Valley electricity heat-storage warmer and manufacturing method thereof

A heater and heat storage technology, applied in chemical instruments and methods, heating methods, electric heating systems, etc., can solve the problem of high electricity costs for electric heaters, and achieve the effect of a simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

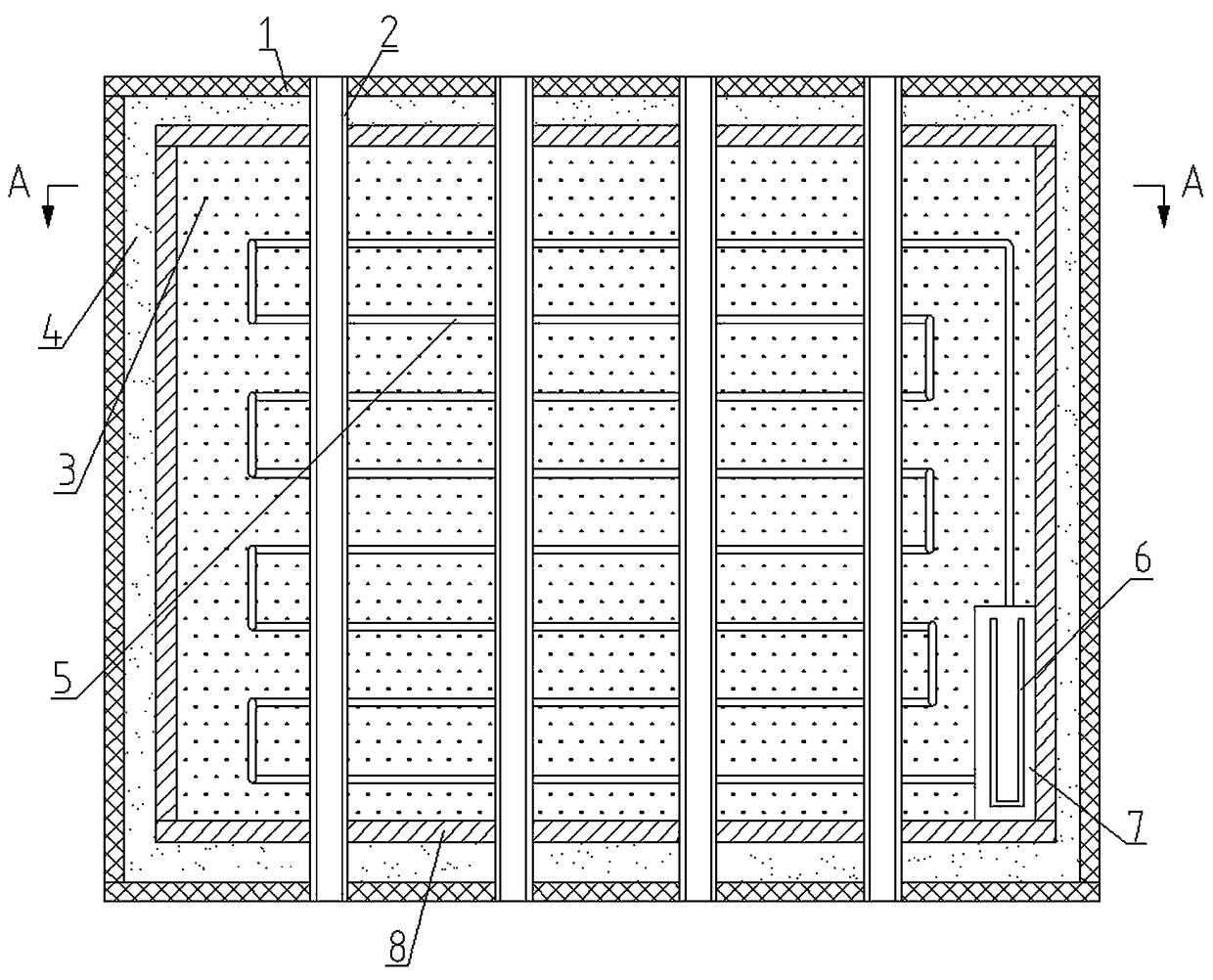

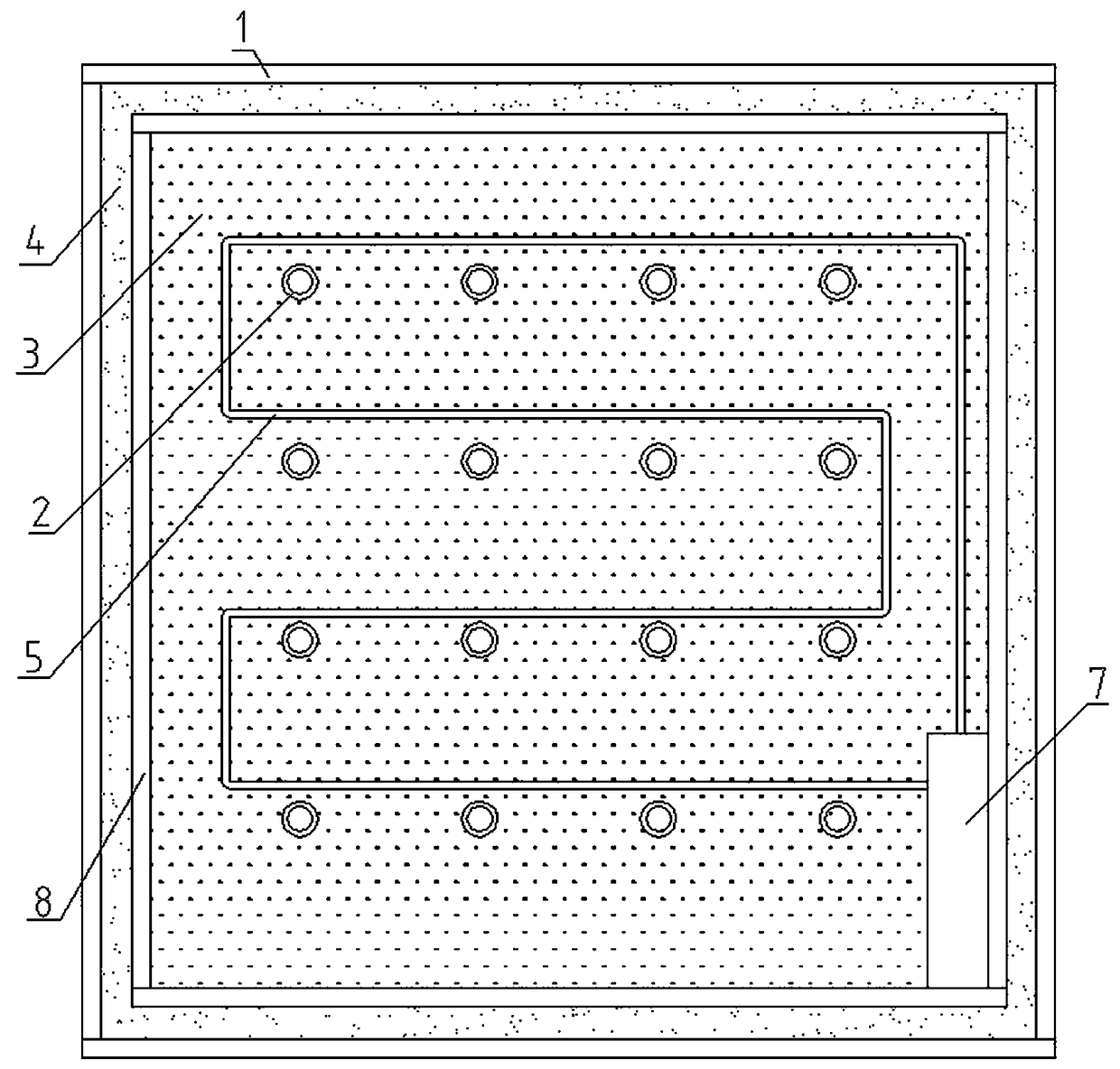

[0022] Describe the present invention below in conjunction with accompanying drawing and embodiment:

[0023] A kind of valley electricity thermal storage heater, see attached figure 1 And attached figure 2 , in the figure, the shell 1, the cooling pipe 2, the composite phase change material 3, the foam insulation material 4, the oil guide pipe 5, the electric heating pipe 6, the fuel tank 7, and the liner 8.

[0024] In this embodiment, several cooling pipes 2 are evenly distributed on the inner tank 8, the cooling tubes 2 are made of aluminum tubes, the upper ends of the cooling tubes 2 pass through the upper connecting plate of the inner tank 8, and the lower ends of the cooling tubes 2 pass through the inner tank 8 The lower connecting plate, the two ends of the radiating pipe 2 are non-closed for gas circulation; the space between adjacent radiating pipes 2 is arranged with an oil guide pipe 6, the oil guide pipe 6 is connected with the fuel tank 7, and the rest of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com