Wind power plant overhead flexible conductor section selection method

A technology of wind farms and flexible wires, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of not being able to fully adapt to the volatility of wind power generation and the number of hours is not high, so as to save investment and construction costs and save wires The effect of materials, great economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

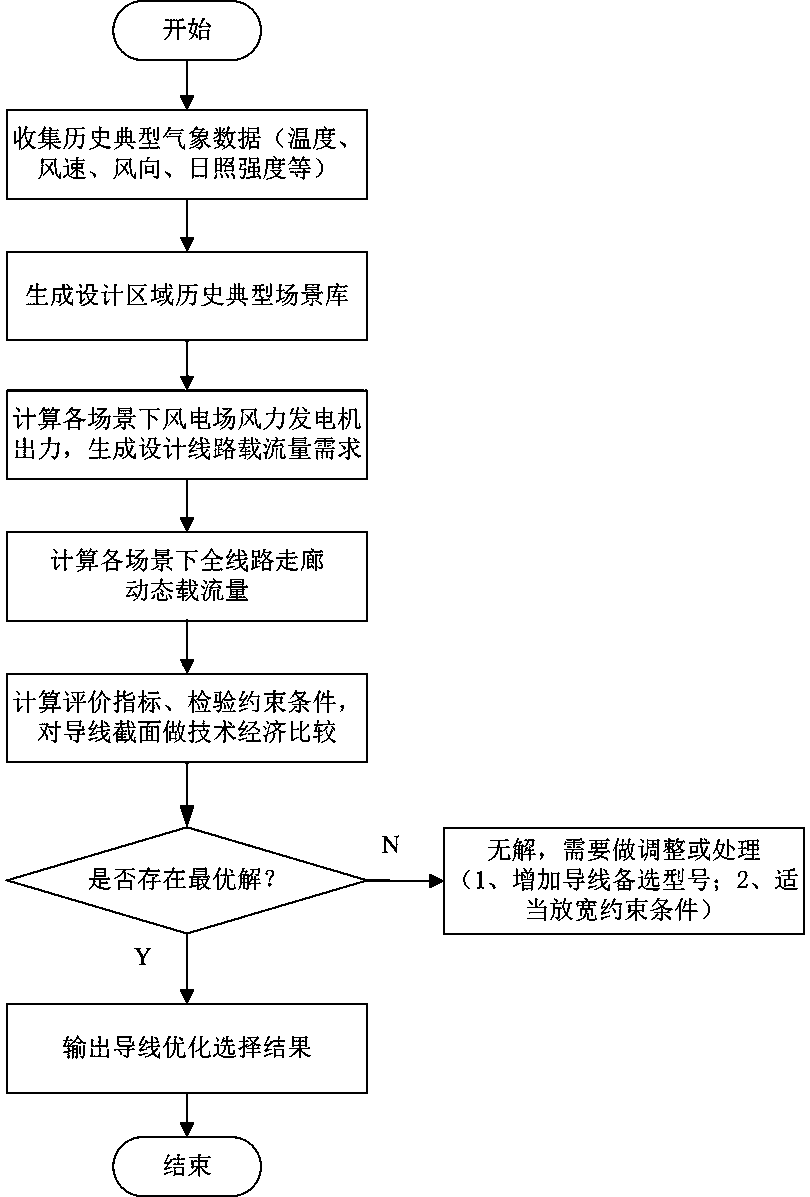

[0063] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

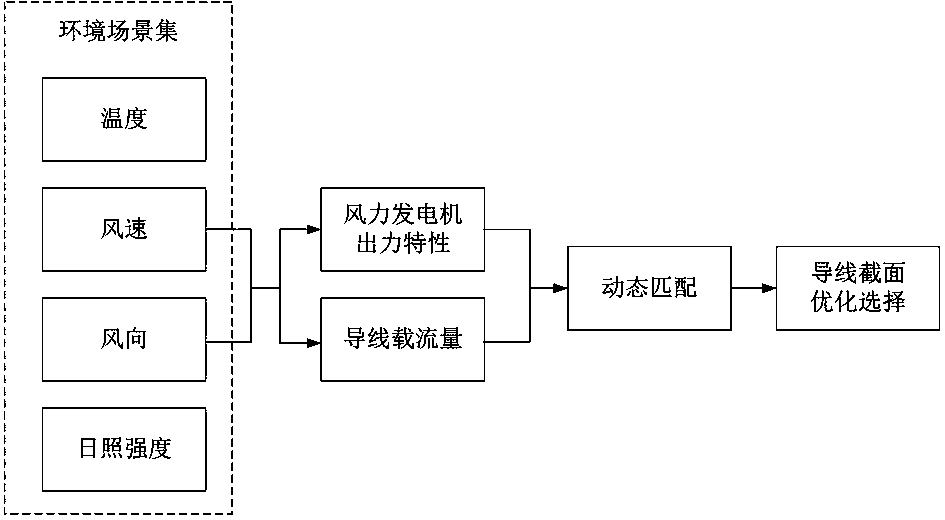

[0064] Such as figure 1 , image 3 As shown, the implementation method comprises the following steps: comprising the following steps:

[0065] Step 1: collect historical typical meteorological data, and generate historical typical scene database (scene collection) in the design area;

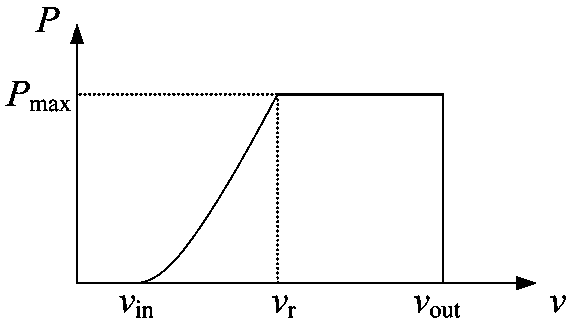

[0066] Step 2: Calculate the wind power generator output of the wind farm in each scenario, and simulate the processing curve. According to the typical wind speed space-time scene of the wind farm generated in step 1 and the output characteristics of the wind power generator configuration model of the wind farm, the wind power generation in the wind farm is obtained The output curve of the unit cluster in each typical scenario generates the carrying capacity requirement of the designed line;

[0067] Step 3: According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com