A multi-degree-of-freedom motion realization device for large and medium-sized disk parts processed by barrel finishing

A technology of disc parts and degrees of freedom, which is applied to machine tools, metal processing equipment, grinding/polishing equipment, etc. suitable for grinding the edge of workpieces, and can solve the problem of multi-directional adjustable and consistent processing of large and medium-sized disc parts. To achieve the effect of ensuring all-round processing and consistent processing, solving one-time processing and inconsistency of processing quality, and improving processing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

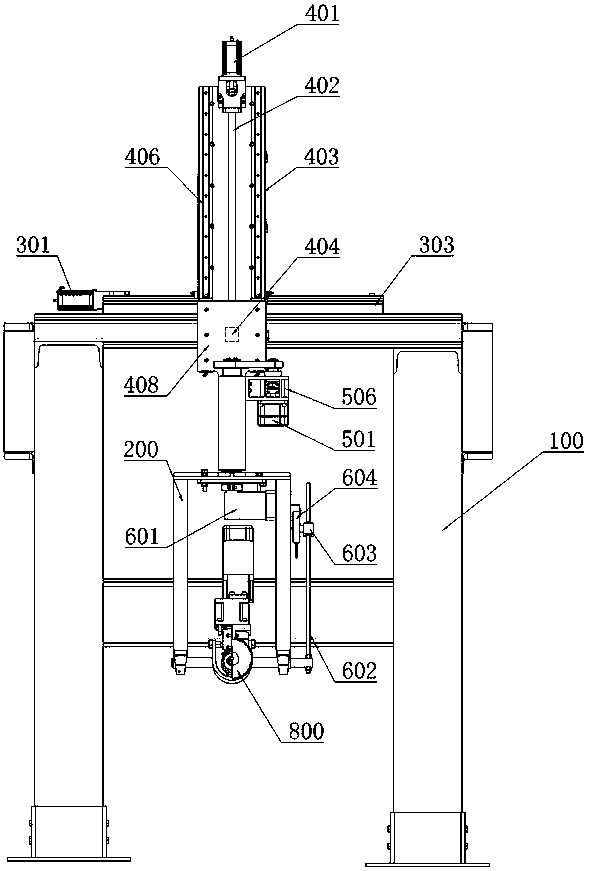

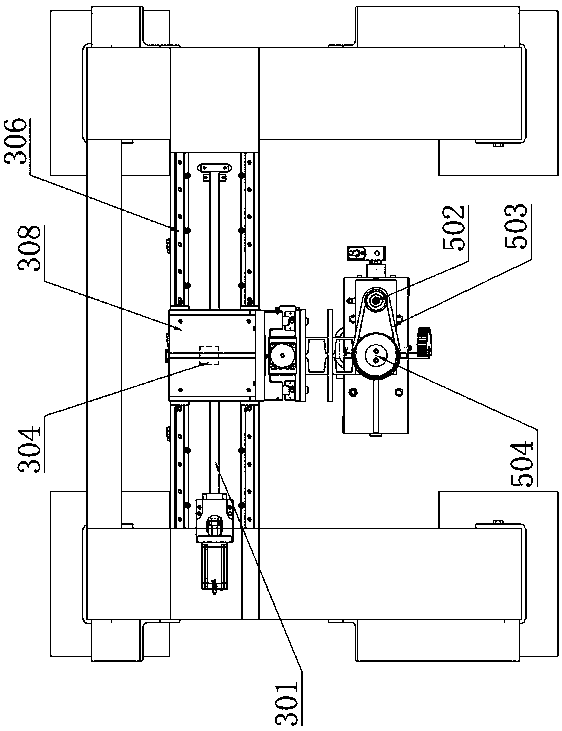

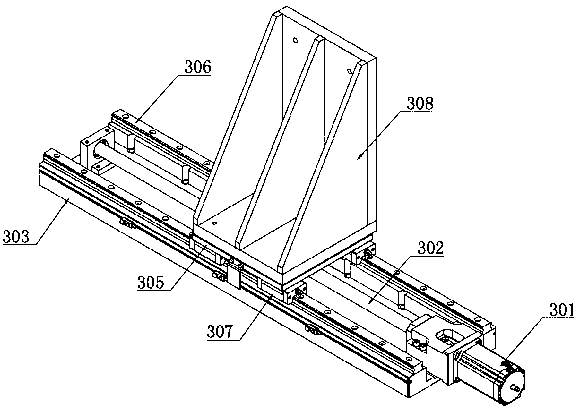

[0045] This embodiment provides a device for realizing multi-degree-of-freedom motion of large and medium-sized disc parts, such as Figure 1 to Figure 5As shown, it includes a first frame 100, a horizontal movement assembly, a vertical movement assembly, a horizontal rotation assembly, a second frame 200, and a swing assembly and a vertical rotation assembly installed on the second frame 200; the second frame 200 includes a horizontal beam and two vertical beams arranged under the horizontal beam; the horizontal moving assembly is arranged on the first frame 100, including a first motor 301, a horizontal lead screw 302, a horizontal lead screw mounting frame 303, and a horizontal lead screw Nut 304, horizontal slide table 305, the horizontal guide rail 306 that is arranged on the horizontal screw mounting frame 303, the horizontal slide table guide rail 307 that is arranged under the horizontal slide table 305 and the first connection that connects the horizontal slide table 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com