Rotation type multilayer storing equipment for shoulder shaft type parts

A shouldered shaft and rotary technology, which is applied in the field of multi-layer storage equipment for rotary shouldered shaft parts, can solve the problems of low work efficiency and inconvenient adjustment of empty disks, so as to improve work efficiency, reduce interval time, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

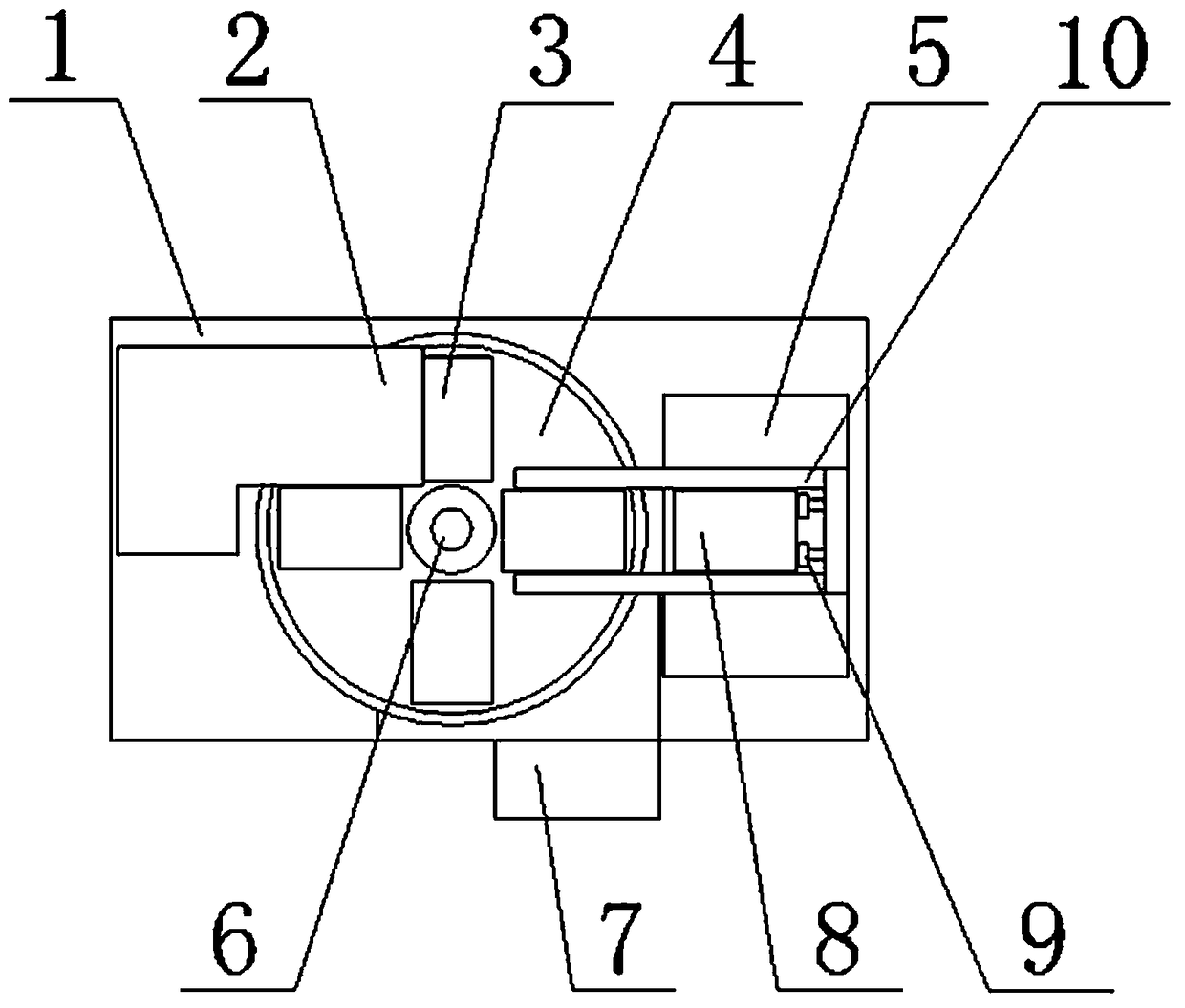

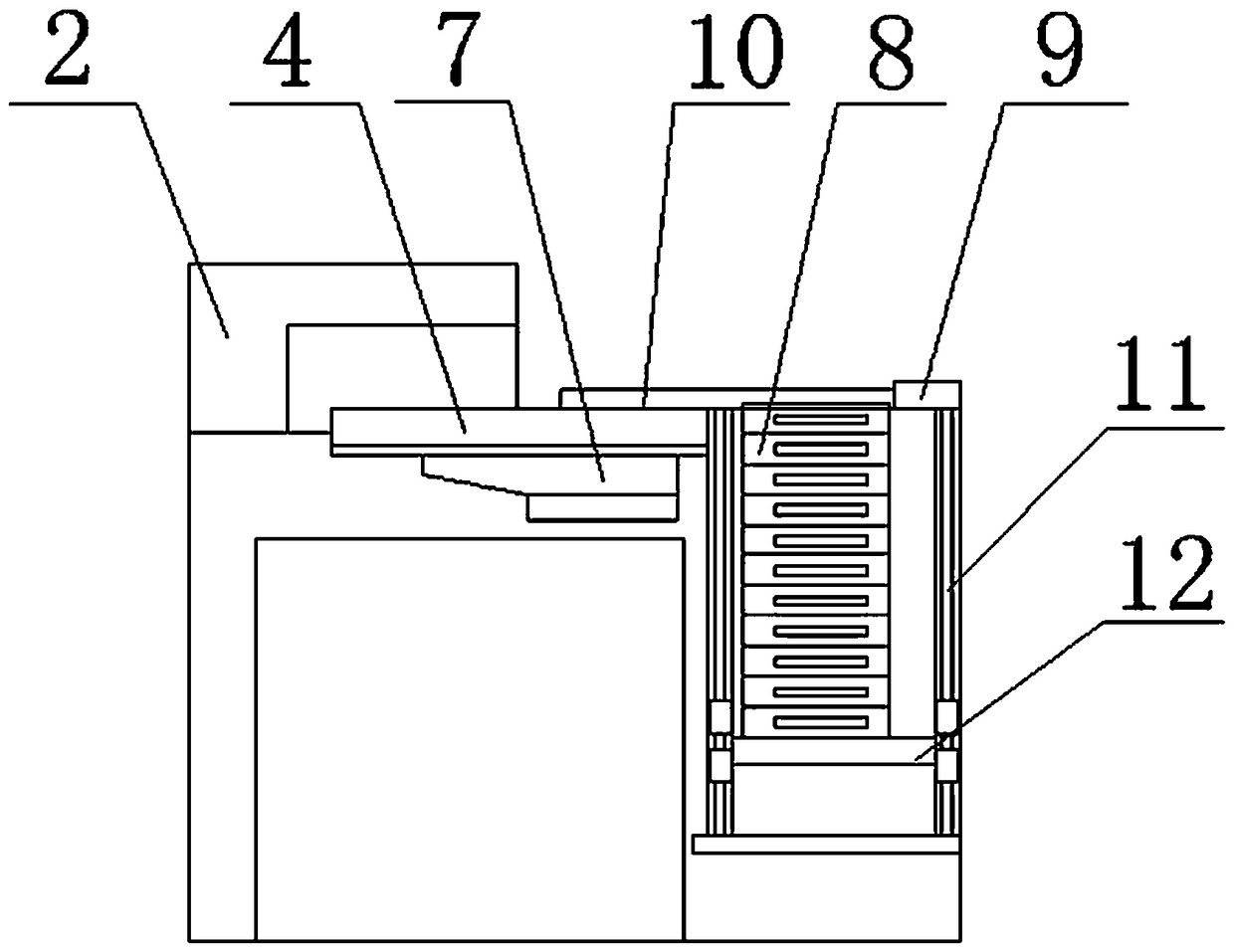

[0017] A rotary multi-layer material storage device for shouldered shaft parts, including a material insertion device 2, a rotating disk 4, and a material storage tray conveying device 5. The material insertion device 2 is arranged on the upper left side of the box body 1, and the material insertion device The right side of the device 2 is connected to the rotating disk 4, the rotating shaft 6 is arranged in the middle of the rotating disk 4, the feeding tray hole 3 is arranged on the rotating disk 4, the feeding tray outlet 7 is arranged under the rotating disk 4, and the right side of the rotating disk 4 is the material storage Disk conveying device 5, described storage tray conveying device 5 comprises guide plate 10, and guide plate 10 extends to the top of rotating disk 4, and the right side of guide plate 10 is pushing device 9, and the middle of guide plate 10 is material storage tray 8, and storage tray 8 is placed On the lifting plate 12, lifting devices 11 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com