Installation method of water-cooling electric induction module installed on printed wiring board and application thereof

A technology for printed circuit boards and inductors, which is used in transformer/inductor cooling, electrical components, electrical equipment structural parts, etc., and can solve the problems of inability to meet the power density of power electronic conversion equipment, unfavorable use of confined spaces, and single function. , to achieve the effect of convenient disassembly, easy maintenance and replacement, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

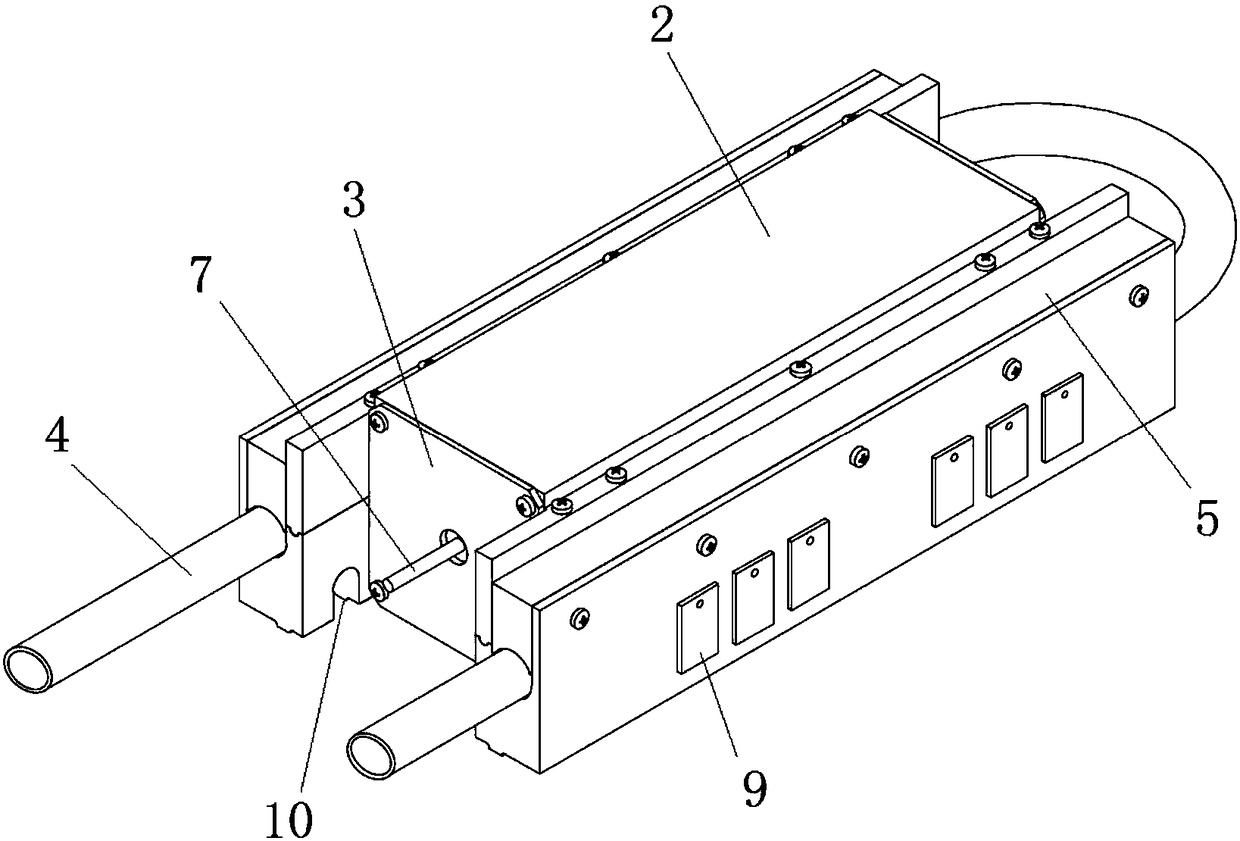

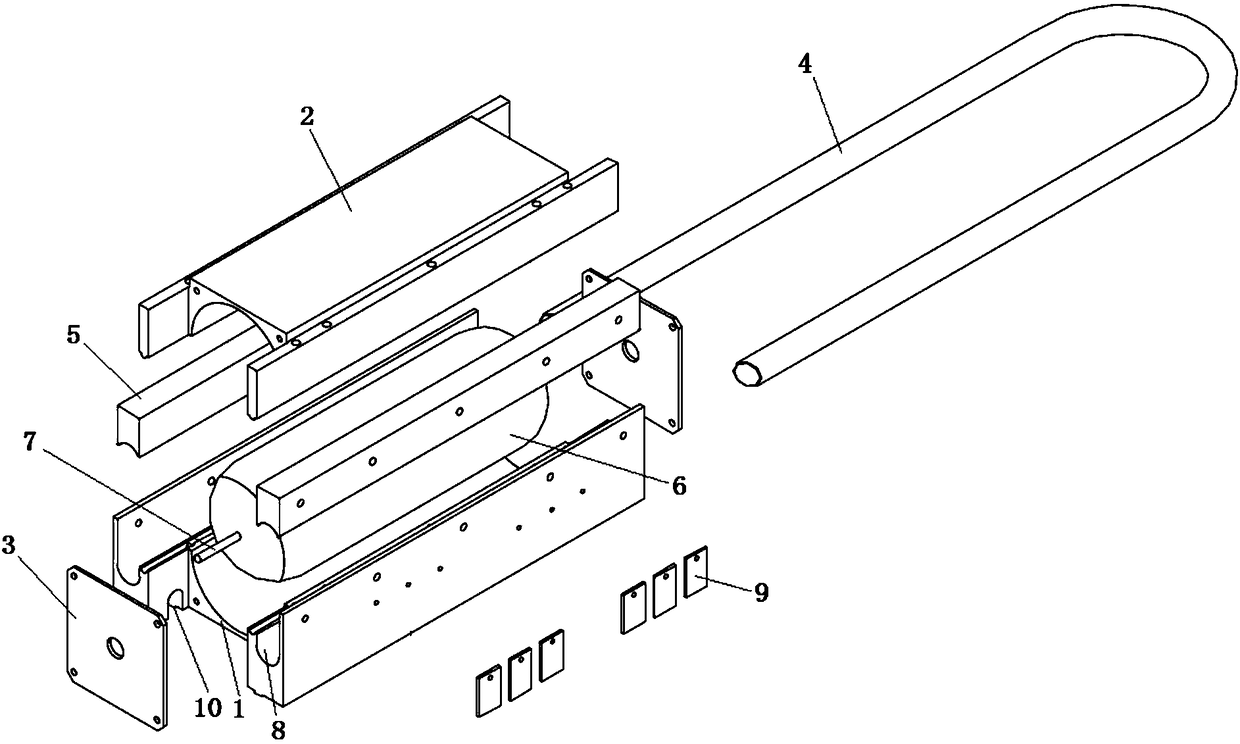

[0037] A water-cooled inductance module installed on a printed circuit board, including a base 1 and an upper cover 2 oppositely arranged, the base 1 and the upper cover 2 are respectively formed with semicircular concave cavities, and the buckle is formed to be connected with the cylindrical resin pot. The cylindrical cavity corresponding to the sealing inductor 6, the resin potting inductor 6 is set in the cavity, the two ends of the cavity are open, sealed with the end cover 3, and the upper cover 2 and the base 1 are clamped with pure copper The water-cooled tube 4 is prepared and the water-cooled tube 4 is isolated from the cavity, and the inductor lead-out wires 7 provided at both ends of the resin-encapsulated inductor 6 pass through the end cover 3;

[0038] The shape of the water-cooled pipe 4 is U-shaped, and the straight pipe bodies on both sides of the U-shape are respectively fixed by fixing blocks 5, between the fixing block 5 and the base 1, between the upper cov...

Embodiment 2

[0042] A water-cooled inductance module installed on a printed circuit board, including a base 1 and an upper cover 2 oppositely arranged, the base 1 and the upper cover 2 are respectively formed with semicircular concave cavities, and the buckle is formed to be connected with the cylindrical resin pot. Sealing the cylindrical cavity corresponding to the inductor 6, the resin potting inductor 6 is set in the cavity, one end of the cavity is open, sealed with the end cap 3, and the other end is closed;

[0043]Both ends of the resin-encapsulated inductor 6 are respectively provided with inductor lead-out wires 7. In order to facilitate the extraction of the inductor lead-out wires 7, outlet holes are correspondingly set on the end cover 3 of the cavity, and the two sides of the base 1 are symmetrically provided with openings upward U-shaped groove 8, the U-shaped groove 8 is made integrally with the base 1, and a water-cooled tube 4 made of aluminum alloy is placed in the U-shap...

Embodiment 3

[0048] A water-cooled inductance module installed on a printed circuit board, including a base 1 and an upper cover 2 oppositely arranged, the base 1 and the upper cover 2 are respectively formed with semicircular concave cavities, and the buckle is formed to be connected with the cylindrical resin pot. The cylindrical cavity corresponding to the sealing inductor 6, the resin potting inductor 6 is set in the cavity, the two ends of the cavity are open, sealed with the end cover 3, and the upper cover 2 and the base 1 are clamped with pure copper The water-cooled tube 4 is prepared and the water-cooled tube 4 is isolated from the cavity, and the inductor lead-out wires 7 provided at both ends of the resin-encapsulated inductor 6 pass through the end cover 3 .

[0049] The water-cooled inductance module is applied in the power electronic conversion circuit, which can meet the heat dissipation requirements of the power devices in the power electronic conversion circuit, and can re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com