Clean error correcting method of solar module and solar module system using same

A solar module and error correction technology, applied in the direction of photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve the problems of output result error at the cleaning time point, the reduction of solar module power generation power, and the inability to fully meet the economic benefits. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

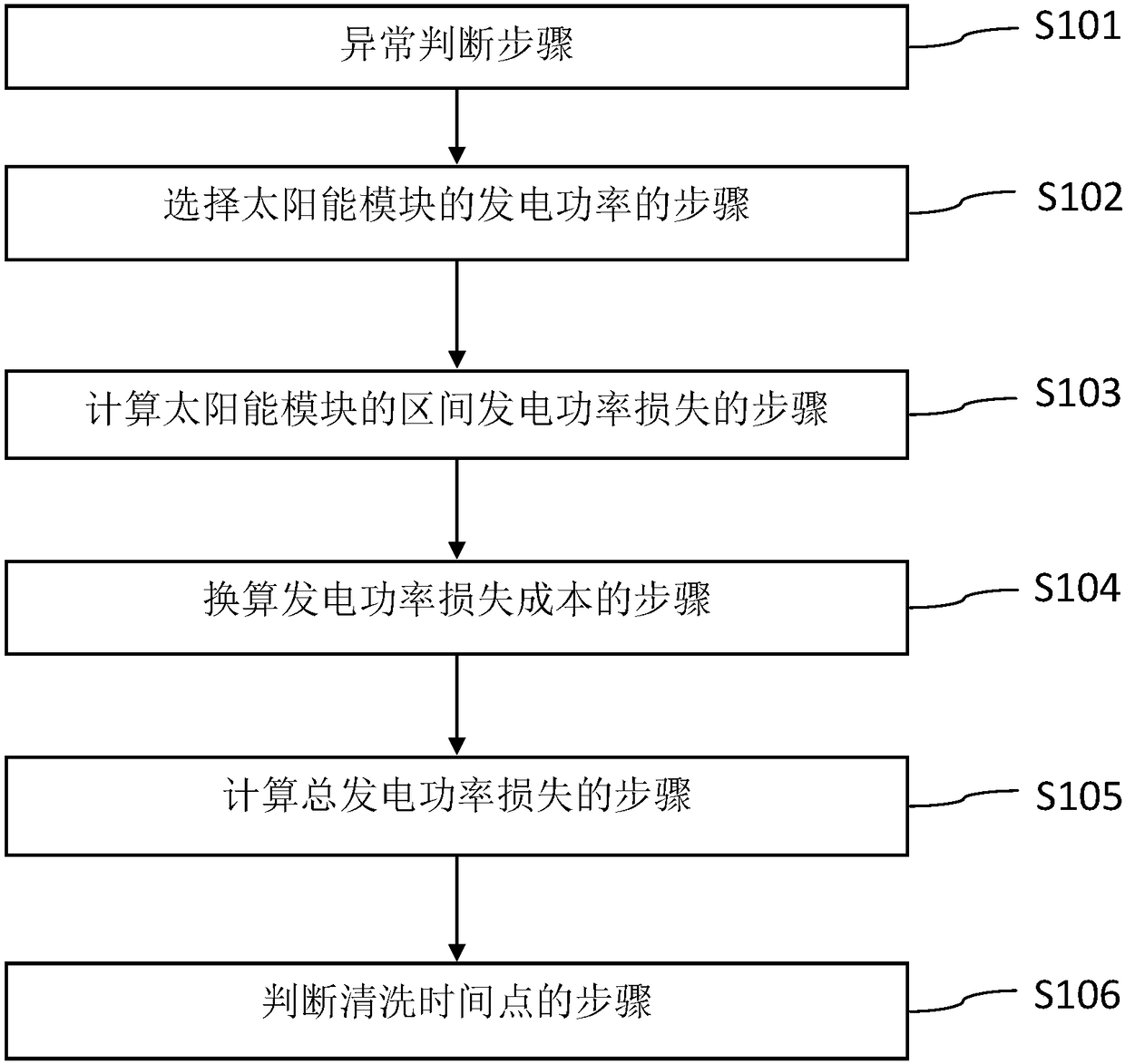

[0038] combine figure 1 and figure 2 to illustrate. The first embodiment of the present invention provides an error correction method for solar module cleaning, including:

[0039] In the abnormal judgment step (S101), when all components of the solar module system are in normal operation and the sunshine rate is sufficient but the output voltage of the solar module is lower than the rated voltage, it is determined that there are external factors that cause the power generation to drop, further affecting the power generation based on the power generation. Power generation power to be calculated;

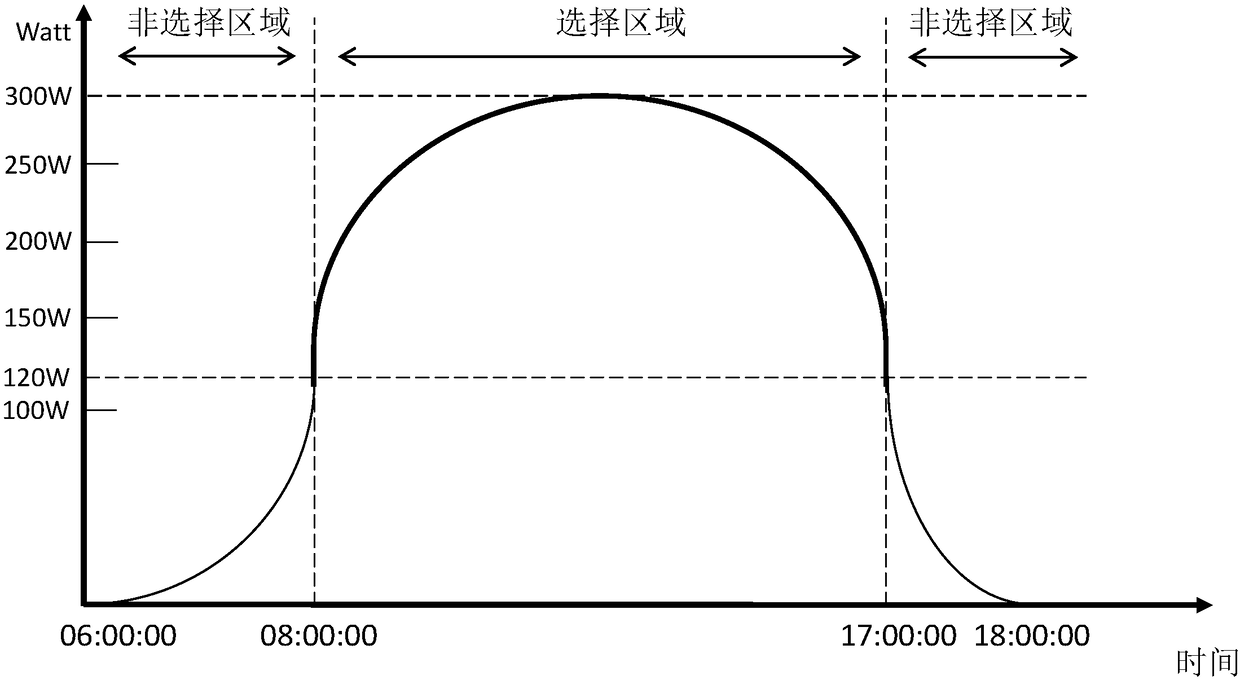

[0040] The step of selecting the generating power of the solar module (S102), select the generating power of the generating power of the solar module in the range of more than 40% of the rated generating power as the generating power to be calculated (refer to figure 1 );

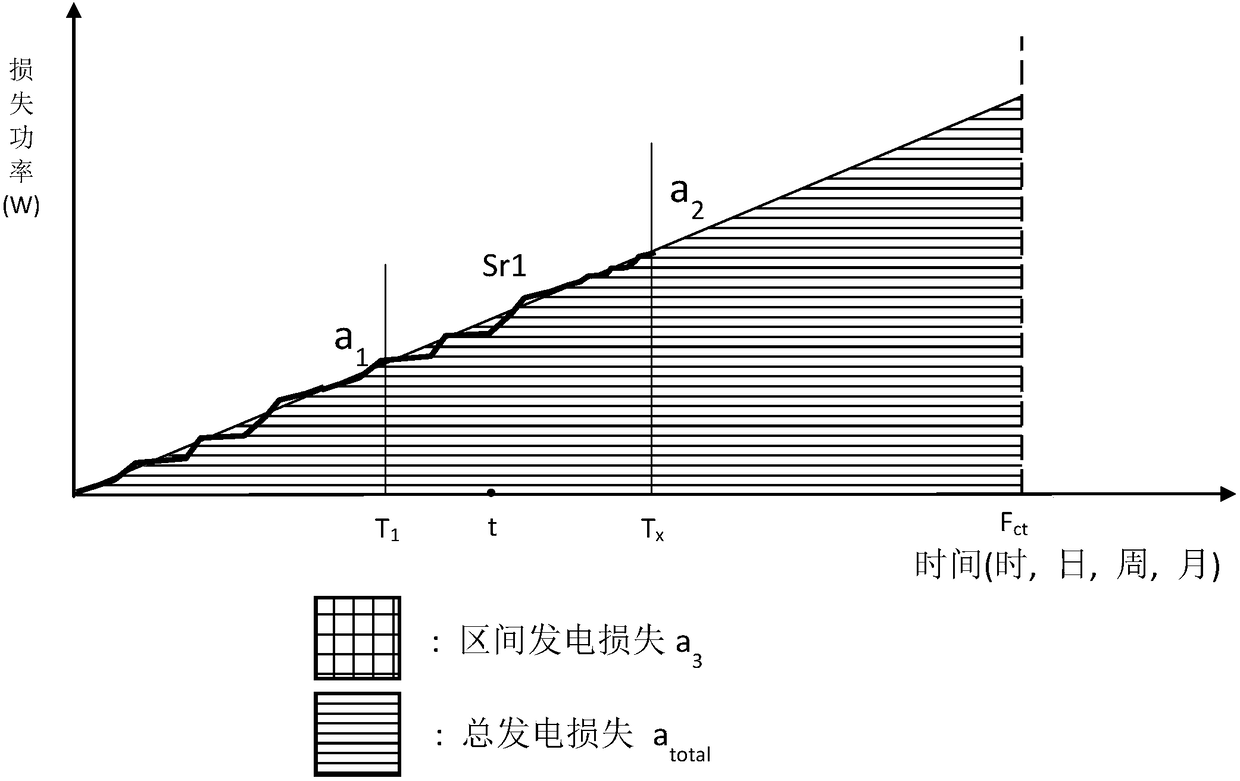

[0041] The step of calculating the interval generating power loss of the solar module (S103), using the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com