Combined cyclone baffling large-caliber gas-liquid re-separation device for gas compressor

A gas compressor and separation device technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that the splash of condensed water cannot be well prevented, the size of the cylinder body is insufficient, and the flow rate of the air inlet is high. , to achieve excellent separation effect, improve performance and service life, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

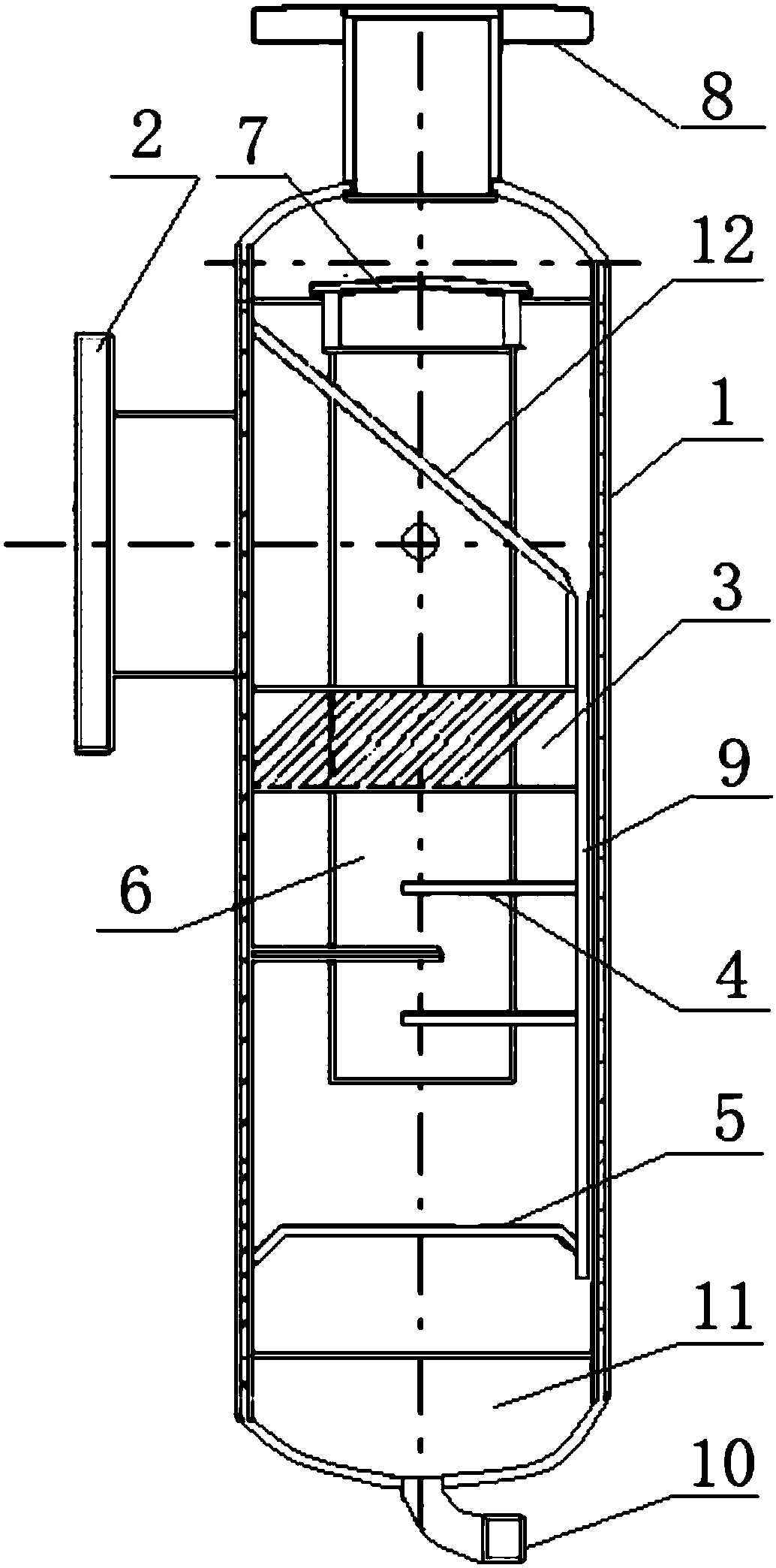

Embodiment 1

[0025] Embodiment 1: as attached figure 1 As shown, the housing 1 is in the shape of a vertical circular tube, the upper outer wall of the housing 1 is fixed with an air inlet 2, the top of the housing 1 is fixed with an air outlet 8, and the air inlet 2 is located on the lower side of the upper outlet of the housing 1. The cyclone fins 3 are fixed on the inner wall of the body 1, and the angle between the cyclone channel formed by the interlayer of any two adjacent cyclone fins 3 and the vertical central axis of the housing 1 is 35-55°, and the shell on the lower side of the cyclone fins 3 The baffle plate 4 is fixed on the inner wall of the body 1, and the guide tube 6 is erected and fixed in the middle of the shell 1. The lower end of the guide tube 6 is opened on the lower side of the baffle plate 4, and the outer wall of the upper end of the guide tube 6 is fixed by an annular connecting plate. On the inner wall of the housing 1 higher than the air inlet 2, and the upper ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap