Method for alleviating freezing damage to pear fruitlets

A technology for young pear fruit and freezing damage, applied in the field of antifreeze agent for young pear fruit, can solve the problem of less freezing damage of young pear fruit, and achieve the effect of reducing unexpected economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

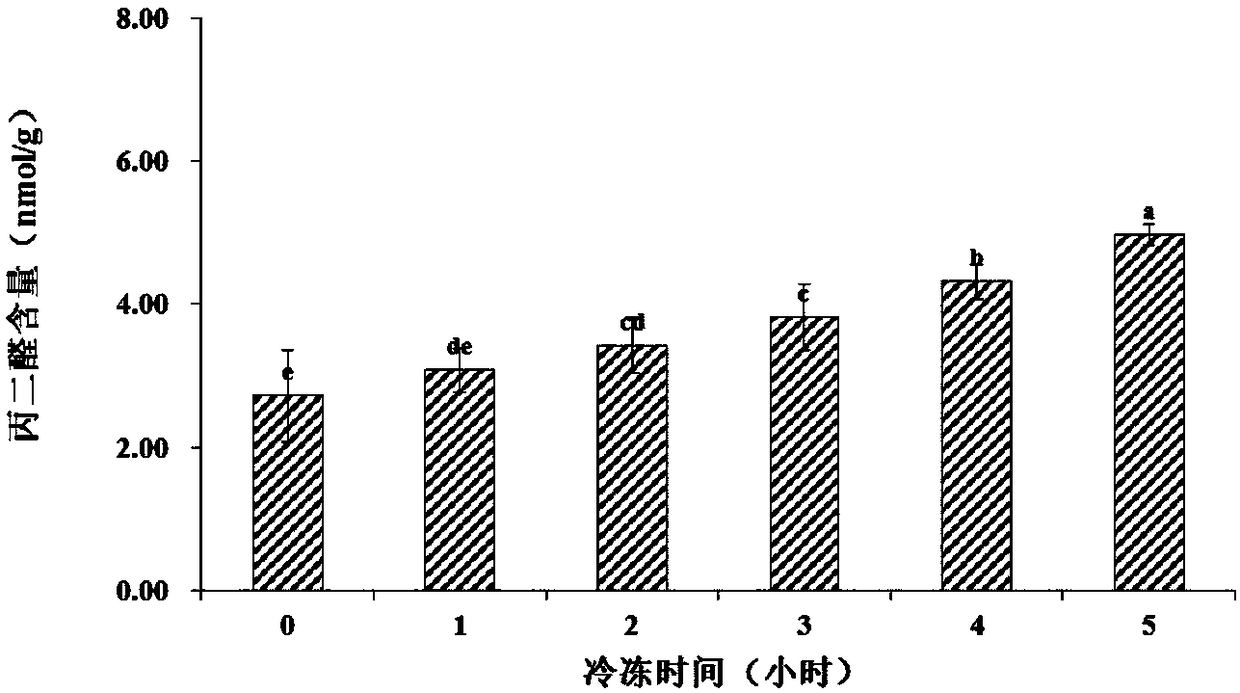

[0032] Embodiment one: the impact of frost time on young fruit membrane lipid peroxidation

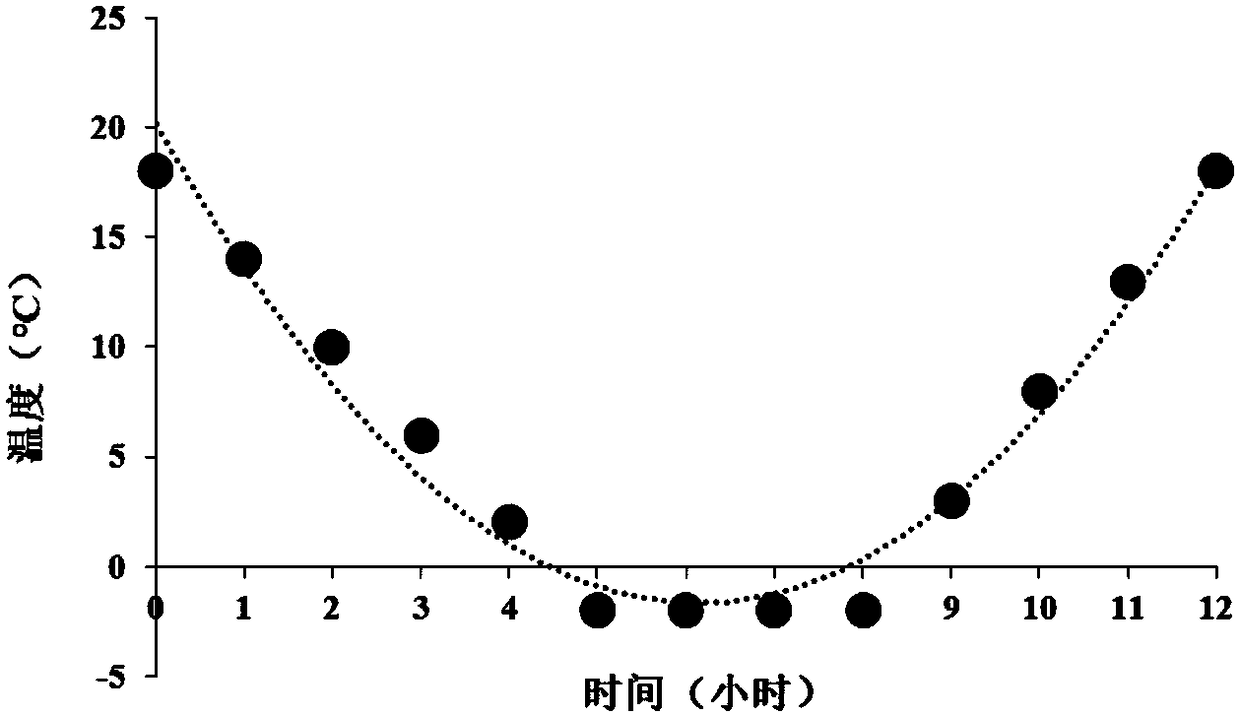

[0033] (1) Experimental process

[0034] After 10 days of pollination of "Cuiyu" pear young fruit, the artificial climate chamber was used to simulate the natural frost process: the temperature was lowered from 18°C at a rate of 4°C / hour, and maintained at -2°C at 0, 1, 2, 3, 4 and 5 After one hour, young fruits with the same size and different positions were taken at different time points to measure the content of malondialdehyde.

[0035] (2) Experimental results

[0036] Flower and fruit drop caused by frost is mostly caused by the destruction of flower and young fruit cell membranes, and active oxygen free radicals play an important role in this process. The change of malondialdehyde content in young fruit under low temperature stress can directly reflect the degree of oxidation of cell membrane lipid and the permeability of cell membrane. At the beginning of freezing, the con...

Embodiment 2

[0038] Embodiment two: the screening of antifreeze

[0039] (1) Experimental process

[0040] Spray 500mL of 10 kinds of chemical antifreeze on the young fruit 10 days after pollination, take the water treatment as the control, and put it into the artificial climate chamber for low temperature treatment after 2 days. The young fruits with the same size and different positions were taken to determine the malondialdehyde content.

[0041] Determination of malondialdehyde content: Thiobarbituric acid colorimetric method. Take 0.50g young fruit sample, add 5mL of 5% (g / 100ml) trichloroacetic acid, and centrifuge the resulting slurry at 3000r / min for 10min after grinding. Take 2ml of the supernatant, add 2mL of 0.67% (g / 100ml) thiobarbituric acid, mix it in a water bath at 100°C for 30min, cool and then centrifuge. The absorbance values at 450nm, 532nm and 600nm were measured respectively.

[0042] The 10 kinds of chemical antifreeze agents are Bibo PBO, Tianda 2116, prohexad...

Embodiment 3

[0050] Example 3: Verification and combination of the screened antifreeze agents

[0051] (1) Experimental process

[0052] Spray 500mL of the antifreeze selected in Example 2 individually / combinedly. The combined antifreeze is prepared from 6-benzylaminoadenine and salicylic acid, the concentration of 6-benzylaminoadenine in the aqueous solution is 0.50mg / L, and the concentration of salicylic acid is 3.62mmol / L. Taking the water treatment as the control, put it into the artificial climate chamber for low temperature treatment after 2 days. The young fruits with the same size and different positions were taken to determine the malondialdehyde content.

[0053] (2) Experimental results

[0054] The study found that 6-benzylaminoadenine, salicylic acid and combined antifreeze can significantly inhibit the freezing damage of young fruit; among them, the combination of antifreeze has a better effect (attached Figure 5 ). After freezing treatment, the malondialdehyde content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com