Loop heat pipe

A technology of loop heat pipe and road cover, which is applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large system space occupation, cumbersome and complicated layout of loop heat pipe transmission pipelines, etc., and achieve small space occupation, convenient and flexible layout , the effect of simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

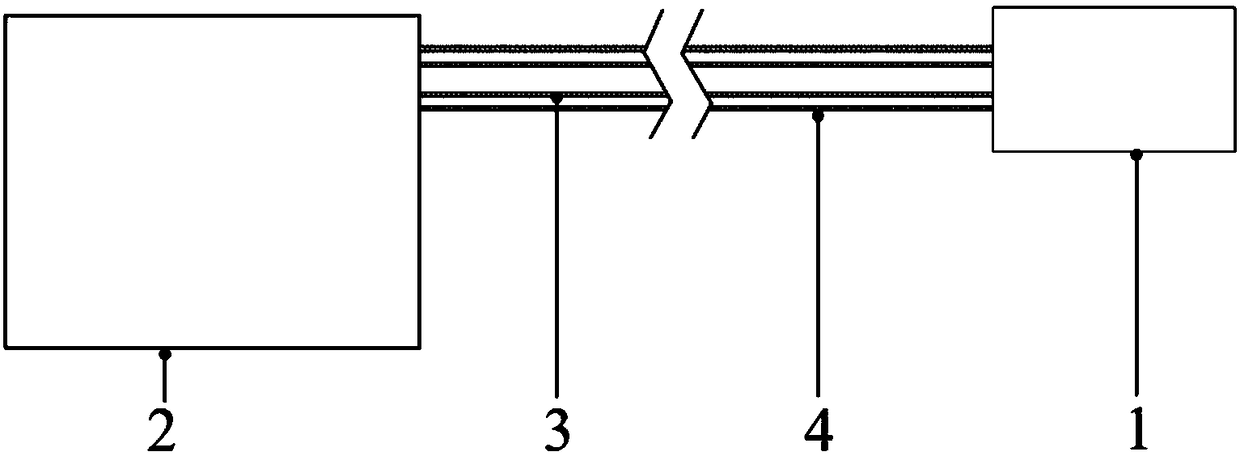

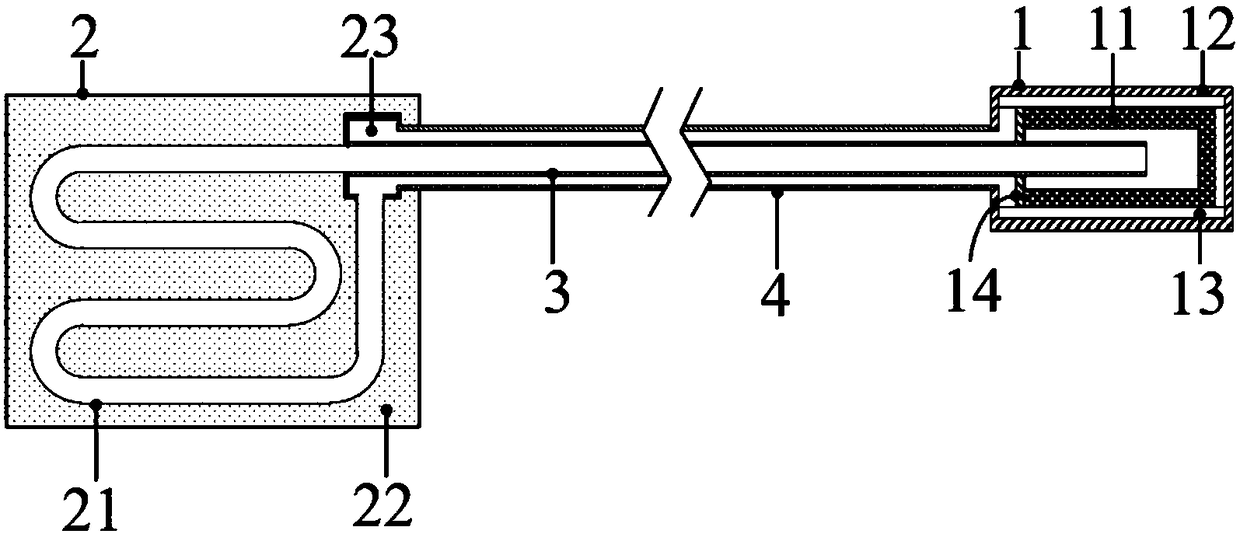

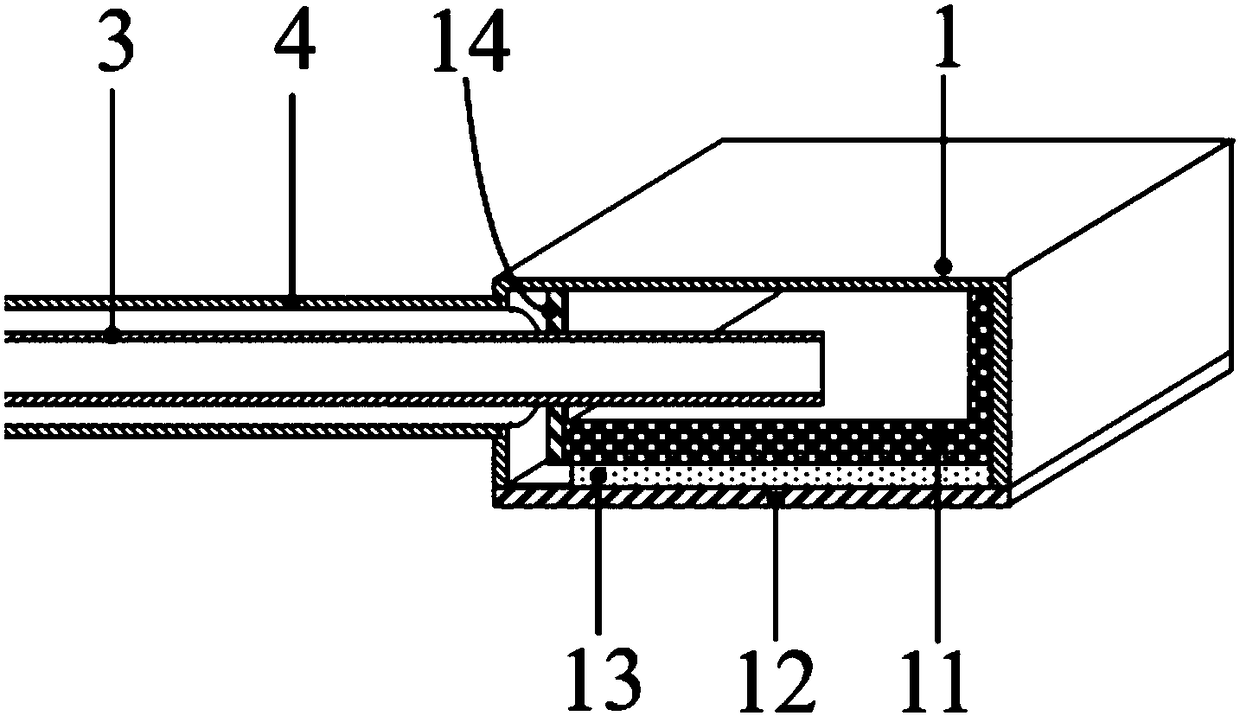

[0028] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a loop heat pipe, including an evaporator 1, a condenser 2, and a transmission pipeline for connecting the evaporator 1 and the condenser 2 to form a loop. The transmission pipeline includes a gas pipeline 4 and a liquid pipeline 3, the gas pipeline 4 is set in the liquid pipeline 3 or the liquid pipeline 3 is set in the gas pipeline 4. In this embodiment, the liquid pipeline 3 is set in the gas pipeline 4 to form a pipe sleeve In the transmission pipeline of pipe structure, the inlet of the gas pipeline 4 and the outlet of the liquid pipeline 3 are connected to the evaporator 1 , and the outlet of the gas pipeline 4 and the inlet of the liquid pipeline 3 are connected to the condenser 2 .

[0029] Further, the external shape of the evaporator 1 can be cylindrical, disc-shaped, flat or saddle-shaped, or in the form of a pipeline, and the inside of the evaporator 1 can be a cavity, o...

Embodiment 2

[0040] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described. at:

[0041] This embodiment also includes a gas storehouse 41, the gas pipeline 4 is connected to the gas storehouse 41 through a bypass pipeline, and when the loop heat pipe works in a low-temperature temperature zone, it can effectively prevent the internal pressure of the loop heat pipe from exceeding the safe range at room temperature, and at the same time When the loop heat pipe is running at low temperature, the gas working medium in the gas storage 41 can be continuously replenished into the loop heat pipe, so as to ensure that there is sufficient gas-liquid two-phase working medium in the loop heat pipe, through continuous phase change and circulation of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com