Room temperature intrinsic self-repairing elastomer material with super ductility and preparation method of room temperature intrinsic self-repairing elastomer material

An elastomer material and self-healing technology, applied in the field of polymer materials, can solve problems such as the inability to achieve self-healing at room temperature and limit the practical application of materials, and achieve excellent self-healing function, easy operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

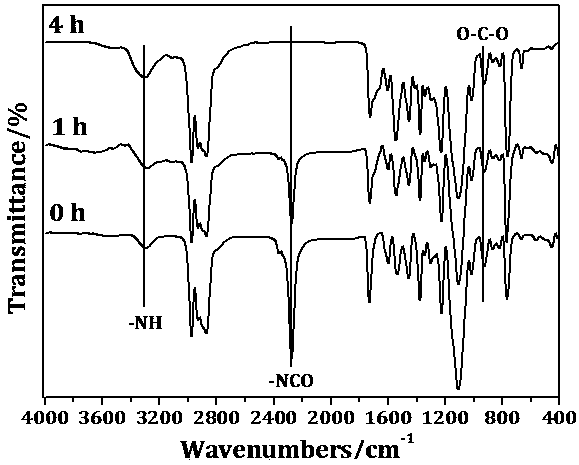

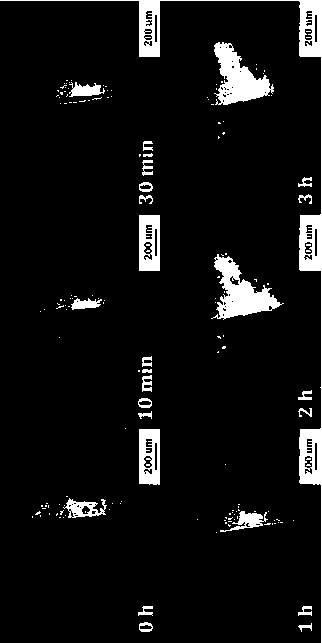

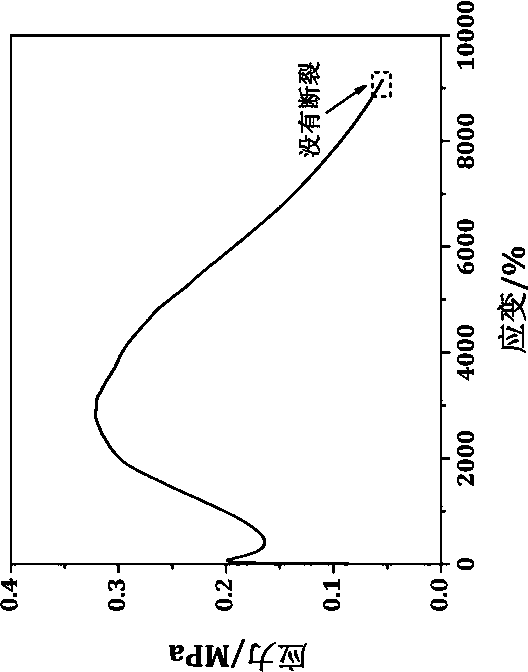

[0030] A room temperature intrinsically self-healing elastomeric material with ultra-ductility, prepared from polycondensation of 1-(3-aminopropyl)imidazole, toluene diisocyanate-terminated polypropylene glycol, triamino-terminated polypropylene glycol, and zinc chloride , wherein the molar ratio of toluene diisocyanate-terminated polypropylene glycol, 1-(3-aminopropyl) imidazole and triamino-terminated polypropylene glycol is 2:1:1, and the molar ratio of zinc ions to imidazole groups is 1: 3.

[0031] The polypropylene glycol structural formula of described toluene diisocyanate termination is as follows:

[0032]

[0033] Wherein, the molecular weight of toluene diisocyanate-terminated polypropylene glycol is 2300.

[0034] The polypropylene glycol structural formula of described triamino-terminated is as follows:

[0035]

[0036] Wherein, the molecular weight of the triamino-terminated polypropylene glycol is 440.

Embodiment 2

[0038] A room temperature intrinsically self-healing elastomeric material with ultra-ductility, which is formed by polycondensation of 1-(3-aminopropyl)imidazole, toluene diisocyanate-terminated polypropylene glycol, triamino-terminated polypropylene glycol, and trifluoromethanesulfonic acid Zinc, wherein the molar ratio of toluene diisocyanate-terminated polypropylene glycol, 1-(3-aminopropyl)imidazole and triamino-terminated polypropylene glycol is 2:1:1, and the molar ratio of zinc ions to imidazole groups It is 1:4.

[0039] The polypropylene glycol structural formula of described toluene diisocyanate termination is as follows:

[0040]

[0041] Wherein, the molecular weight of toluene diisocyanate-terminated polypropylene glycol is 2300.

[0042] The polypropylene glycol structural formula of described triamino-terminated is as follows:

[0043]

[0044] Wherein, the molecular weight of the triamino-terminated polypropylene glycol is 440.

Embodiment 3

[0046] A room temperature intrinsically self-healing elastomeric material with ultra-ductility, prepared from polycondensation of 1-(3-aminopropyl)imidazole, toluene diisocyanate-terminated polypropylene glycol, triamino-terminated polypropylene glycol, and zinc perchlorate The molar ratio of toluene diisocyanate-terminated polypropylene glycol, 1-(3-aminopropyl) imidazole and triamino-terminated polypropylene glycol is 2:1:1, and the molar ratio of zinc ions to imidazole groups is 1 :4.

[0047] The polypropylene glycol structural formula of described toluene diisocyanate termination is as follows:

[0048]

[0049] Wherein, the molecular weight of toluene diisocyanate-terminated polypropylene glycol is 2300.

[0050] The polypropylene glycol structural formula of described triamino-terminated is as follows:

[0051]

[0052] Wherein, the molecular weight of the triamino-terminated polypropylene glycol is 440.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com