Sandwich structure production equipment and technology

A technology of production equipment and sandwich structure, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of increased workload of operators, difficulty in maintaining corrugated shape, unfavorable large-scale use, etc., to achieve The effect of reducing working hours, reducing usage costs, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

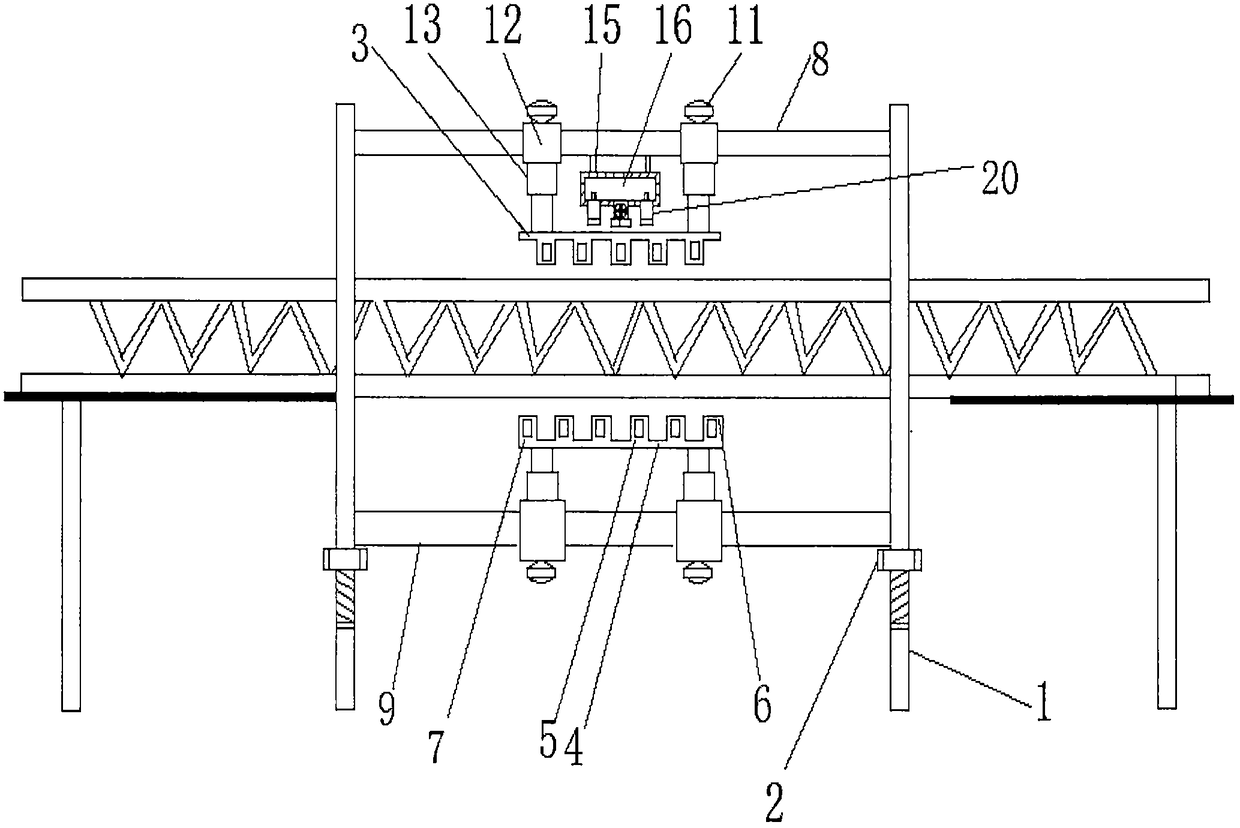

[0039] see Figure 1-5 , the present invention provides a technical solution:

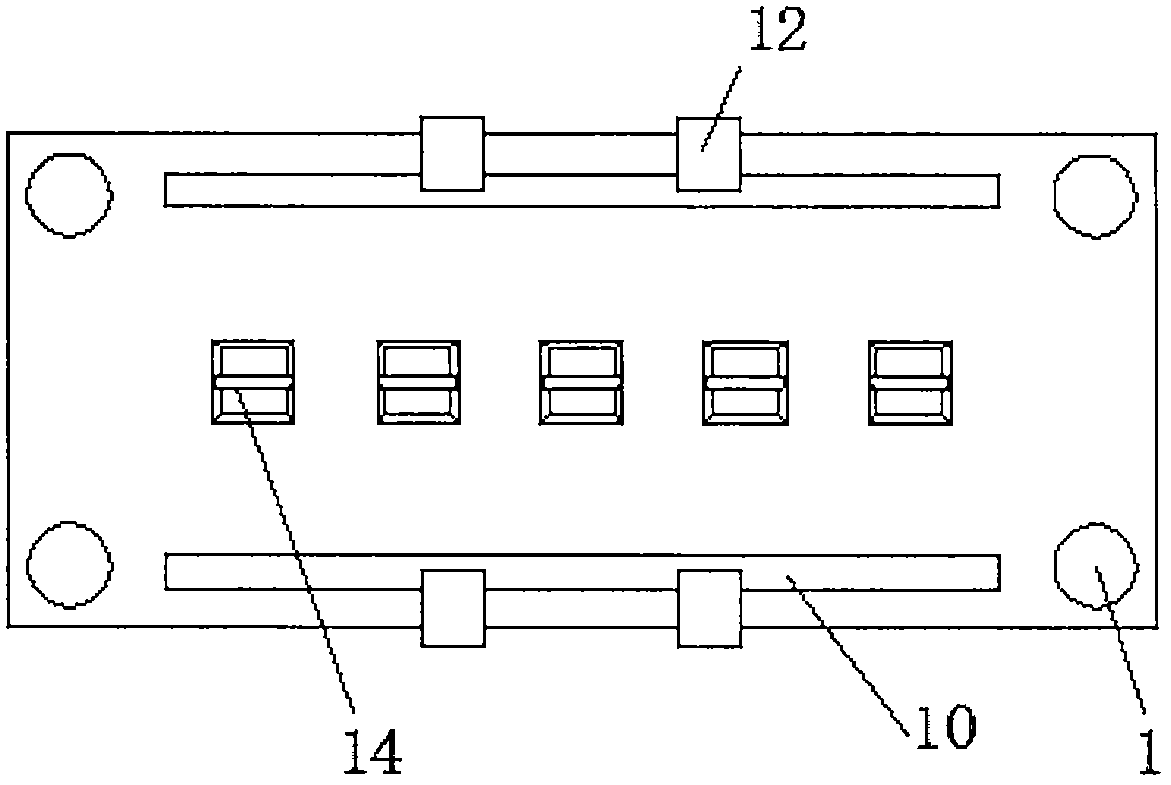

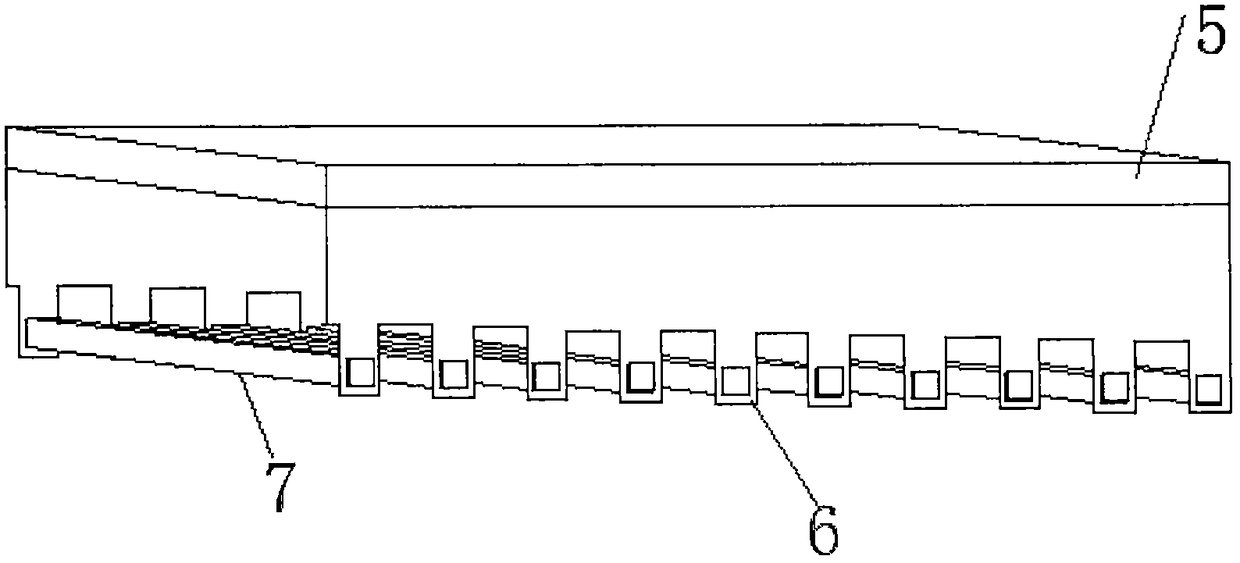

[0040]A sandwich structure production equipment, including a support frame, a pressure plate, a limit adjustment device, and a pressurized movement device. The support frame is composed of an upper support plate 8, a lower support plate 9 and four support columns 1 that run through the upper and lower support plates. , the pressure plate is U-shaped, the pressure plate includes an upper pressure plate 3 and a lower pressure plate 4, the limit adjustment device includes a slider 12 and a fixing screw 11, the pressure plate is slidably connected with the slideway 10 on the support plate through the slider 12, and through The fixed screw 11 limits the position of the slider 12, and the limit adjustment device synchronously adjusts the horizontal position of the upper platen 3 and the lower platen 4. The pressurizing movement device 13 is an oil motor, which is arranged between the slider 12 and the pl...

Embodiment 2

[0044] A sandwich structure production equipment, including a support frame, a pressure plate, a limit adjustment device, and a pressurized movement device. The support frame is composed of an upper support plate 8, a lower support plate 9 and four support columns 1 that run through the upper and lower support plates. , the pressure plate is U-shaped, the pressure plate includes an upper pressure plate 3 and a lower pressure plate 4, the limit adjustment device includes a slider 12 and a fixing screw 11, the pressure plate is slidably connected with the slideway 10 on the support plate through the slider 12, and through The fixed screw 11 limits the position of the slider 12, and the limit adjustment device synchronously adjusts the horizontal position of the upper pressing plate 3 and the lower pressing plate 4. The pressurizing movement device 13 is a cylinder, which is arranged between the slider 12 and the pressing plate to control the vertical position of the pressing plate...

Embodiment 3

[0049] The present invention also provides the production process of the above glass fiber PP composite material corrugated board sandwich panel, the core material is a prepared glass fiber PP composite material corrugated board, the face plate is a glass fiber PP composite material laminated board, and the corrugated core material is based on the core The different materials of the material can be prepared in advance into a corrugated core material or can be directly pressed by the equipment of the present invention, which specifically includes the following steps:

[0050] (1) Place the glass fiber PP composite material laminated board up and down respectively on the prepared glass fiber PP composite material corrugated board, and place the three-layer material on the lower support plate;

[0051] (2) Adjust the position of the upper and lower pressing plates through the limit adjustment device, so that the pressing rod of the upper pressing plate is at the wave trough positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com