Food packing device provided with detector

A technology of food packaging and detection device, applied in the field of food packaging, can solve problems such as damage to packaging bags and inability to keep fresh food fresh, and achieve the effects of reducing oxygen partial pressure, preventing mildew deterioration and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

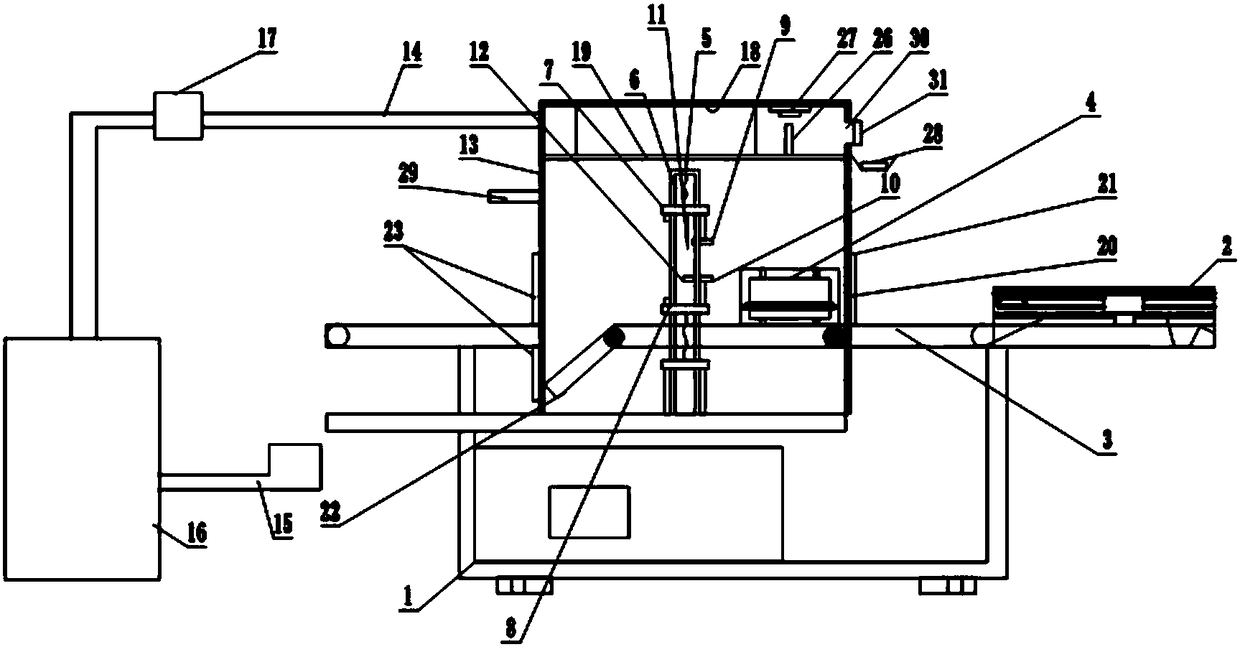

[0030] Such as figure 1 As shown, a food packaging device with a detection device includes a frame 1, and a feeding mechanism 2 and a bag feeding mechanism 3 that are sequentially installed on the frame 1 and provided with a conveyor belt, and also includes a bag sealing mechanism 4 and a sealing device 5. The sealing device 5 includes a slide rail 6, a first slide block 7 and a second slide block 8. The first slide block 7 and the second slide block 8 are slidably installed on the slide rail 6. The first slide block 7 and the second slide block The driving device that drives the first slider 7 and the second slider 8 to slide on the slide rail 6 is welded on the second slider 8, and the first thermoplastic plate 9 is installed on the first slider 7 with bolts, and the second slider On the block 8, a second thermoplastic plate 10 opposite to the first thermoplastic plate 9 is fixedly installed with bolts, and the first thermoplastic plate 9 and the second thermoplastic plate 1...

Embodiment 2

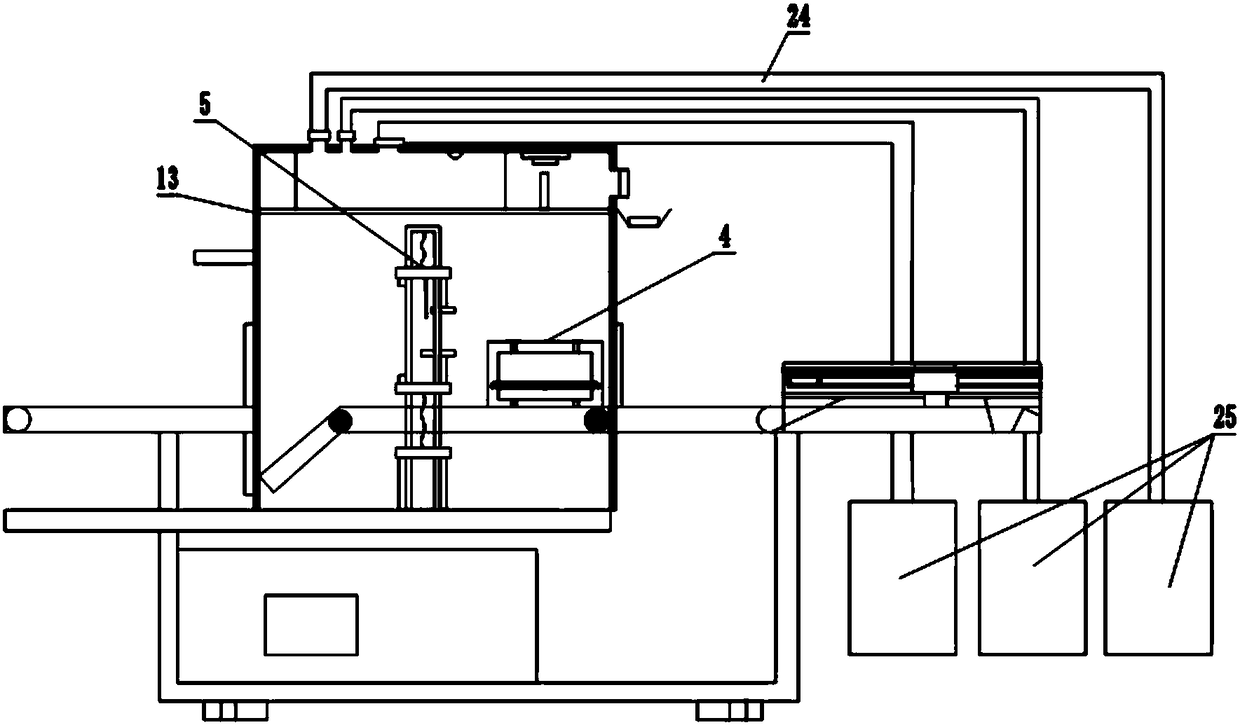

[0037] Such as figure 2 As shown, the difference between the present embodiment and the scheme described in Embodiment 1 is that the vacuum box 13 is also connected with three atmosphere regulating tanks 25 through the air intake pipe 24 equipped with an air intake pump, and the three atmosphere regulating tanks 25 are respectively equipped with oxygen, carbon dioxide and nitrogen.

[0038] After the fresh food continues to be transported into the vacuum box 13 on the conveyer belt of the bag feeding mechanism 3, start the vacuum box 13 to extract the air inside to form a vacuum packaging environment. Regulating gases such as oxygen, carbon dioxide and nitrogen are added in different proportions, and when the fresh food is transported to the bag sealing mechanism 4, the bag sealing mechanism 4 will seal the bag covered with fresh food and a certain proportion of regulating gas, and then Sealing, cutting and separation are carried out by the sealing device 5, so as to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com