Visual polymer flow regulation oil washing experiment unit

A kind of experimental device and polymer technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems that cannot reflect the development effect of remaining oil and cannot correctly reflect the distribution of remaining oil, etc., and achieves a simple and practical structure strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

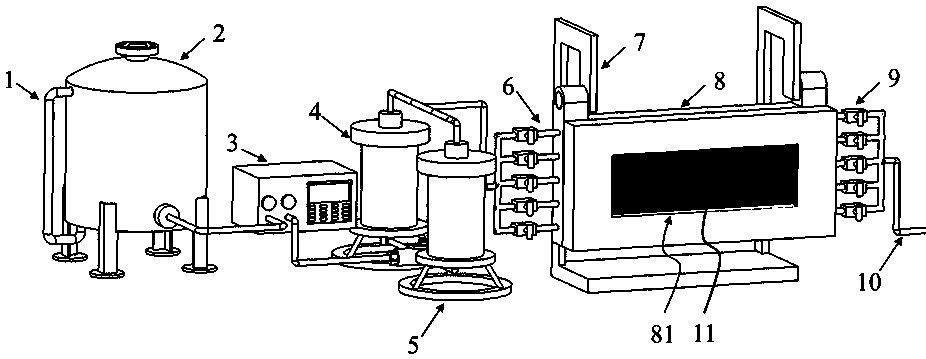

[0037] Such as figure 1 As shown in the figure, a visual experimental device for polymer flow regulation and oil washing, including a liquid tank 2, an advection pump 3, a polymer intermediate container 4, a water intermediate container 5, a hole density control valve group 6, a bracket 7, and a box-type holder 8. The discharge valve group 9, the discharge pipe 10 and the remaining oil distribution physical model 11, the inlet of the advection pump 3 is connected to the liquid tank 2, and the outlet of the advection pump 3 and the hole density control valve group 6 are installed in parallel. The intermediate container 4 and the water intermediate container 5, the remaining oil distribution physical model 11 is installed in the box-type holder 8, the inlet on the box-type holder 8 is connected with the hole density control valve group 6, and the outlet is connected with the discharge The valve group 9 communicates, and the discharge pipe 10 is connected with the discharge valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com