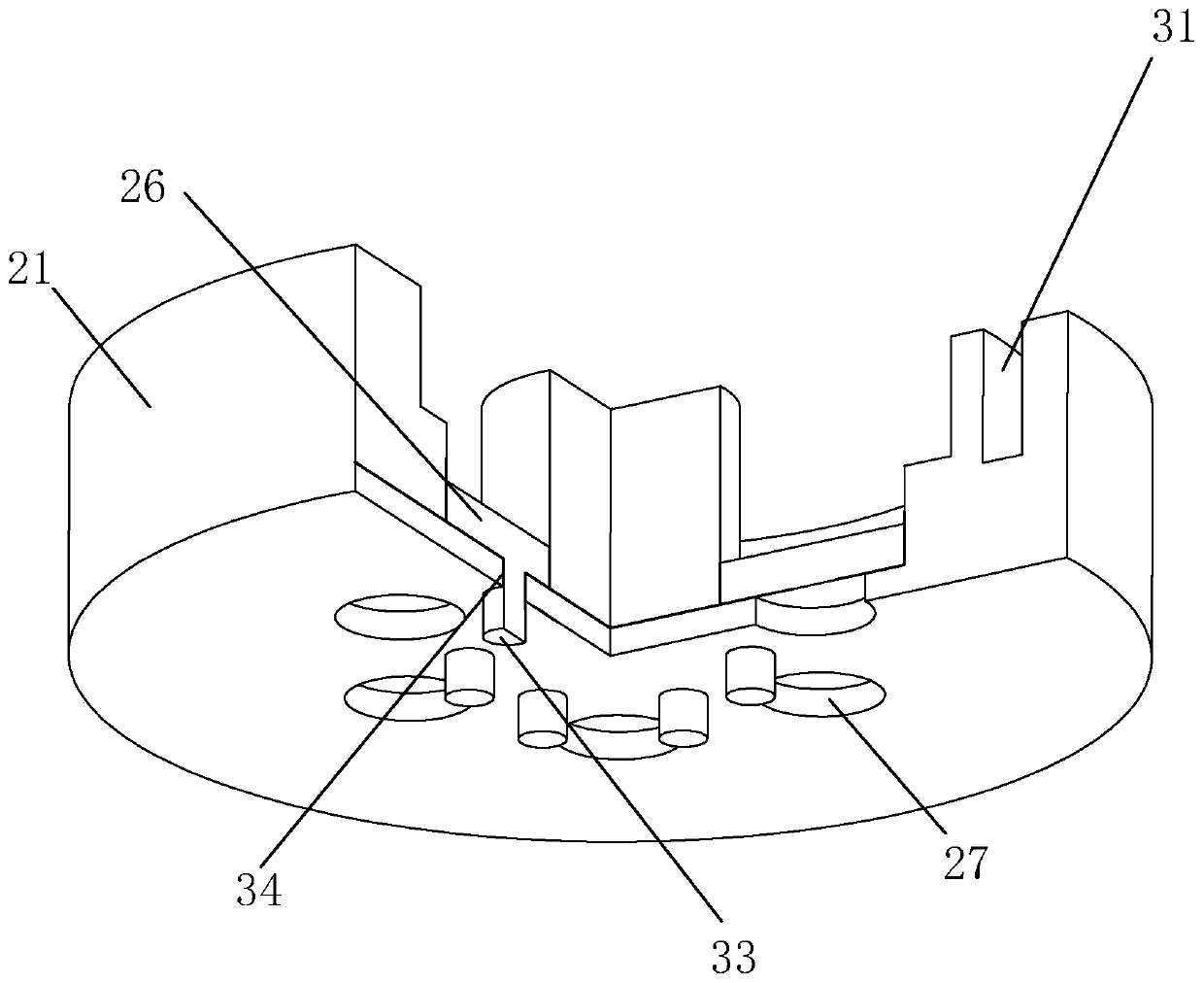

[0035]Embodiment 1: a kind of forming process of the diamond roller of dressing wheel, it is characterized in that, comprises the following steps:

[0036] Step 1. Put the diamond powder and additives into the ring-shaped groove 24 of the forming mold, press them to a thickness of 1mm and a width of 3mm, and then carry out microwave sintering. The sintering temperature is 1841℉, and the duration is 1h. After sintering, a composite is formed. Diamond slice 1;

[0037] Step 2, process the graphite substrate, process the placement groove 22 for the graphite core at the center of the graphite substrate, the bottom of the placement groove 22 is a lower pressure ring 26 that can move upwards, and the surface of the graphite substrate is processed for 1 side of the composite diamond sheet Placed groove 24, the groove 24 extends along the thickness direction of the ink matrix and runs through a side, and the width of the groove 24 is equal to 1 / 3rd of the width of the composite diamon...

Embodiment 2

[0042] Embodiment 2: a kind of molding process of the diamond roller of dressing wheel, it is characterized in that, comprises the following steps:

[0043] Step 1. Put the diamond powder and additives into the ring-shaped groove 24 of the forming mold, press them to a thickness of 1mm and a width of 3mm, and then carry out microwave sintering. The sintering temperature is 1853.6℉, and the duration is 1.1h. After sintering, it is formed Composite diamond sheet 1;

[0044] Step 2, process the graphite substrate, process the placement groove 22 for the graphite core at the center of the graphite substrate, the bottom of the placement groove 22 is a lower pressure ring 26 that can move upwards, and the surface of the graphite substrate is processed for 1 side of the composite diamond sheet Placed groove 24, the groove 24 extends along the thickness direction of the ink matrix and runs through a side, and the width of the groove 24 is equal to 1 / 3 to 1 / 2 of the width of the compos...

Embodiment 3

[0050] A forming process of a diamond roller for dressing a grinding wheel, is characterized in that it comprises the following steps:

[0051] Step 1. Put the diamond powder and additives into the ring-shaped groove 24 of the forming mold, press them to a thickness of 1mm and a width of 3mm, and then carry out microwave sintering. The sintering temperature is 1850℉, and the duration is 1.05h. After sintering, it is formed Composite diamond sheet 1;

[0052] Step 2, process the graphite substrate, process the placement groove 22 for the graphite core at the center of the graphite substrate, the bottom of the placement groove 22 is a lower pressure ring 26 that can move upwards, and the surface of the graphite substrate is processed for 1 side of the composite diamond sheet Placed groove 24, the groove 24 extends along the thickness direction of the ink matrix and runs through a side, and the width of the groove 24 is equal to 1 / 2 of the width of the composite diamond sheet 1; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com