Method for producing Ni-Mo/ZrO2 three-element functionally gradient material through dual-pulse electrodeposition

A gradient functional material, electrodeposition technology, applied in the direction of electrolytic coating, electrolytic process, electrolytic components, etc., can solve harsh problems and achieve the effect of excellent performance, good corrosion resistance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

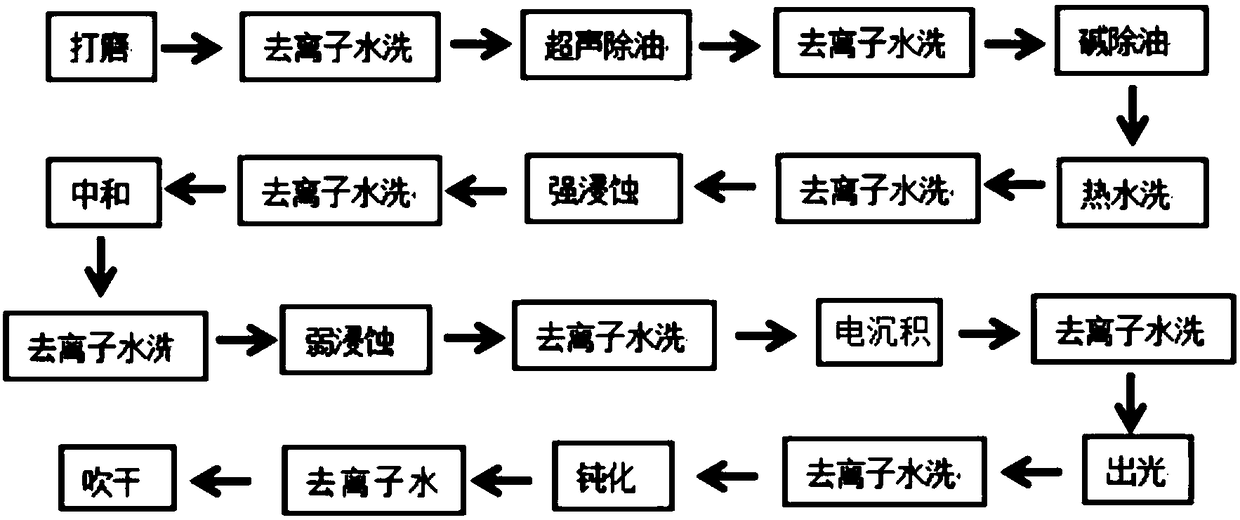

[0039] Embodiments of the present invention provide a double-pulse electrodeposited Ni-Mo / ZrO 2 A method for ternary graded functional materials.

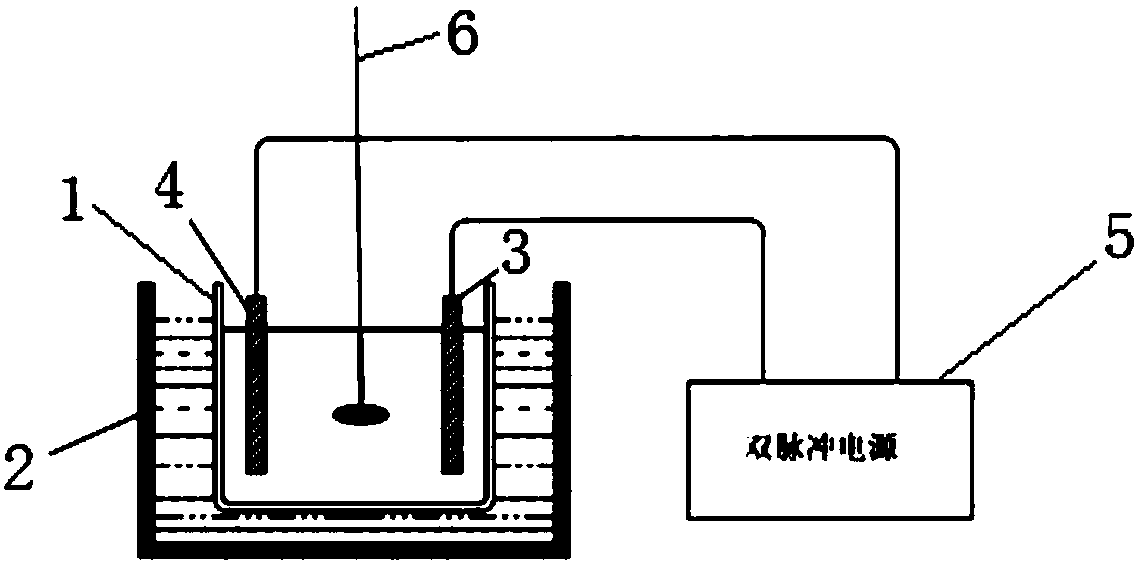

[0040] Double-pulse electrodeposition apparatus, such as figure 1 As shown, the plating tank 1 is included, the plating tank 1 is in the constant temperature water tank 2, there is a plating solution in the plating tank 1, and the cathode electrode 3, the anode electrode 4 and the electric stirrer 6 are placed in the plating solution, and the cathode electrode 3 and the anode electrode 4 are connected The double pulse power supply 5 and the electric stirrer 6 are located in the middle of the plating tank 1 . The plating tank 1 is a cuboid glass product whose specification is 100mm (length)×100mm (width)×80mm (height). The double pulse power supply 5 is responsible for providing rectangular wave current, the electric stirrer 6 controls the stirring speed during the reaction process, and the constant temperature water tank 2 contro...

Embodiment 2

[0083] The difference between this embodiment and Embodiment 1 is that the parameters of the double pulse power supply are: the forward duty cycle is 40%, the forward period is 9ms, and the forward current density is 1.75A / dm 2 , the reverse duty cycle is 20%, and the reverse current density is 0.15A / dm 2 , the prepared Ni-Mo / ZrO 2 Ni-Mo / ZrO in Ternary Gradient Functional Materials 2 The coating thickness is the largest.

Embodiment 3

[0085] The difference between this embodiment and Embodiment 1 is that the parameters of the double pulse power supply are: the forward duty cycle is between 40% and 80%, the forward period is 3ms, and the forward current density is 1.75A / dm 2 , the reverse duty cycle is 60%, and the reverse current density is 0.175A / dm 2 , the prepared Ni-Mo / ZrO 2 A coating with a ternary graded functional material grain size of about 17nm.

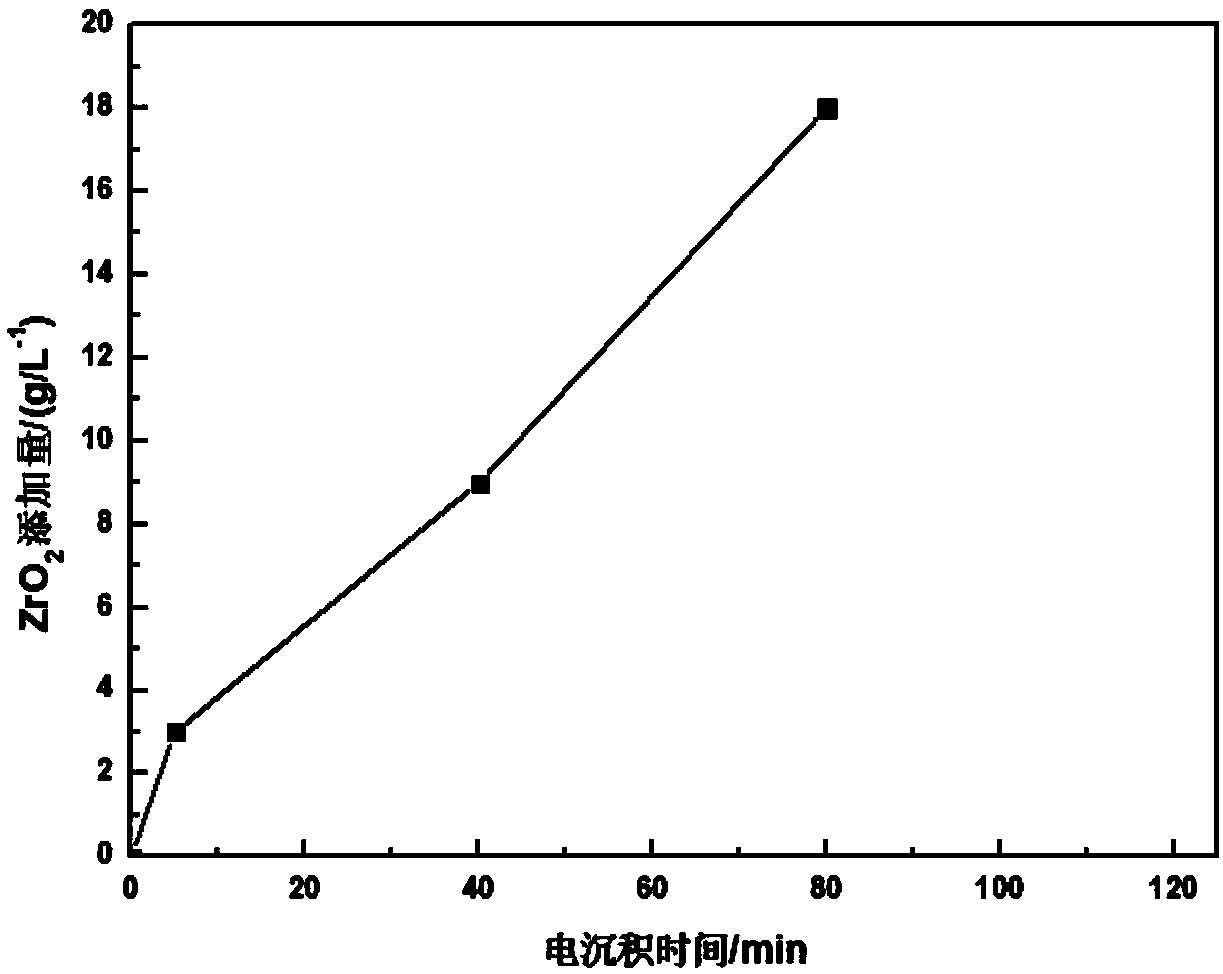

[0086] ZrO 2 The addition of the addition refines the crystal size of the coating, and the crystal size of the coating is the smallest (17.54nm) when the addition amount is 30g / L, making Ni-Mo / ZrO 2 The structure of the ternary graded functional material is more uniform and dense, and its corrosion resistance is obviously improved.

[0087] Ni-Mo / ZrO prepared by the present invention 2The ternary gradient functional material coating has smooth surface, compact structure, excellent performance, small average crystal size (about 17nm), good corrosion r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com