Visual test device for penetration grouting of broken coal and rock mass and test method of visual test device

A technology for crushing coal and rock mass and test equipment, which is applied in measurement equipment, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of inability to observe the slurry flow form and diffusion process in real time, uneven slurry diffusion, Easy to block pulp and other problems, to achieve the effect of simple production, low cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

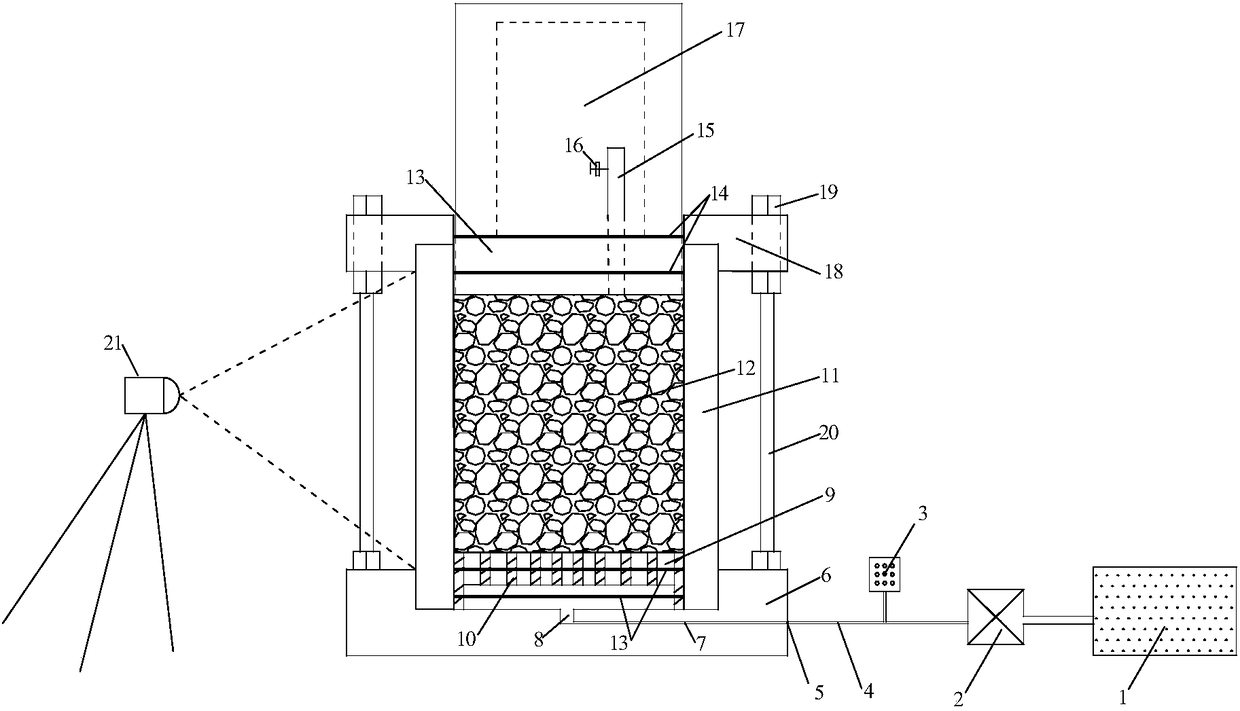

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0025] In this embodiment, the base, the permeable plate, the sealing pressure head and the loading hollow pressure head are all made of high-strength steel (the material specification is Q355-460). The diameter of the base is 300-500mm, the thickness (height) is 20-50mm; the fully transparent grouting barrel is made of super armored polycarbonate, its inner diameter is 100-200mm, the wall thickness is 10-30mm, and the height is 200-300mm; The bolt strength grade is 8.8~10.9, the bolt hole diameter is 20~26mm; the annular notch width of the base is 10~30mm, and the depth is 10~20mm; the diameter of the base grouting hole is 10~20mm; the diameter of the grout plate is 100~200mm , The thickness (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com