A method of drying batteries

A drying method and cell technology, applied in drying chambers/containers, drying solid materials, local agitation dryers, etc., can solve the problems of slow heat transfer, limit water content not reaching the target value, large escape resistance, etc., to achieve Increased speed, effect of fast and efficient drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

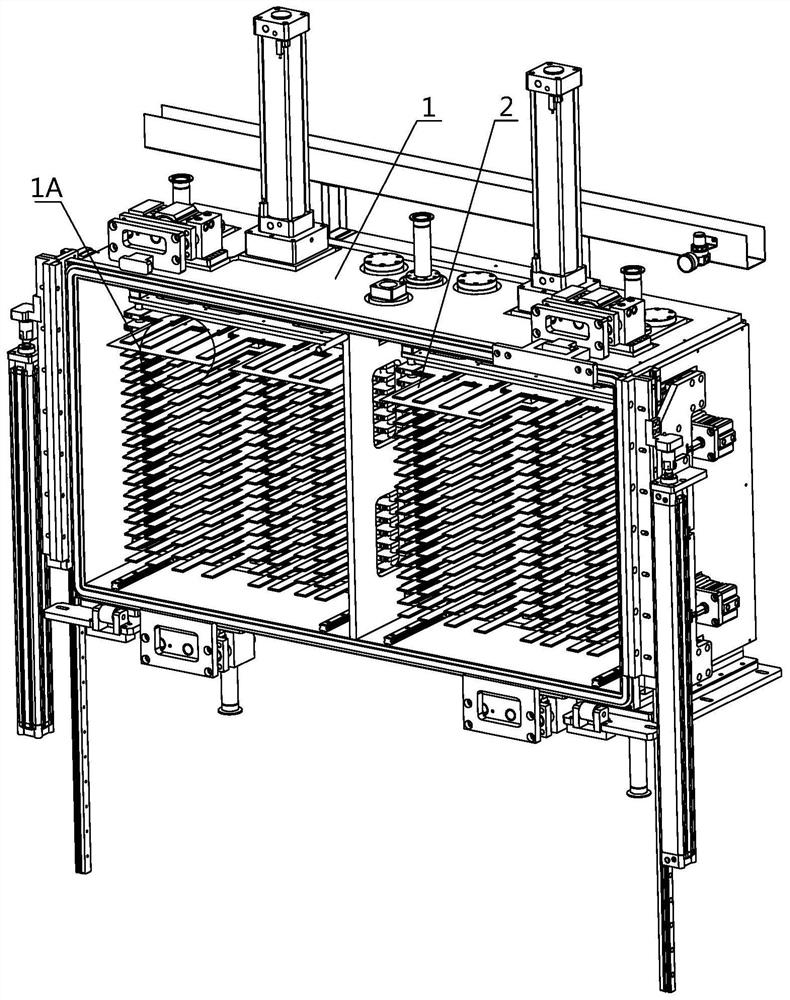

[0033] Such as Figure 1-3 As shown, in the cell drying method described in Embodiment 1 of the present invention, the purpose of implementing the technical means is to solve the problem of traditional battery electric heating due to the slow heat transfer speed in vacuum due to the traditional equipment adopting radiation heating. Cell drying equipment generally has the problem of low drying efficiency, so as to ensure that each cell can achieve an ideal dryness and avoid adverse effects on the cell drying process. Therefore, the technical solution implemented in the present invention is based on the battery production equipment The manipulator performs the drying process on the battery cells after the cooling treatment, including the following steps:

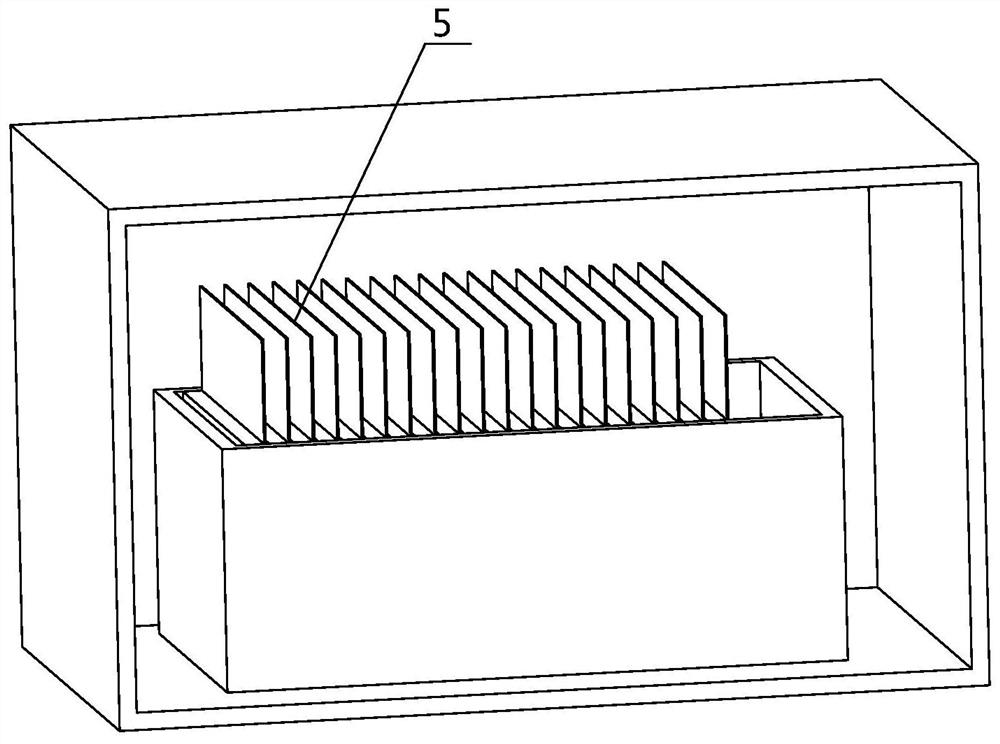

[0034] First of all, the structure of the drying box is set, and a closed vertical drying box 1 with a vacuum mechanism is selected, and the inside of the box is vertically divided into several drying chambers through a partit...

Embodiment 2

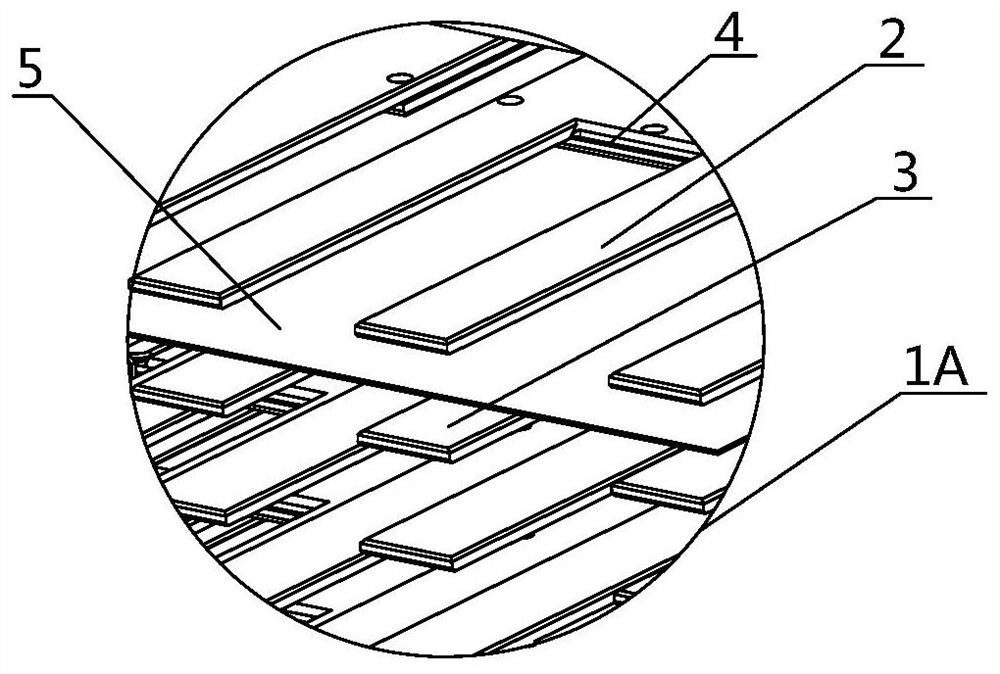

[0047] Such as Figure 1-3 As shown, the battery drying equipment described in the second embodiment of the present invention is a modification based on the first embodiment. It has a closed vertical drying box, and the implemented vertical drying box 1 A number of contact heating units arranged in several rows and columns, each contact heating unit is composed of an upper platen 2 and a lower platen 3, and a contact heating station is formed between the two platens of each group of contact heating units;

[0048] Correspondingly, the implemented battery cell drying equipment also includes a heating wire 4, which is arranged between the upper platen 2 and the lower platen 3 of each contact heating unit and seals the battery cell 5 of the contact heating station. Dry under pressure.

[0049] According to different processing requirements, a fixing component for fixing the electric core can also be provided on the contact heating station.

[0050] Other technical means of Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com