Full-efficiency combined air source heat pump system

An air source heat pump, combined technology, applied in heating systems, hot water central heating systems, energy-saving heating/cooling, etc. Cold source waste and other problems, to avoid energy efficiency decay or crash, reduce energy waste, and improve energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail without limitation in conjunction with the accompanying drawings and examples below.

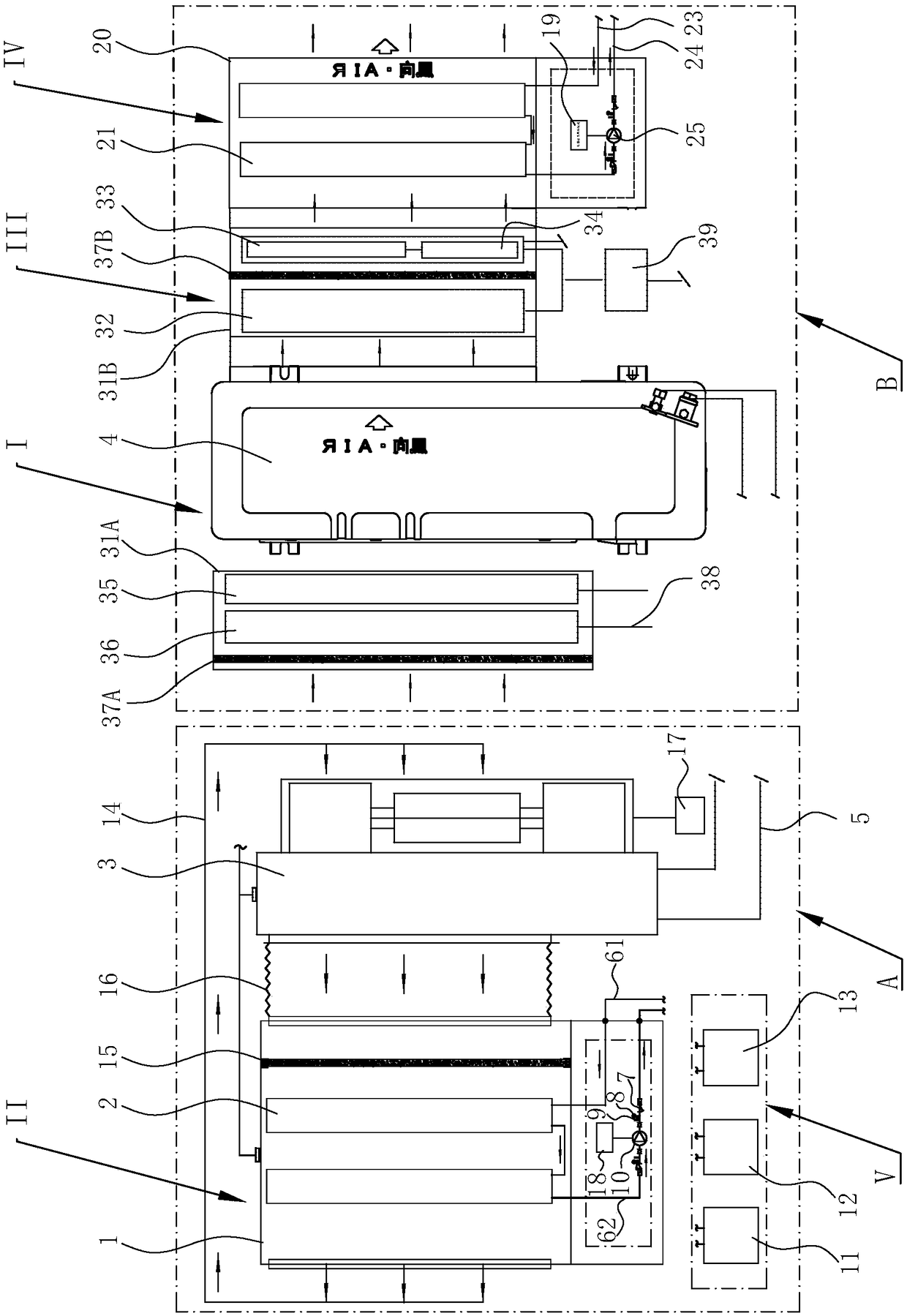

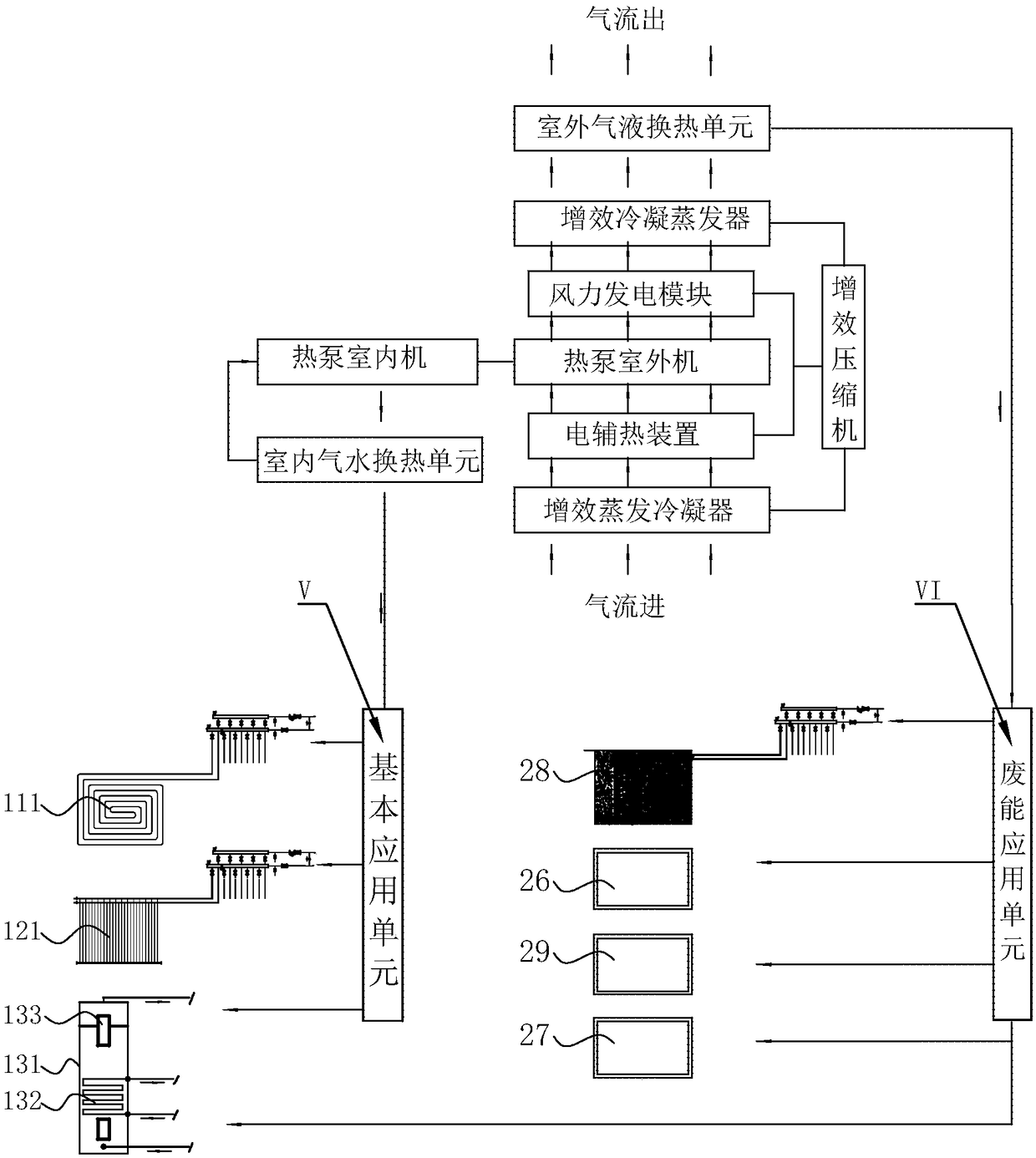

[0039] Such as figure 1 and figure 2 Commonly shown, the full-efficiency combined air source heat pump system of the present invention is divided into an indoor part A of the air source heat pump system and an outdoor part B of the air source heat pump system, including an air source heat pump unit I, an indoor air-water heat exchange unit II, an outdoor exhaust Wind efficiency unit III, outdoor gas-liquid heat exchange unit IV.

[0040] The air source heat pump unit 1 includes a heat pump controller 17 and a heat pump indoor unit 3 and a heat pump outdoor unit 4 connected through a refrigerant pipeline 5; the known heat pump indoor units have many different options, and can be frequency conversion multi-unit indoor units , or an indoor unit of an air-cooled modular unit, or a domestic and commercial one-to-one unit indoor u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com