Jetting duct-type composite sheet-type electric pottery hot air tea baking machine

A technology of composite sheet and pottery hot air, which is applied in tea treatment before extraction, etc., can solve problems such as bad damage to human body, low heat utilization rate, environmental pollution, etc., and achieve the effects of automatic temperature control, power saving, and convenient use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

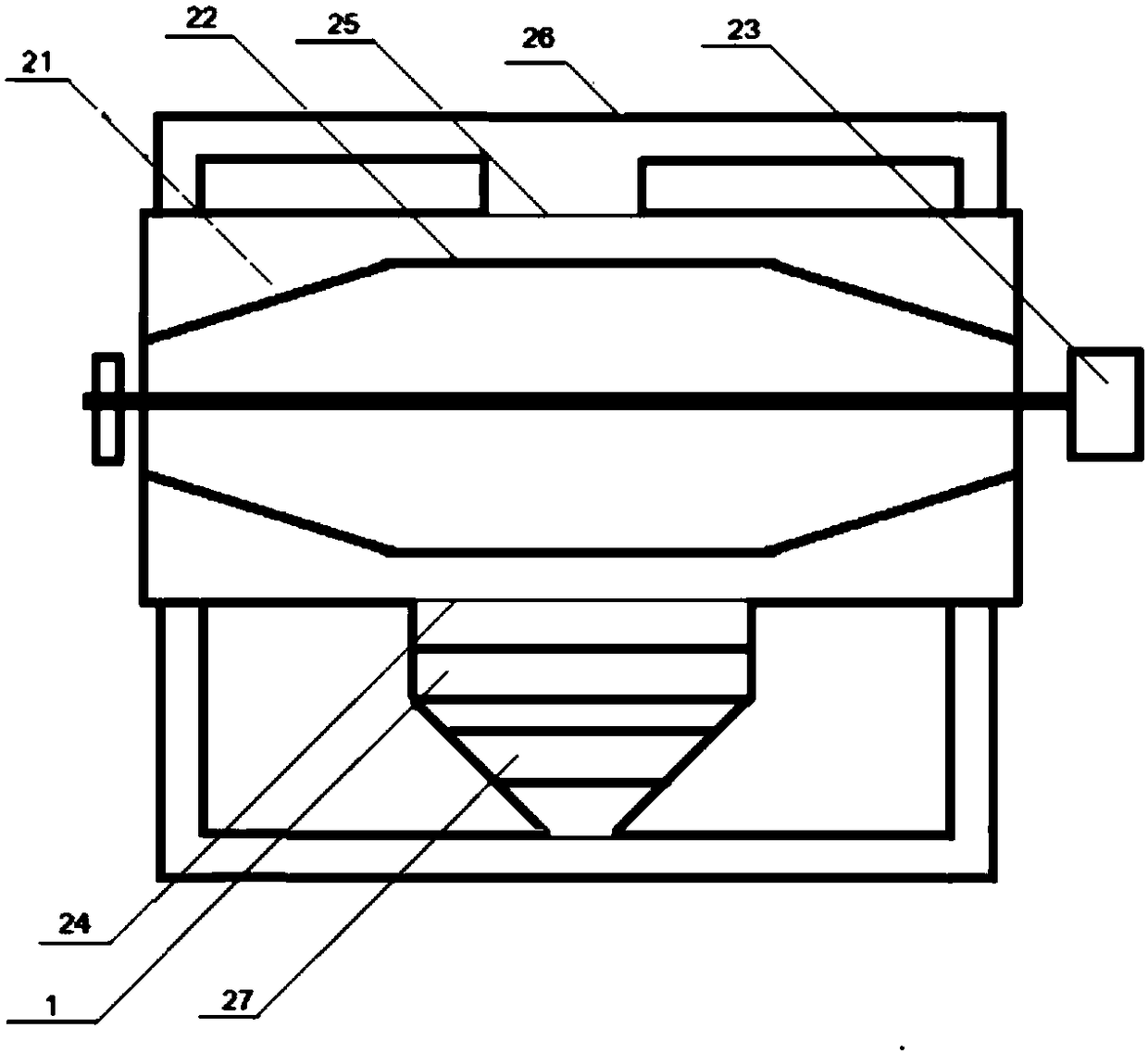

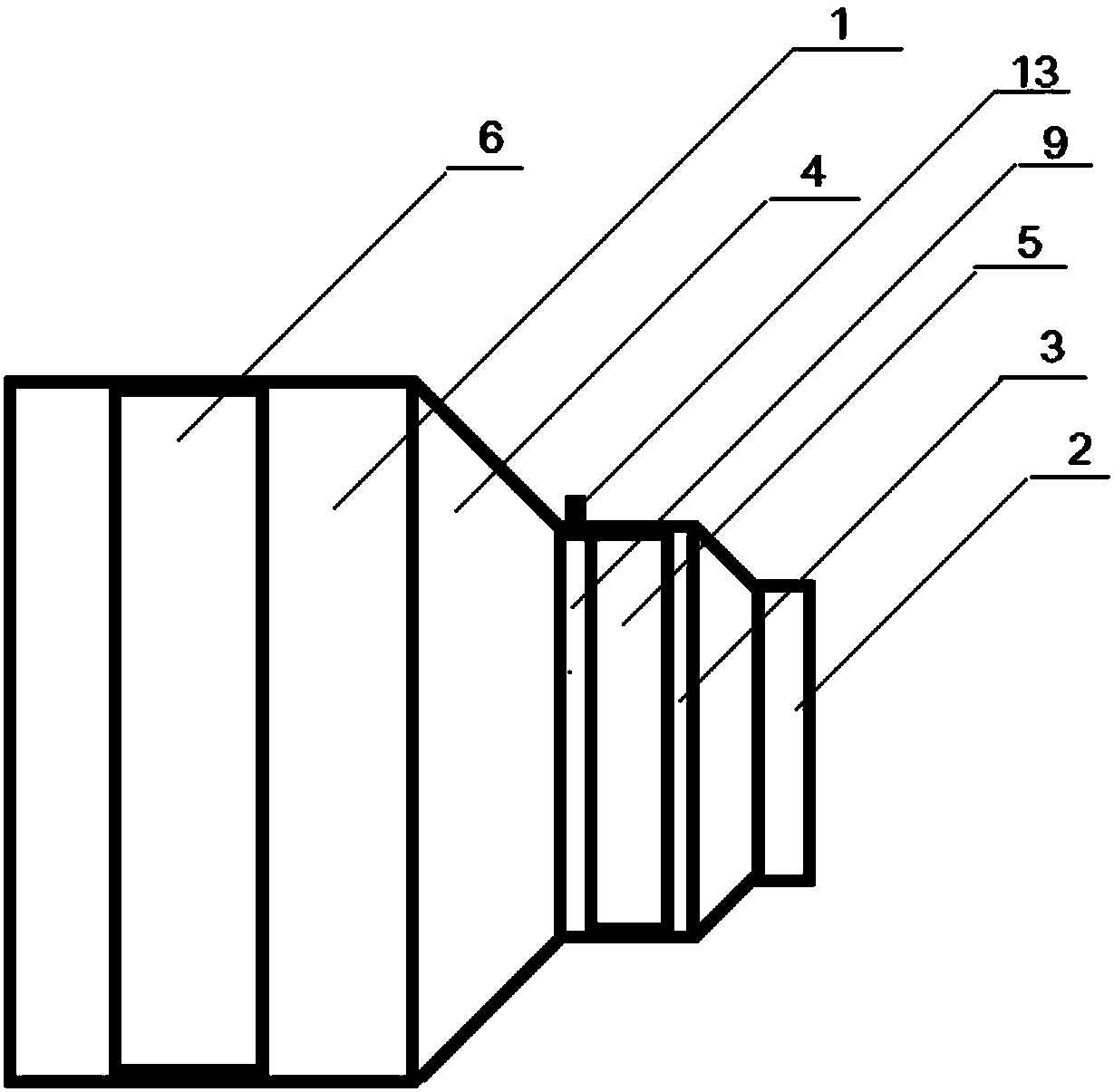

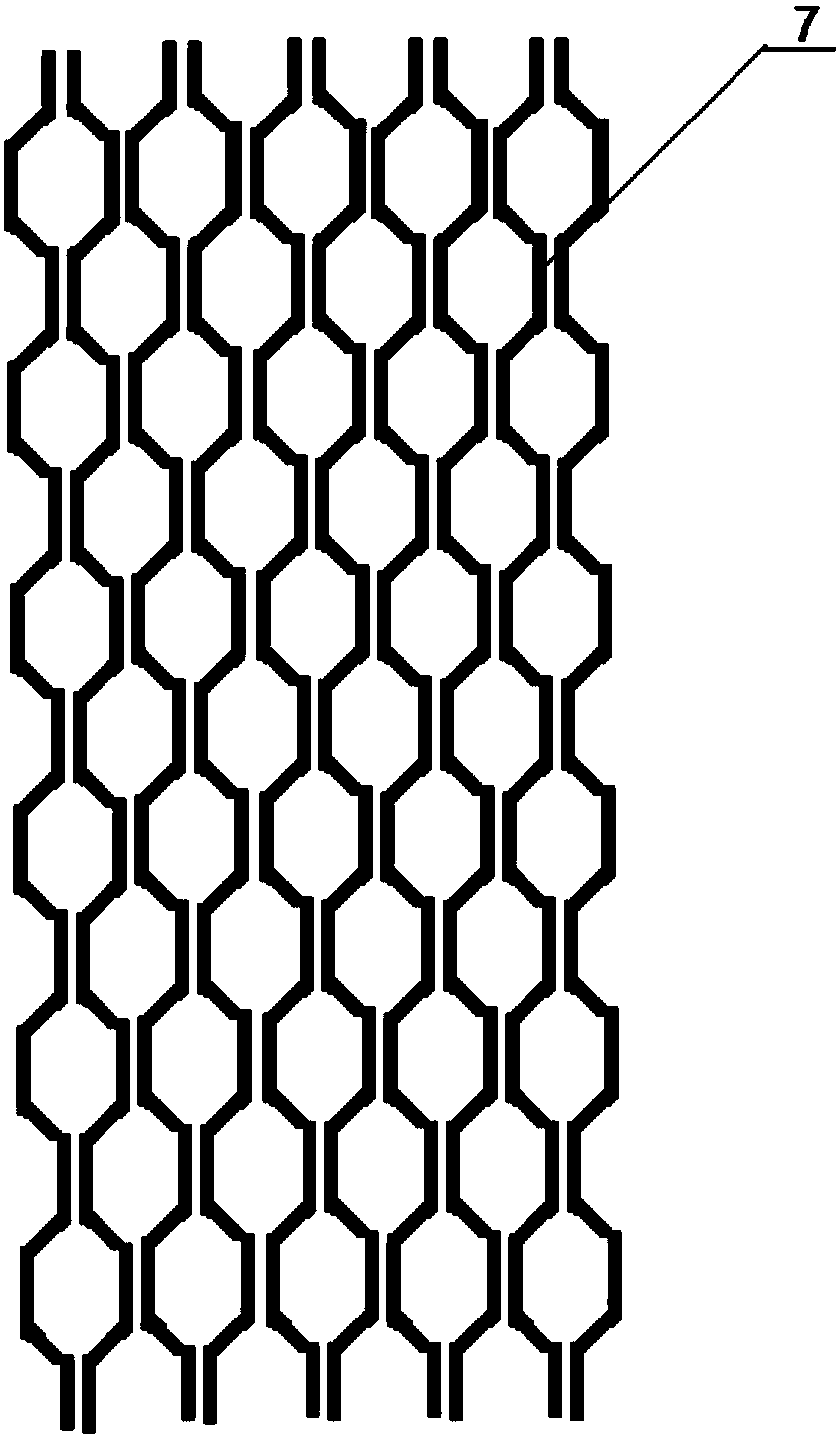

[0026] Embodiment 1: A blowing duct type composite plate type electric pottery hot air tea drying machine, the re-drying machine body 21 is provided with a drum 22 for drying tea, the drum 22 is connected to the motor 23 through the central shaft, and the re-drying An air outlet 25 is provided on the top of the machine body 21, and a hot air inlet 24 for blowing hot air inward is provided on the re-dryer main body 21. The hot air inlet 24 is connected to the electric heater body 1 that provides heat inward, and the pipe 26 is connected to the air outlet. 25, the pipeline 26 divides the gas coming out from the air outlet 25 into two paths, and guides the gas from the two ends of the shell of the re-dryer body 21 to its lower part, and then merges into the fan 27, and the pipeline 26 discharges the gas from the re-dryer body 21 The gas is introduced into the electric heater body 1 for reheating, and the gas enters the re-dryer body 21 from the hot air inlet 24; the electric heate...

Embodiment 2

[0027] Embodiment 2: A blowing duct type composite plate type electric pottery hot air tea drying machine, the re-drying machine body 21 is provided with a drum 22 for drying tea, the drum 22 is connected to the motor 23 through the central shaft, and the re-drying An air outlet 25 is provided on the top of the machine body 21, and a hot air inlet 24 for blowing hot air inward is provided on the re-dryer main body 21. The hot air inlet 24 is connected to the electric heater body 1 that provides heat inward, and the pipe 26 is connected to the air outlet. 25, the pipeline 26 divides the gas coming out from the air outlet 25 into two paths, and guides the gas from the two ends of the shell of the re-dryer body 21 to its lower part, and then merges into the fan 27, and the pipeline 26 discharges the gas from the re-dryer body 21 The gas is introduced into the electric heater body 1 for reheating, and the gas enters the re-dryer body 21 from the hot air inlet 24; the electric heate...

Embodiment 3

[0028]Embodiment 3: A blowing duct type composite plate type electric pottery hot air tea drying machine, the re-drying machine body 21 is provided with a drum 22 for drying tea, the drum 22 is connected to the motor 23 through the central shaft, and the re-drying An air outlet 25 is provided on the top of the machine body 21, and a hot air inlet 24 for blowing hot air inward is provided on the re-dryer main body 21. The hot air inlet 24 is connected to the electric heater body 1 that provides heat inward, and the pipe 26 is connected to the air outlet. 25, the pipeline 26 divides the gas coming out from the air outlet 25 into two paths, and guides the gas from the two ends of the shell of the re-dryer body 21 to its lower part, and then merges into the fan 27, and the pipeline 26 discharges the gas from the re-dryer body 21 The gas is introduced into the electric heater body 1 for reheating, and the gas enters the re-dryer body 21 from the hot air inlet 24; the electric heater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com