Simple-substance amorphous palladium and preparing method and application thereof

An elemental palladium and amorphous technology, applied in the field of elemental amorphous palladium and its preparation, can solve the problems of high cooling rate and certain requirements for material size, and achieve high stability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

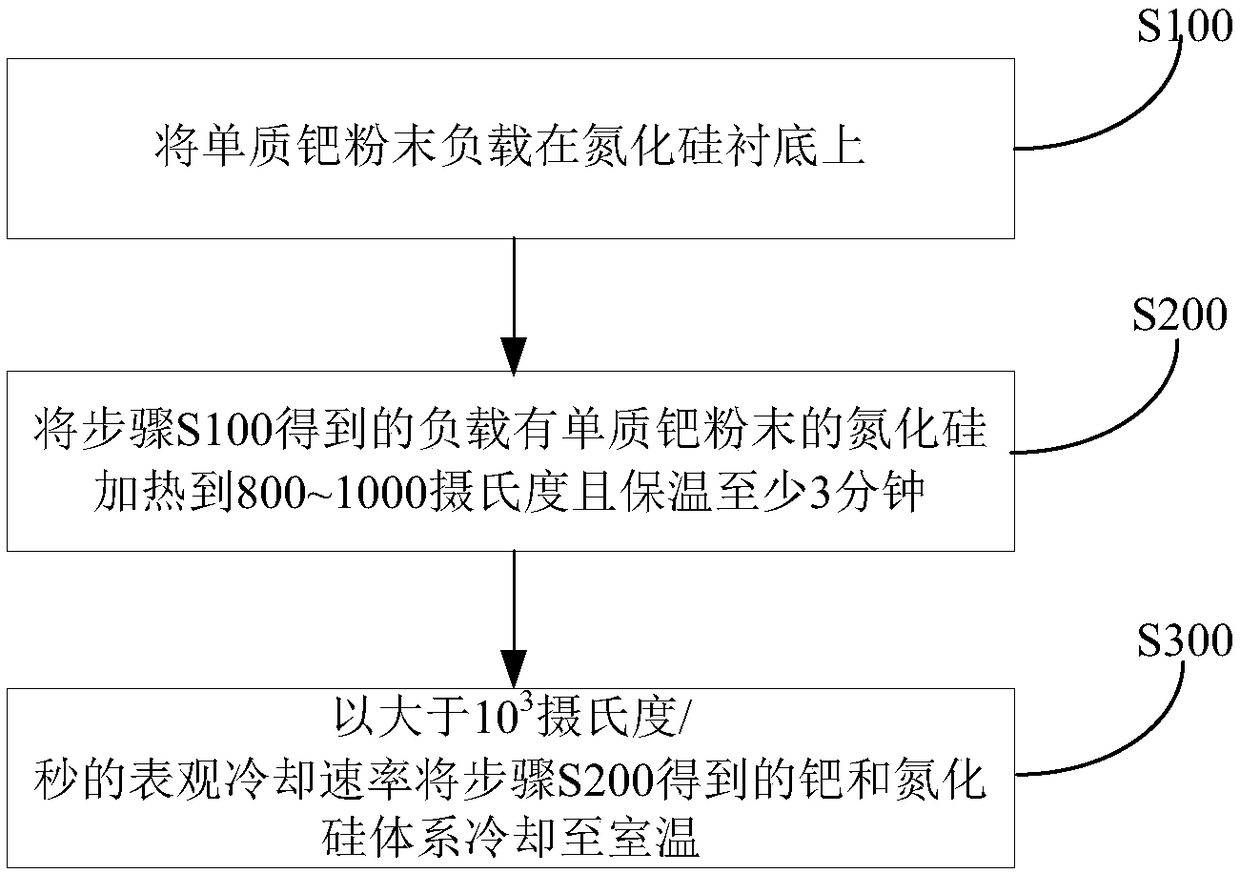

[0021] In one aspect of the present invention, the present invention provides a preparation method of elemental amorphous palladium. According to an embodiment of the present invention, refer to figure 1 , the method includes:

[0022] S100: Loading elemental palladium powder on a silicon nitride substrate

[0023] In this step, the elemental palladium powder can be purchased from commercial sources or synthesized by physical and chemical methods, and the crystal structure of the elemental palladium powder can be a face-centered cubic structure, for example, the elemental palladium powder of the face-centered cubic structure can be prepared by adopting the following steps Obtained: At room temperature, 0.1050g of PVP, 0.0600g of citric acid, and 0.0600g of L-ascorbic acid were dissolved in 8mL of deionized water, and the mixed aqueous solution was transferred to a three-necked flask and heated to 120°C for 5 minutes. At the same time, weigh 0.0650g K at room temperature 2 P...

Embodiment

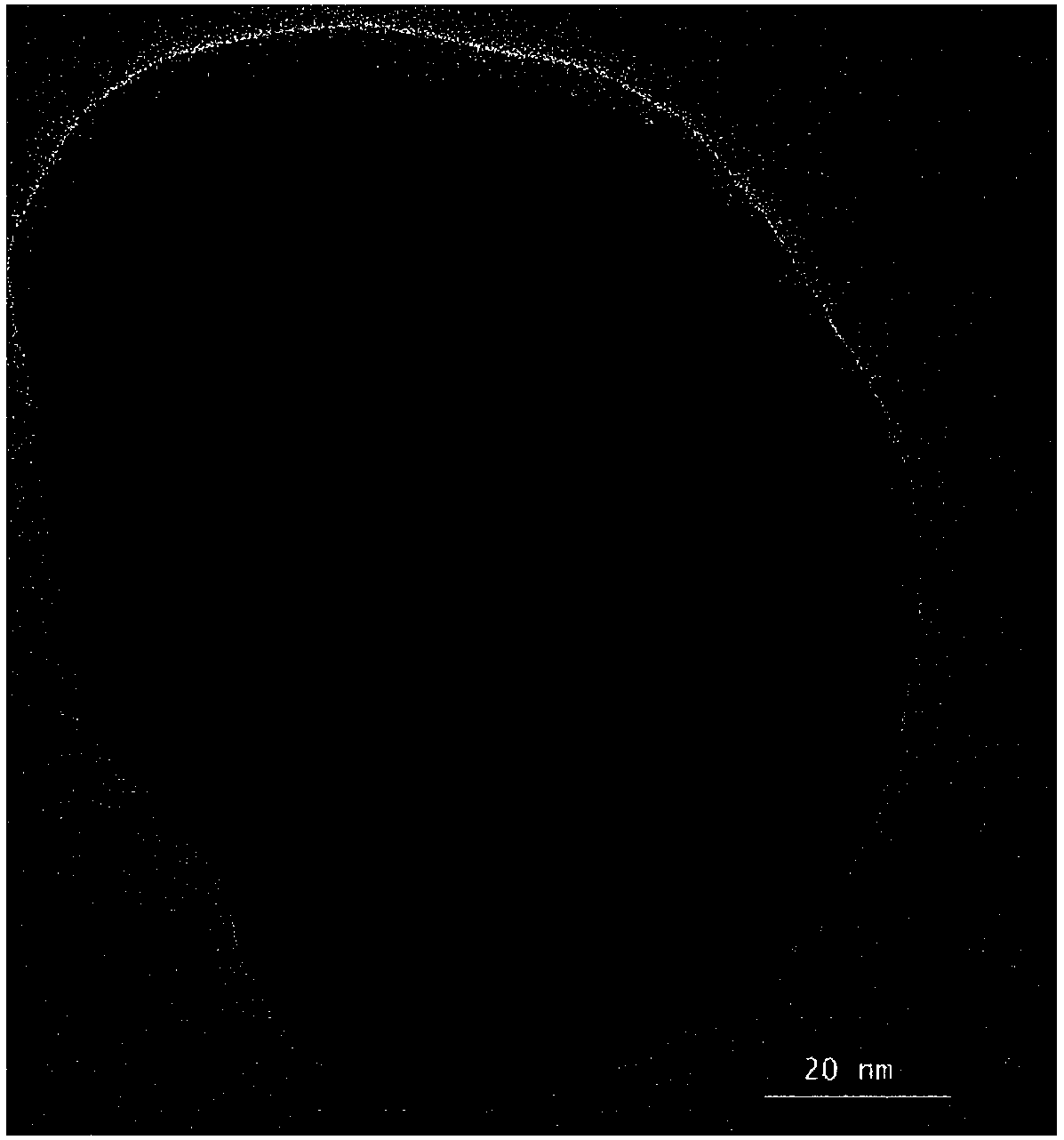

[0037] At room temperature, 0.1050g of PVP, 0.0600g of citric acid, and 0.0600g of L-ascorbic acid were dissolved in 8mL of deionized water, and the mixed aqueous solution was transferred to a three-necked flask and heated to 120°C for 5 minutes. At the same time, weigh 0.0650gK at room temperature 2 PdCl 4 Dissolve in 3mL of deionized water, and inject it into a three-necked flask of mixed aqueous solution at a rate of 360mL / h, and react at 120°C for 3 hours. The obtained product is washed with acetone and deionized water to remove residual PVP. Obtain metal elemental palladium powder with a face-centered cubic structure; then mix the obtained elemental palladium powder with ethanol and ultrasonically disperse for 15 minutes to obtain a dispersion, then use a pipette gun to take the dispersed liquid droplet on the NanoEx-i-v MEMS chip produced by Thermo Fisher above; and the sample was heated to 800 ° C and kept for 5 min, and then rapidly cooled to room temperature at a coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com