A kind of in-situ test method and in-situ test structure of deep soft rock tunnel

A technology of in-situ testing and tunneling, which is applied in earth cube drilling, mining equipment, mining equipment, etc., can solve the problems of high cost, low strength, damage, etc., to improve depth and reliability, save construction time, and reduce construction cost. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

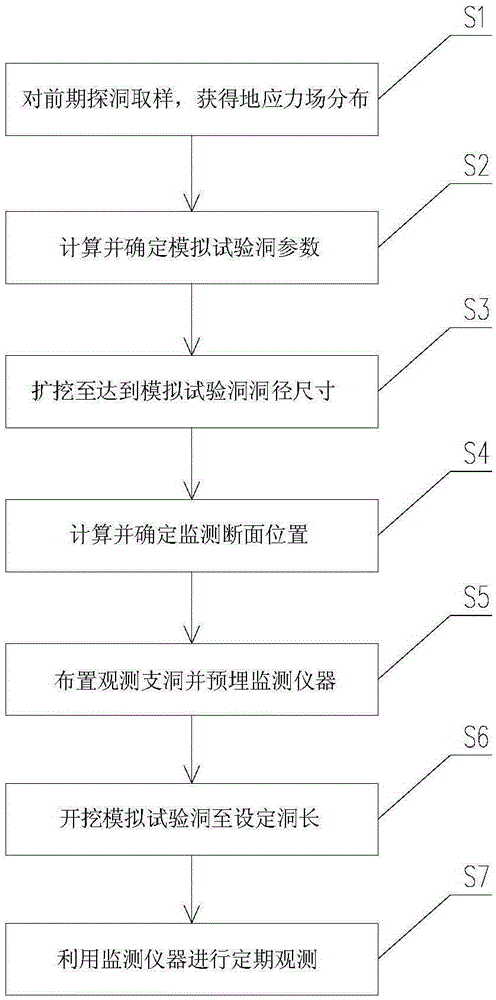

[0034] Embodiment 1, the in-situ testing method of the deep soft rock tunnel.

[0035] Refer to attached Figure 1-7 .

[0036] The in-situ testing method of deep buried soft rock tunnel of the present invention comprises the following steps:

[0037] S1. Sampling the previous cavern 1, conducting indoor rock mechanics tests, and conducting in-situ stress tests to obtain the distribution characteristics of the in-situ stress field and provide basic data for subsequent analysis.

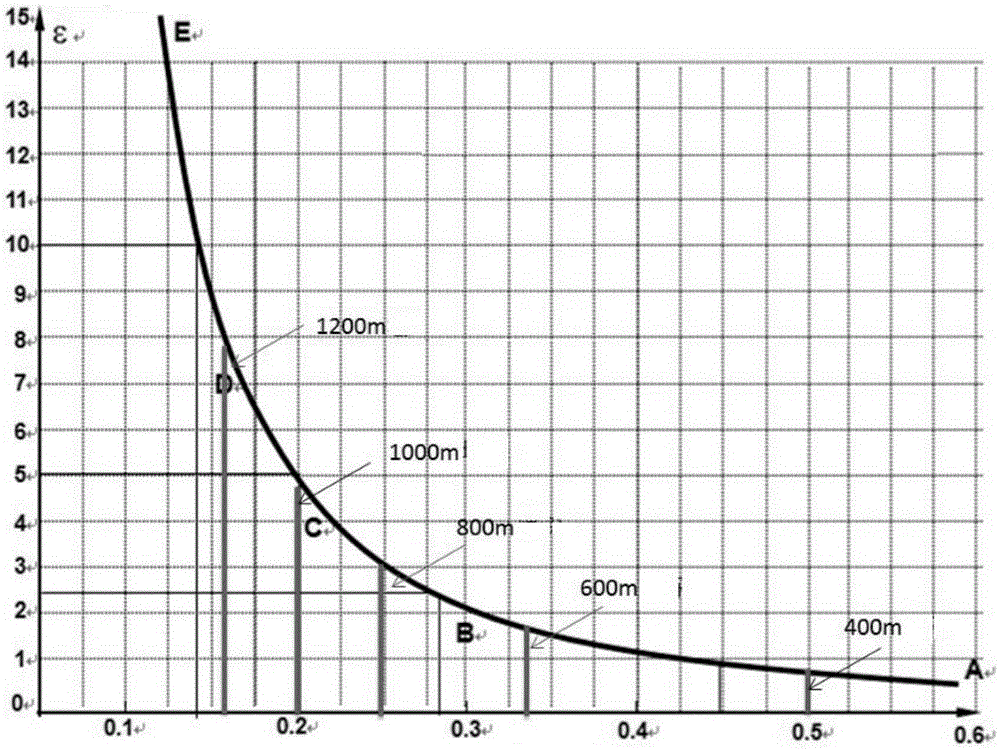

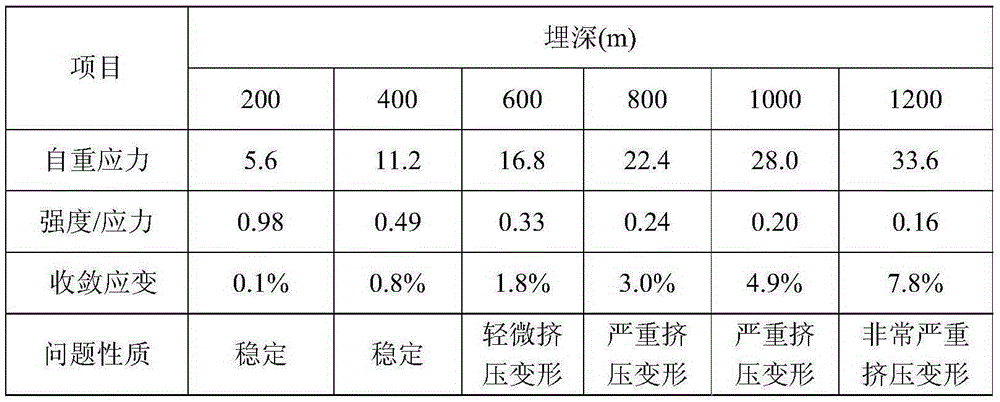

[0038] S2, calculate and determine the parameters of the simulation test hole 2, the parameters include buried depth, axis direction, hole diameter D, section shape and hole length H.

[0039] As mentioned in the background technology, excavating a simulated test tunnel with the same size as the original tunnel is not only expensive, but also difficult to meet the time requirements of the project, and if the size is too small, the surrounding rock failure phenomenon under high stress conditions cann...

Embodiment 2

[0062] Example 2, in situ test structure.

[0063] Refer to attached Figure 7-8 .

[0064] The in-situ test structure of the present invention can be excavated according to the in-situ test method in Example 1. The in-situ test structure includes a simulation test hole 2, a preliminary exploration hole 1 and an observation branch hole 5.

[0065] The simulated test hole 2 is arranged behind the preliminary exploration hole 1 of the soft rock tunnel. The parameters of the simulated test hole 2, such as buried depth, axis direction, hole diameter, cross-sectional shape and hole length, can be pre-calculated by the in-situ test method in Example 1. get.

[0066] The axial direction of the simulated test hole 2 is perpendicular to the maximum principal stress direction of the deeply buried soft rock. Generally, in order to ensure the stability of the surrounding rock in deep buried tunnels, the tunnel axis should be selected as consistent as possible with the maximum principal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com