Preparation method for Sn based composite solder sheets

A composite welding and sheet technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of poor high-temperature service performance, low joint strength, low efficiency, etc., to ensure fluidity, improve Effects of strength and high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

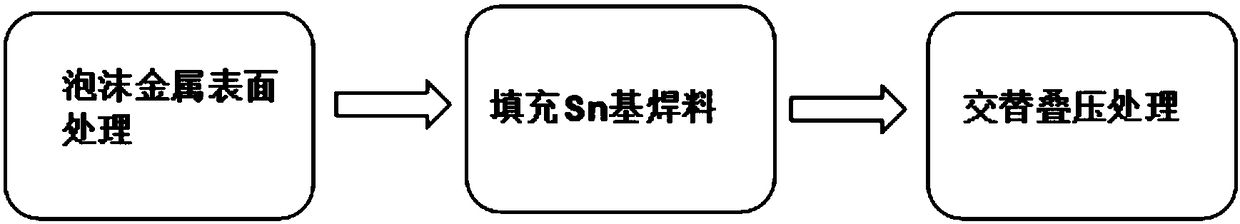

Method used

Image

Examples

Embodiment 1

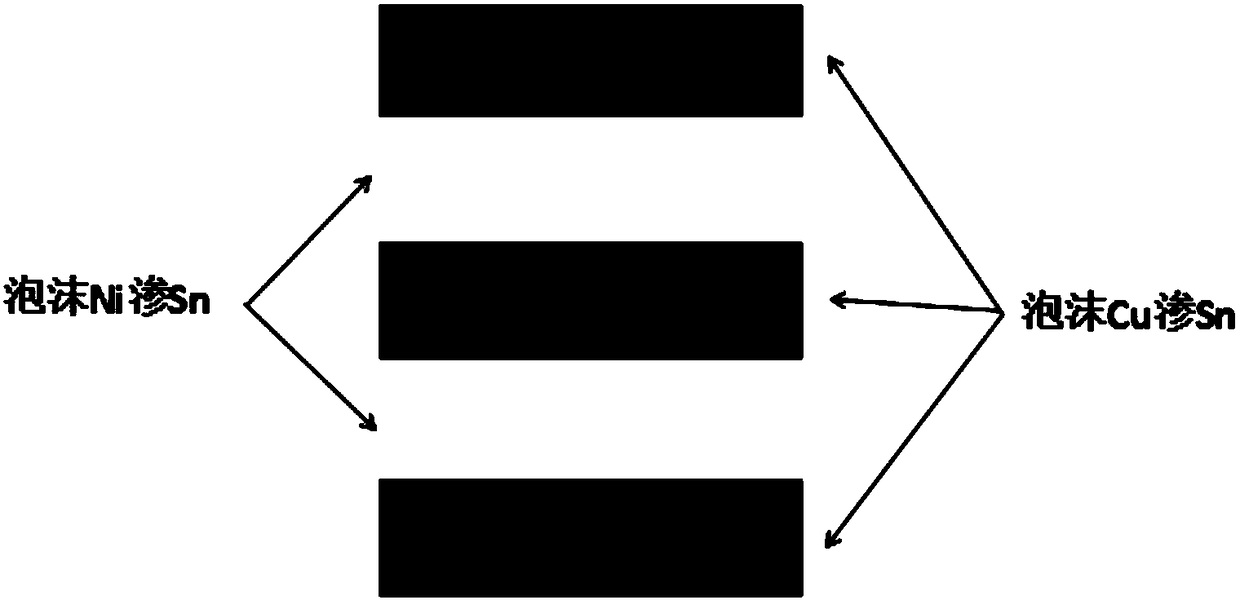

[0026] The metal foam matrix selected in this embodiment is copper foam and nickel foam with a porosity of 98%, and the solder is pure Sn. The specific operation steps are as follows:

[0027] After the copper foam and nickel foam with a size of 10mm×10mmx0.5mm are degreased and decontaminated, they are cleaned with ultrasonic cleaning and deionized water for 5 minutes each; the treated foamed copper is immersed in molten pure tin, and the temperature of the molten tin is 260°C for 10s, the copper foam reinforced tin-based composite solder sheet was obtained; similarly, the surface-treated foamed nickel metal was immersed in molten tin, the temperature of the molten tin was 260°C, and the time of immersion in the molten tin was 15s. Nickel Foam Reinforced Tin-Based Composite Solder Sheet. Select 3 pieces of Sn-based solder sheets reinforced with copper foam and 2 pieces of Sn-based composite solder sheets reinforced with nickel foam with a relatively uniform surface, stack the...

Embodiment 2

[0030] The metal foam matrix selected in this embodiment is copper foam and nickel foam with a porosity of 60%, and the solder is pure Sn. The specific operation steps are as follows:

[0031] After the copper foam and nickel foam with a size of 10mm×10mmx0.5mm are degreased and decontaminated, they are cleaned with ultrasonic cleaning and deionized water for 5 minutes each; the treated foamed copper is immersed in molten pure tin, and the temperature of the molten tin is 260°C for 10s, the copper foam reinforced tin-based composite solder sheet was obtained; similarly, the surface-treated foamed nickel metal was immersed in molten tin, the temperature of the molten tin was 260°C, and the time of immersion in the molten tin was 15s. Nickel Foam Reinforced Tin-Based Composite Solder Sheet. Select 3 pieces of Sn-based solder sheets reinforced with copper foam and 2 pieces of Sn-based composite solder sheets reinforced with nickel foam with a relatively uniform surface, stack the...

Embodiment 3

[0034] The metal foam matrix selected in this embodiment is copper foam and nickel foam with a porosity of 98%, and the solder is a Sn-Ag alloy. The specific operation steps are as follows:

[0035] After the copper foam and nickel foam with a size of 10mm×10mmx0.5mm are degreased and decontaminated, they are cleaned with ultrasonic cleaning and deionized water for 5 minutes each; the treated foamed copper is immersed in molten pure tin, and the temperature of the molten tin is 260°C for 10s, the copper foam reinforced tin-based composite solder sheet was obtained; similarly, the surface-treated foamed nickel metal was immersed in molten tin, the temperature of the molten tin was 260°C, and the time of immersion in the molten tin was 15s. Nickel Foam Reinforced Tin-Based Composite Solder Sheet. Select 3 pieces of Sn-based solder sheets reinforced with copper foam and 2 pieces of Sn-based composite solder sheets reinforced with nickel foam with a relatively uniform surface, sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com