Automatic cylinder end cover tapping machining line

An automatic line and cylinder technology, applied in the direction of metal processing, metal processing equipment, thread cutting machine, etc., can solve the problems of inability to realize automatic unmanned operation, long production cycle of cylinder end cover, increase the cost of enterprise employment, etc., to shorten the production cycle, The effect of speeding up production tempo and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

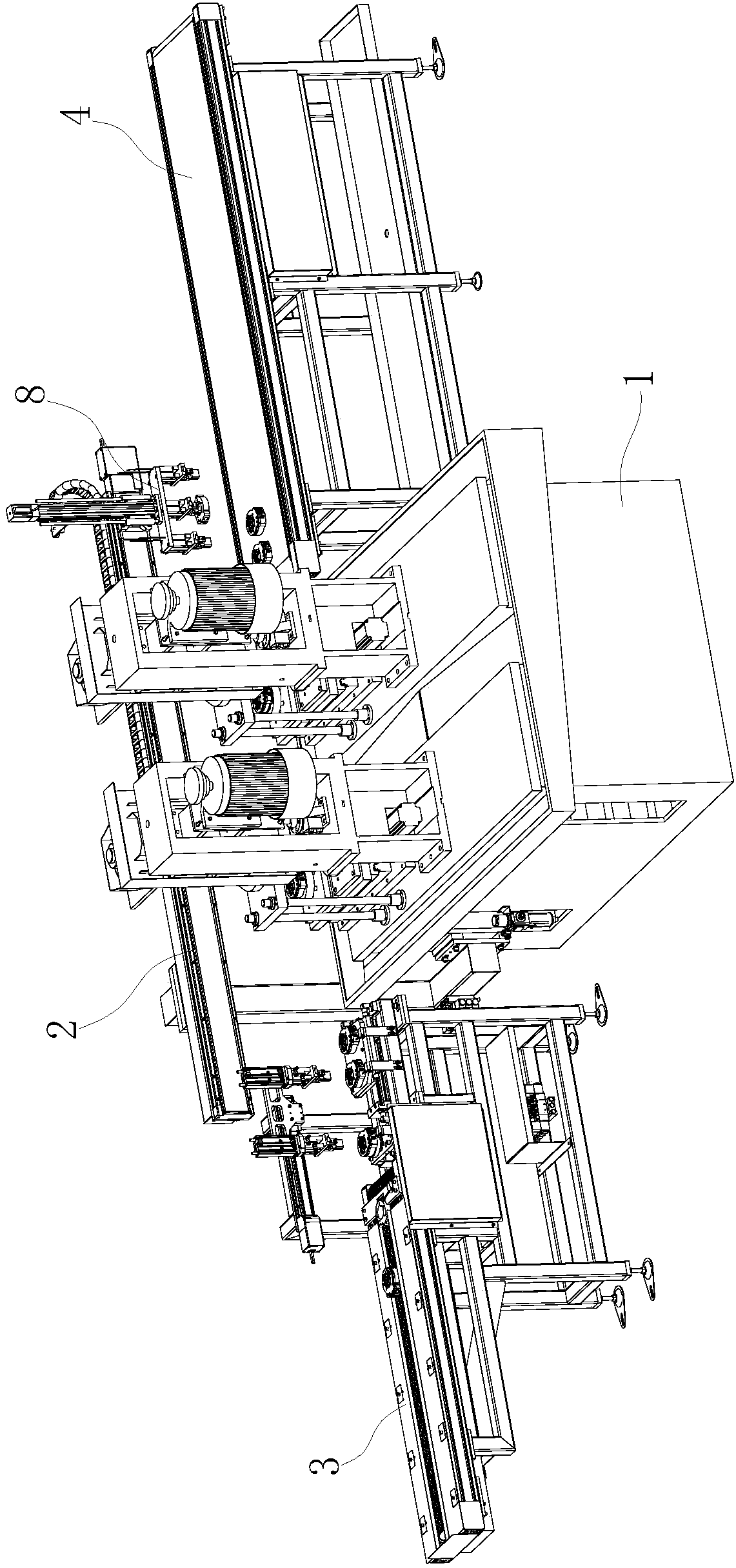

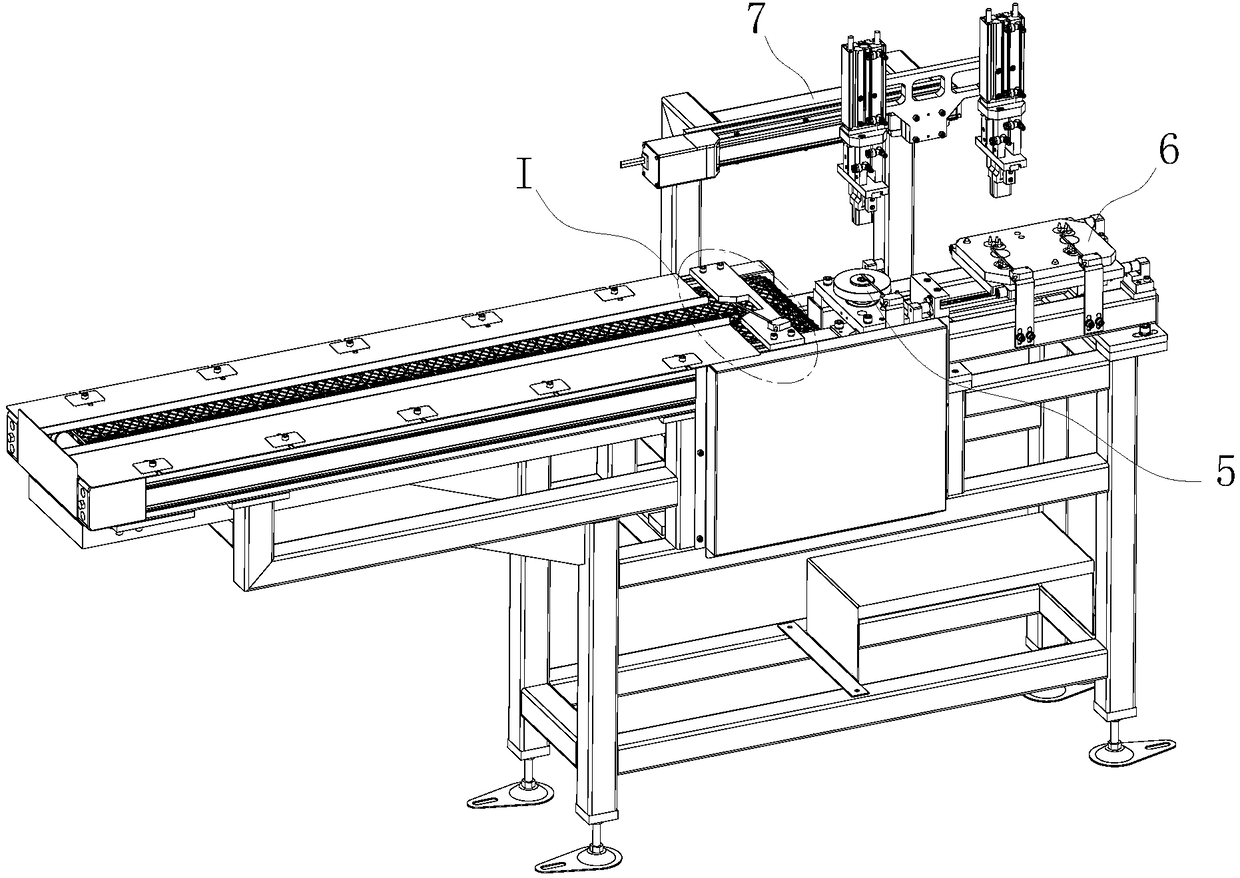

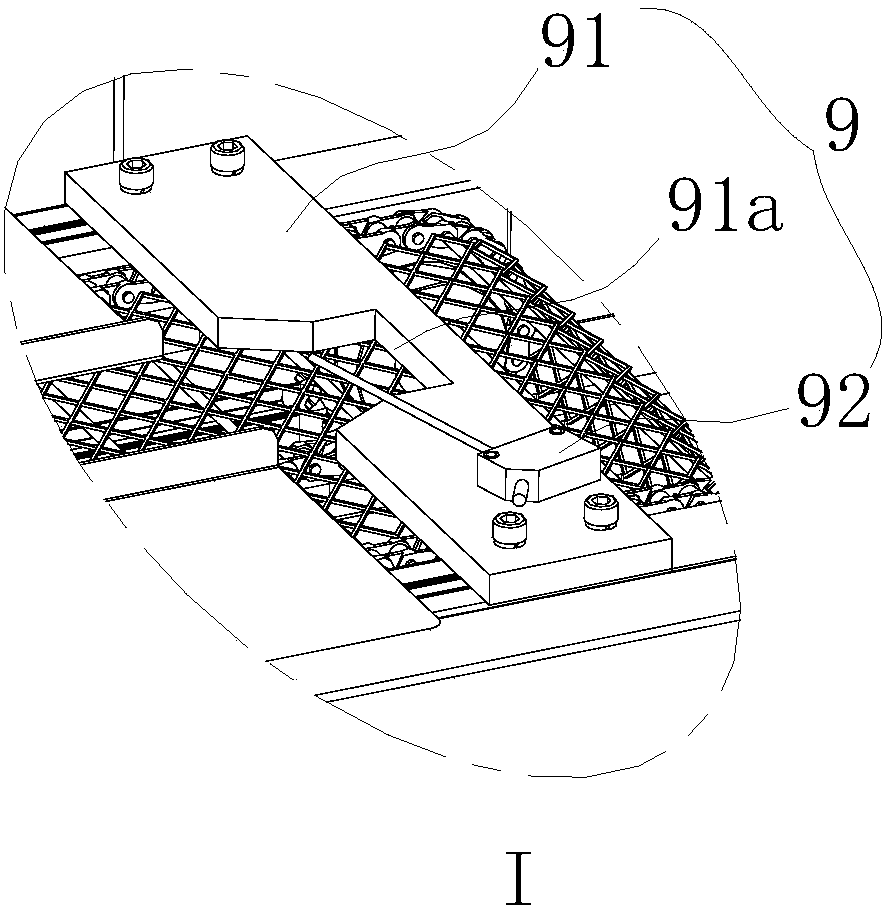

[0028] Such as Figure 1 to Figure 7 As shown, an automatic line for cylinder end cap tapping processing includes a double-station tapping machine 1 and a control system. The processing position of the double-station tapping machine 1 is provided with a truss robot 2, and the truss robot 2 The two ends are respectively provided with a feeding conveying line 3 and a feeding conveying line 4. The end of the feeding conveying line 3 close to the truss robot 2 is provided with a rotary positioning mechanism 5 and a positioning jig 6 in sequence along the conveying direction. The conveying line 3 is provided with a shifting and cutting mechanism 7 for grabbing the cylinder end cap, and the truss robot 2, the rotary positioning mechanism 5, and the shifting and cutting mechanism 7 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com