Production and processing technology of waterproof coating for acrylic floor paint

A processing technology, waterproof coating technology, applied in the direction of sustainable manufacturing/processing, coating, chemical industry, etc., can solve the problems of difficult dispersion of raw materials, difficult temperature control, uneven heating, etc., to achieve sufficient internal reaction, energy saving, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

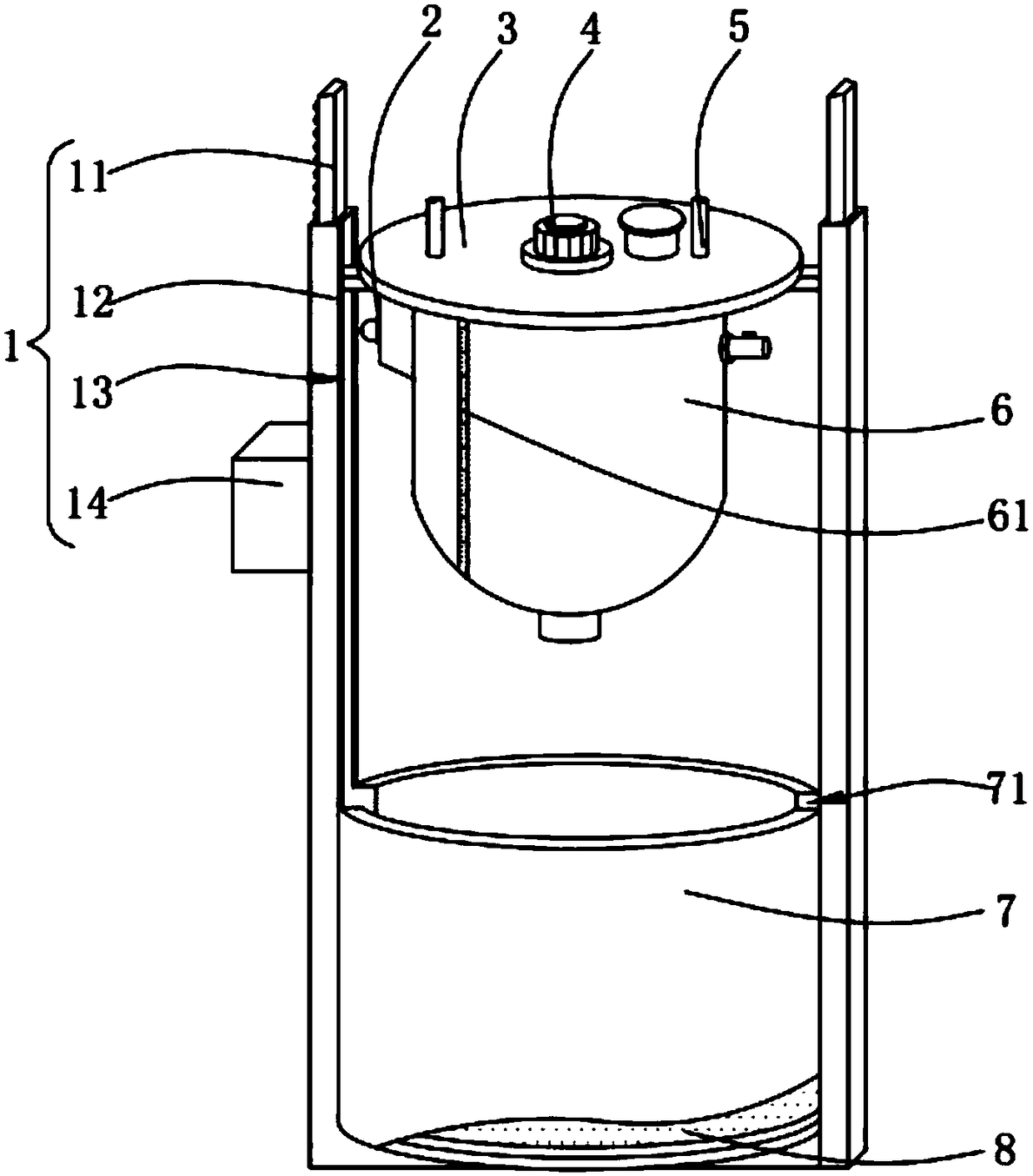

[0032] Such as figure 1 Shown, a kind of acrylic floor paint waterproof coating production process of the present invention, this production process comprises the following steps:

[0033] Step 1, weighing raw materials, weighing a certain amount of acrylate and other ingredients;

[0034] Step 2, adding the raw materials weighed in step 1 to the paint mixing equipment for mixing;

[0035] Step 3, after step 2 is completed, the mixed paint is loaded into the packaging barrel by the paint mixing equipment;

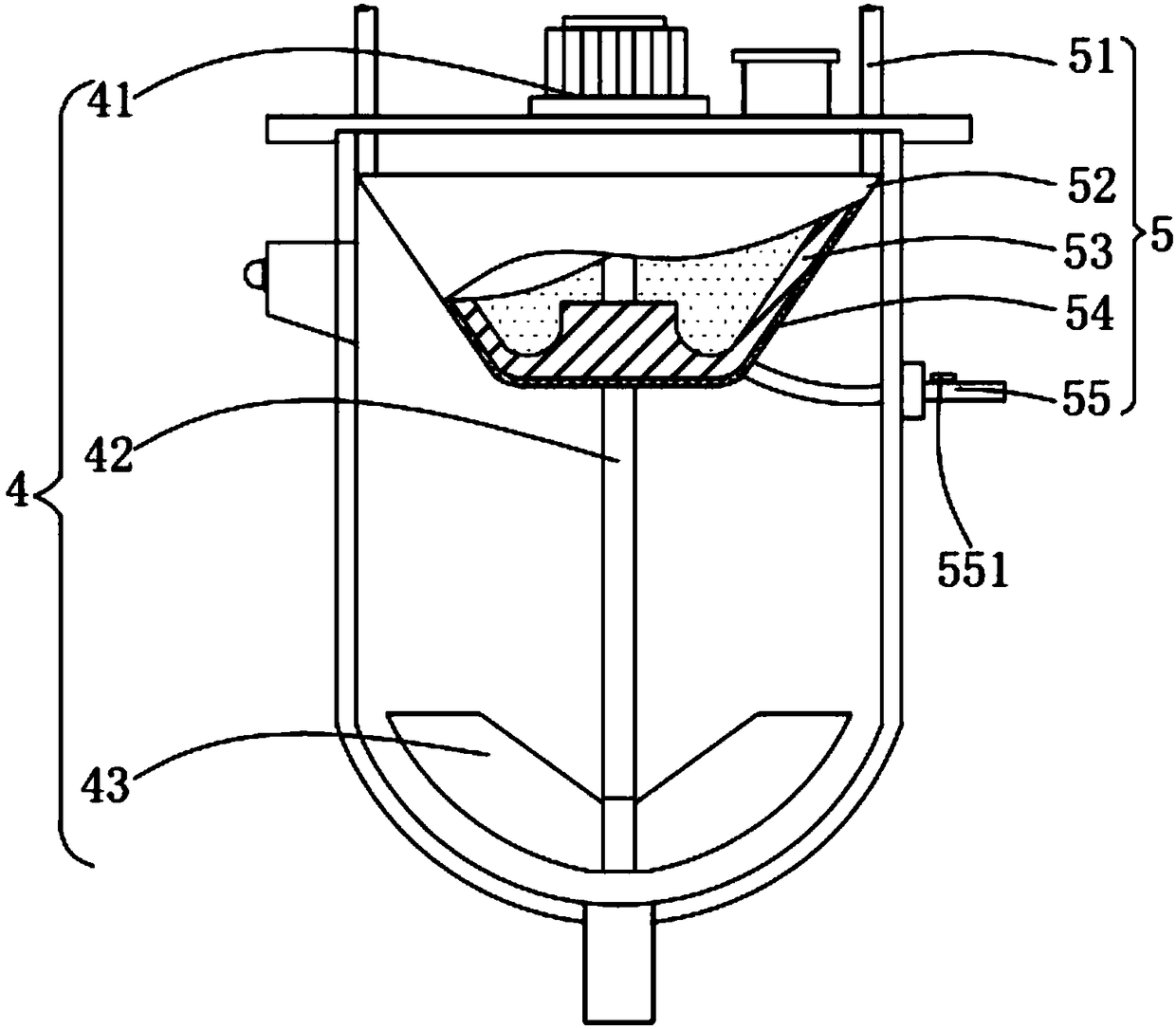

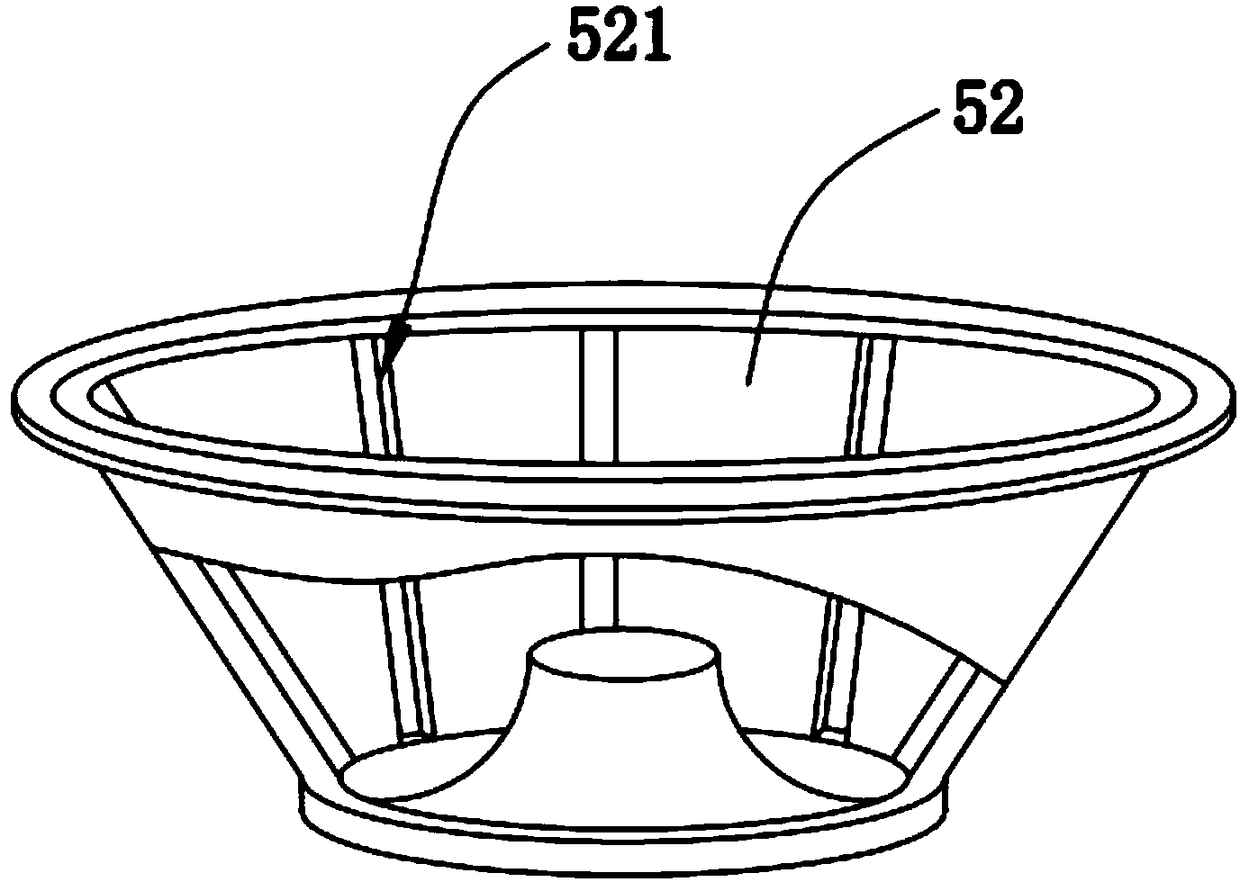

[0036] The paint mixing equipment adopted in the above-mentioned step 2 includes a lifting mechanism 1, a feeding mechanism 2, a cover plate 3, a stirring mechanism 4, a dehydration mechanism 5, a treatment cabinet 6, a water bath cabinet 7 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap