Resin-permeated silicate composite material and preparation and application thereof

A composite material, resin infiltration technology, applied in the direction of dental preparations, dental prostheses, compression mold cups, etc., can solve the problem of transparency to be improved, and achieve the effect of facilitating large-scale production, simplifying the preparation process, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

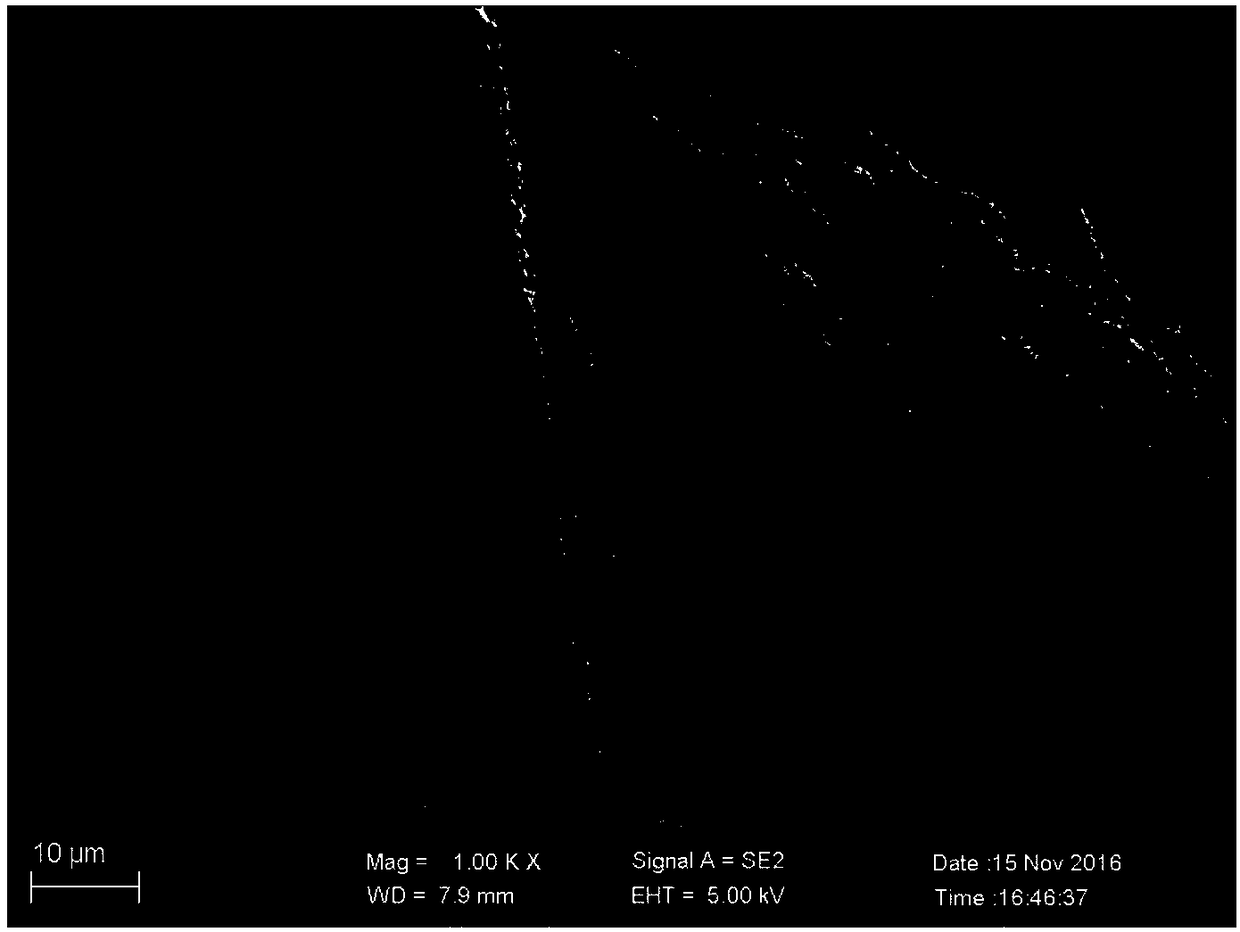

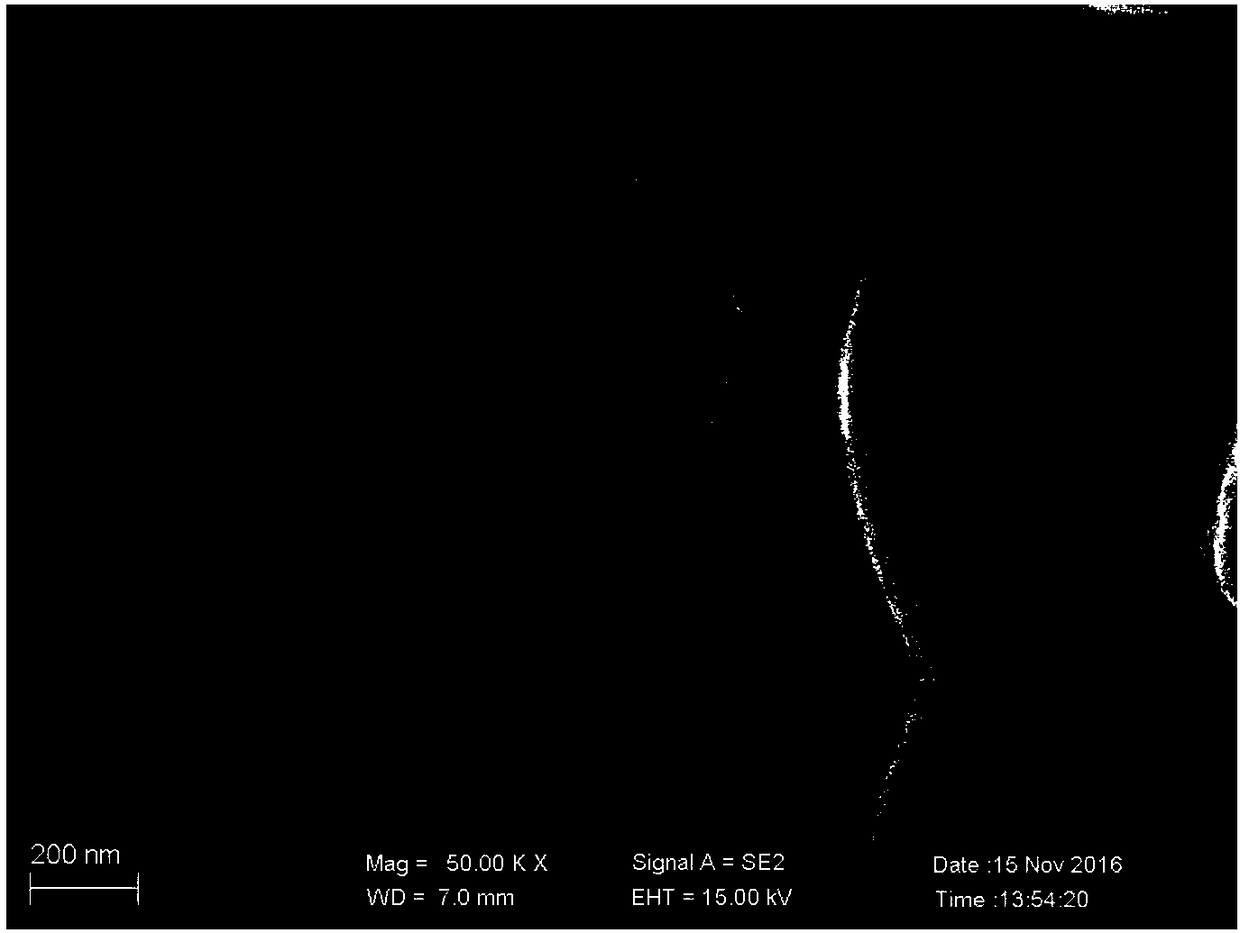

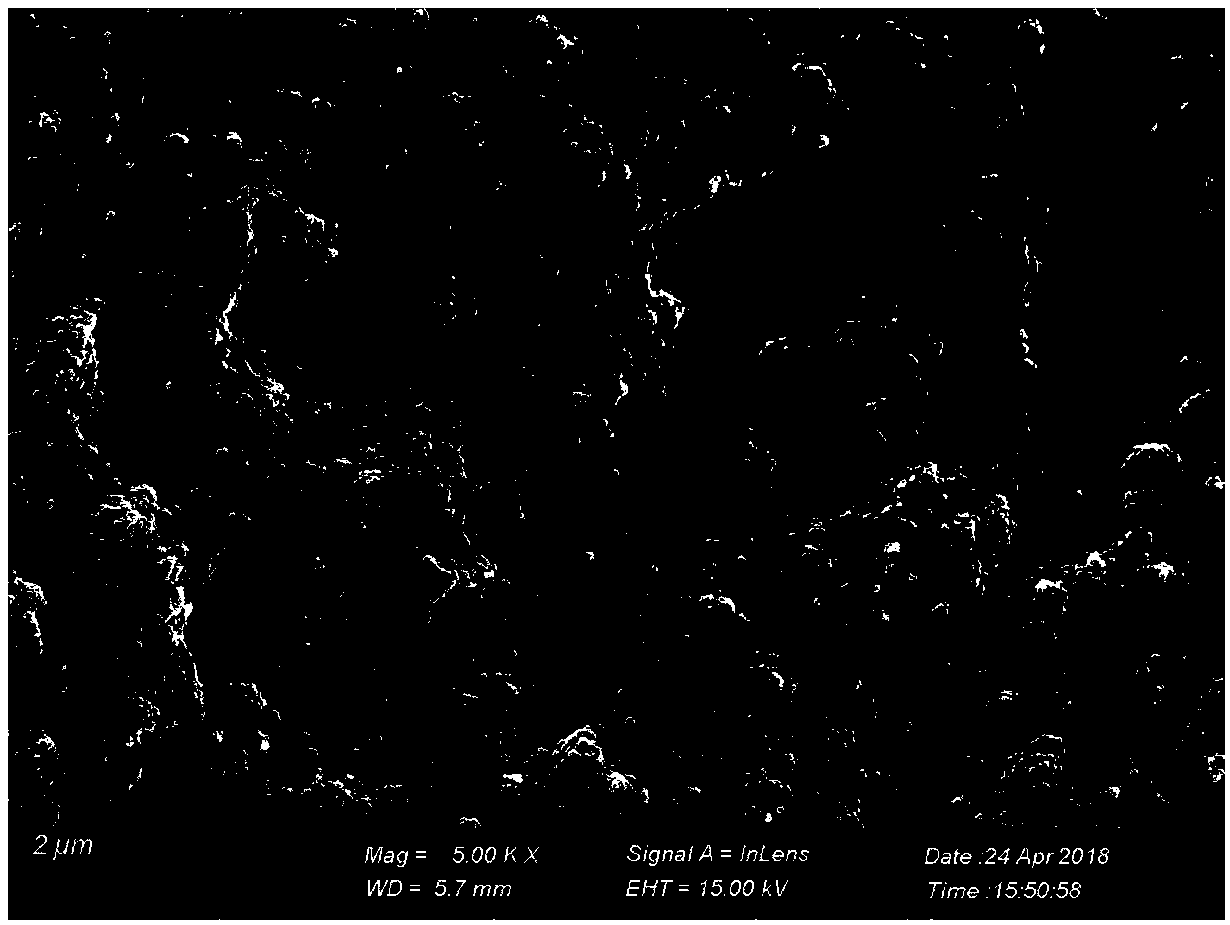

[0056] Weigh 20g of sodium aluminum silicate, mix it with deionized water, and stir for 2h. Inject the mixed solid-liquid mixture into a gypsum mold for grouting molding, let it stand for 2 hours, remove part of the water, take out the molded green body, and let it dry naturally to obtain a dried green body. The dried green body was sintered at a temperature of 700 °C, the heating rate was 5 °C / min, and the holding time was 1 min to prepare a porous ceramic block (its microstructure is as follows: figure 1 and figure 2 shown). Mix bisphenol A diglycidyl methacrylate with triethylene glycol dimethacrylate in a mass ratio of 1:1, stir for 2 hours, and mix 2wt% (based on bisphenol A diglycidyl methacrylate The total mass of ester and tetraethylene glycol dimethacrylate) of benzoyl peroxide was added to the above mixture and continued to stir for 2h. Inject the resin mixture into the mold, place the above-mentioned porous ceramic block (i.e. porous sodium aluminum silicate blo...

Embodiment 2

[0060] Weigh 20g of sodium aluminum silicate, mix it with deionized water, and stir for 2h. Inject the mixed solid-liquid mixture into a gypsum mold for grouting molding, let it stand for 2 hours, remove part of the water, take out the molded green body, and let it dry naturally to obtain a dried green body. The dried green body was sintered at a temperature of 750° C., the heating rate was 5° C. / min, and the holding time was 1 min to prepare a porous ceramic block. Mix bisphenol A diglycidyl methacrylate with triethylene glycol dimethacrylate in a mass ratio of 1:1, stir for 2 hours, and mix 2wt% (based on bisphenol A diglycidyl methacrylate The total mass of ester and tetraethylene glycol dimethacrylate) of benzoyl peroxide was added to the above mixture and continued to stir for 2h. Inject the resin mixture into the mold, place the above-mentioned porous ceramic block (i.e. porous sodium aluminum silicate block) in it, place it in a vacuum environment, use vacuum capillary...

Embodiment 3

[0064] Weigh 20g of sodium aluminum silicate, mix it with deionized water, and stir for 2h. Inject the mixed solid-liquid mixture into a gypsum mold for grouting molding, let it stand for 2 hours, remove part of the water, take out the molded green body, and let it dry naturally to obtain a dried green body. The dried green body was sintered at a temperature of 800° C., the heating rate was 5° C. / min, and the holding time was 1 min to prepare a porous ceramic block. Mix bisphenol A diglycidyl methacrylate with triethylene glycol dimethacrylate in a mass ratio of 1:1, stir for 2 hours, and mix 2wt% (based on bisphenol A diglycidyl methacrylate The total mass of ester and tetraethylene glycol dimethacrylate) of benzoyl peroxide was added to the above mixture and continued to stir for 2h. Inject the resin mixture into the mold, place the above-mentioned porous ceramic block (i.e. porous sodium aluminum silicate block) in it, place it in a vacuum environment, use vacuum capillary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com