Anti-fouling automobile interior fabric and preparation method thereof

A technology for automotive interiors and fabrics, applied in the field of anti-fouling automotive interior fabrics and its preparation, can solve problems such as poor wear resistance, and achieve the effects of improving wear resistance, improving wear resistance, and excellent oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

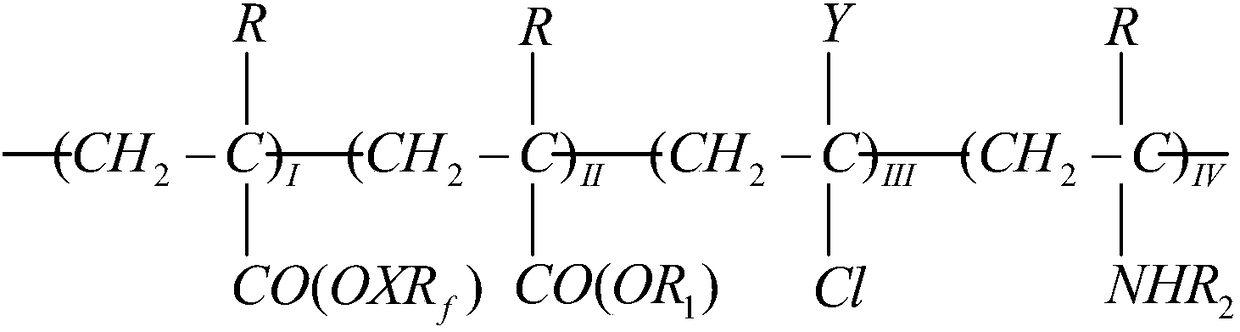

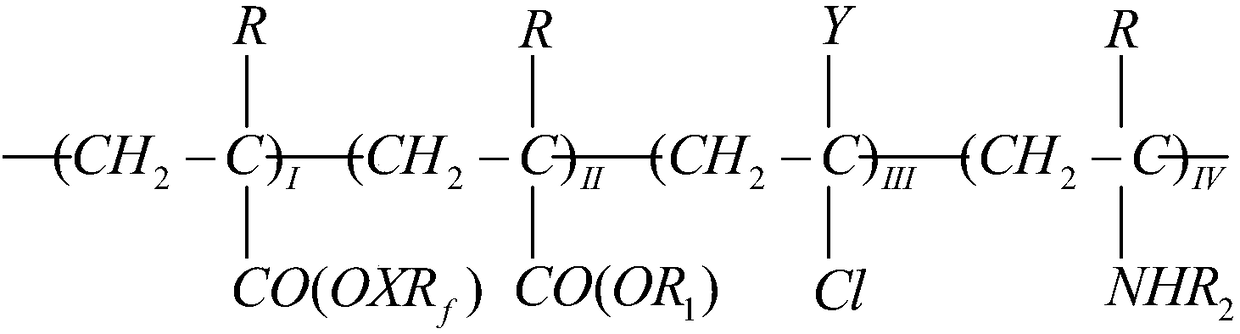

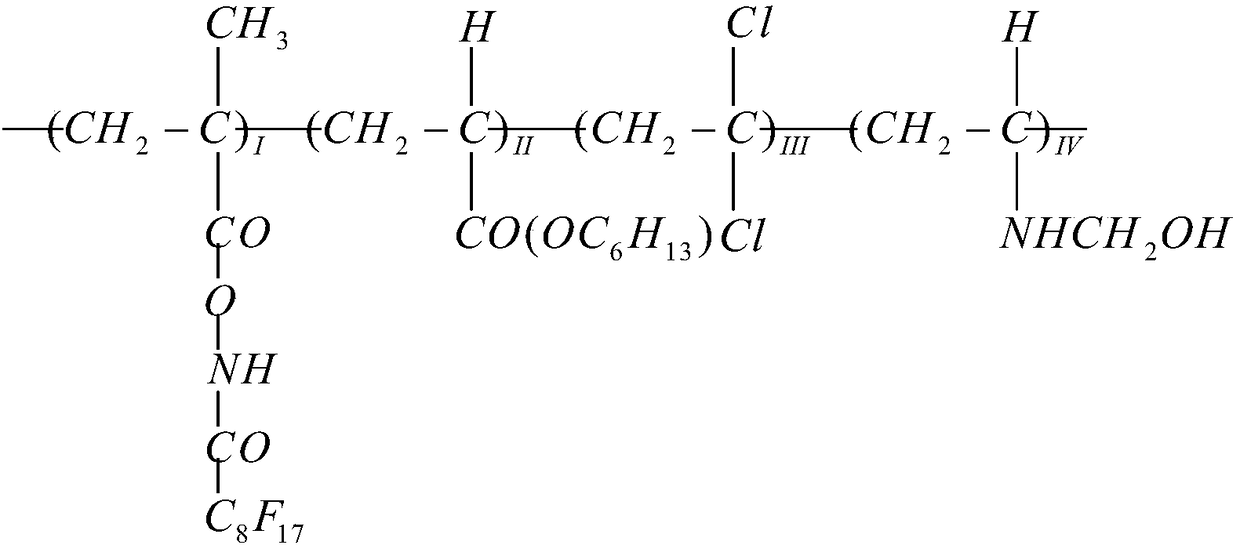

Method used

Image

Examples

preparation example Construction

[0046] First aspect, the embodiment of the present invention provides a kind of preparation method of antifouling automobile interior fabric, and this preparation method comprises:

[0047] Step 1. Mix silica nano-microspheres, fluorine-containing acrylate copolymer, aqueous isocyanate and water, and stir to obtain a finishing solution.

[0048] Step 2, immersing the automotive interior fabric in the finishing solution, and sequentially rolling, drying, and baking to obtain the antifouling automotive interior fabric.

[0049] Wherein, the mass fractions of silicon dioxide nano-microspheres, fluorine-containing acrylate copolymer, and water-based isocyanate in the finishing solution are 0.2%-1.2%, 1.5%-8%, and 0.1%-0.72%, respectively.

[0050] It should be noted that silica nanospheres are silica particles with a particle size ranging from 5 nanometers to 1000 micrometers.

[0051] It can be seen that the finishing liquid used in the preparation method of the antifouling auto...

Embodiment 1

[0114] The present embodiment provides a kind of antifouling automobile interior fabric, and its preparation method comprises:

[0115] (1) Disperse tetraethyl orthosilicate in an aqueous alcohol solution (composed of ethanol and distilled water) to obtain a first solution. Wherein, the mass fraction of ethyl orthosilicate in the first solution is 1.88%, and the mass fraction of distilled water is 2.53%. Add ammonia water with a mass percentage concentration of 22% into ethanol to obtain an alcoholic ammonia solution with a mass fraction of ammonia of 6.60%.

[0116] Add the alcoholic ammonia solution to the first solution at a rate of 20 μl / min while stirring at a rotational speed of 1000 rpm. After all the alcohol ammonia solution is added to the first solution, continue to stir at a speed of 1000 rpm for 30 minutes, then let it stand for 24 hours to obtain the second solution, centrifuge the second solution, and then dry the obtained solid particles at 100°C After 3 hours...

Embodiment 2

[0126] The present embodiment provides a kind of antifouling automobile interior fabric, and its preparation method comprises:

[0127] (1) Disperse tetraethyl orthosilicate in an aqueous alcohol solution (composed of ethanol and distilled water) to obtain a first solution. Wherein, the mass fraction of ethyl orthosilicate in the first solution is 1.90%, and the mass fraction of distilled water is 1.63%. Add ammonia water with a mass percentage concentration of 25% into ethanol to obtain an alcoholic ammonia solution with a mass fraction of ammonia of 5.55%.

[0128] Add the alcoholic ammonia solution to the first solution at a rate of 25 μl / min while stirring at a rate of 800 rpm. After all the alcohol ammonia solution is added to the first solution, continue to stir at a speed of 800 rpm for 60 minutes, then let it stand for 48 hours to obtain the second solution, centrifuge the second solution, and then dry the obtained solid particles at 120°C After 1.5 h, silica nanosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com