Circulating granulation fluidized bed device of low-temperature, low-turbidity, high-turbidity or high-alga water treatment

A technology of fluidized bed and high-algae water, which is applied in water/sewage treatment equipment, water/sewage treatment, water treatment parameter control, etc. It can solve the problems of poor ability to change water quality load and achieve good removal effect and improve effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

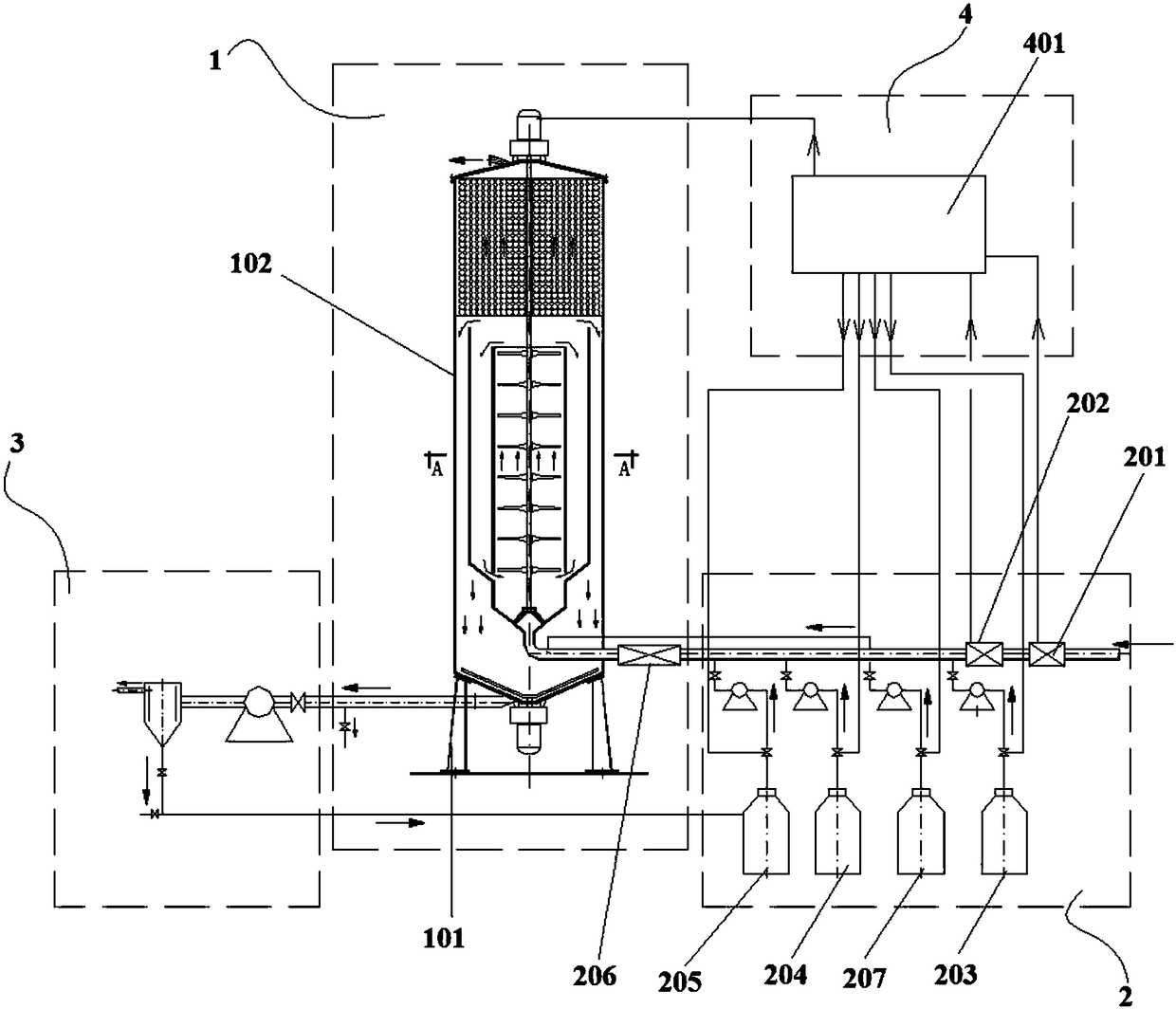

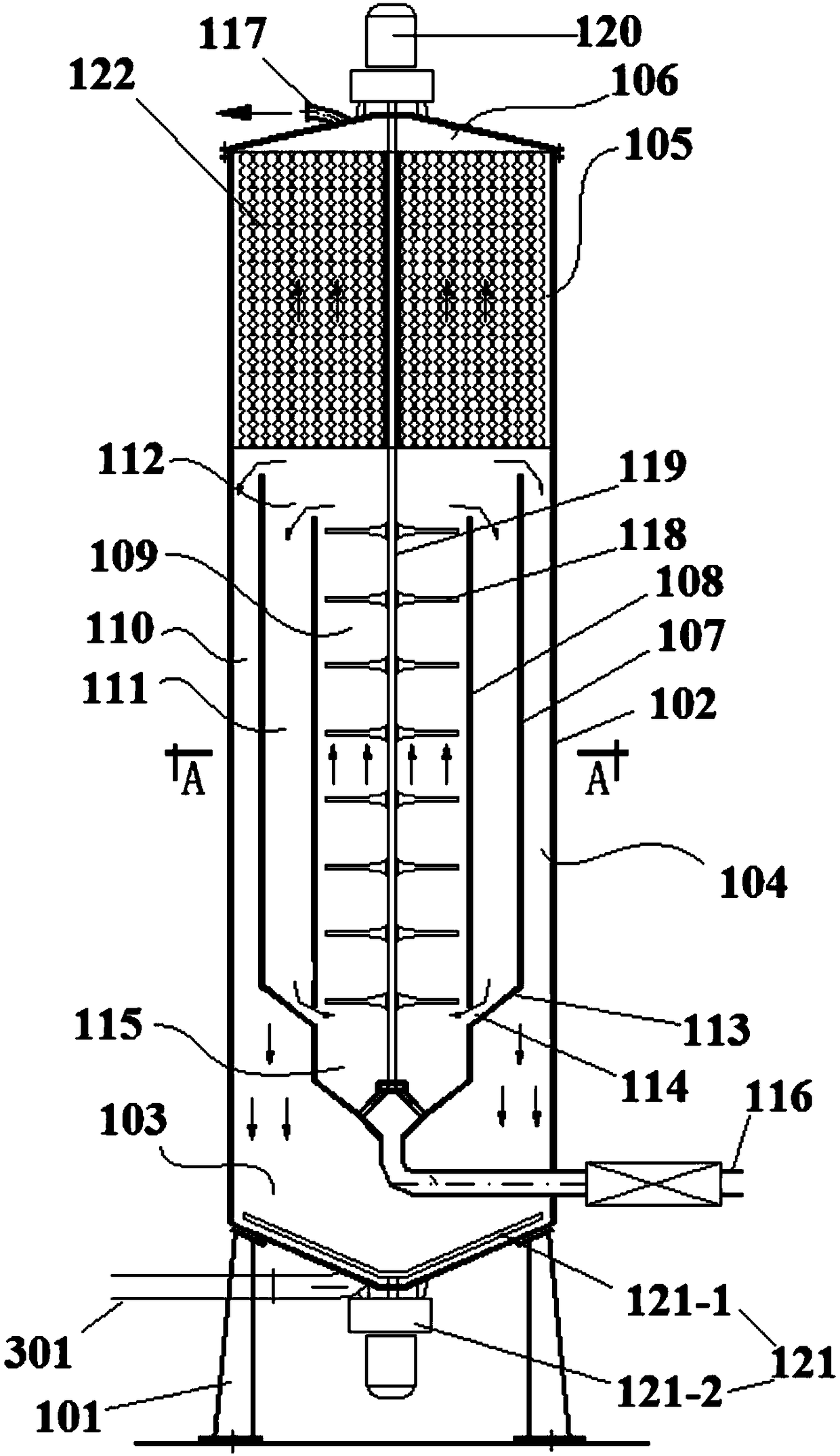

[0047] Comply with the above technical solutions, such as Figure 1 to Figure 5 As shown, this embodiment provides a circulating granulation fluidized bed equipment for low-temperature low-turbidity, high-turbidity or high-algae water treatment, including a fluidized bed main device 1, a drug dosing system 2, a mud-water separation system 3 and an automatic Control system 4; the main body device 1 of the fluidized bed includes a base frame 101, and a tank body 102 is fixedly installed on the base frame 101, and the tank body 102 is sequentially composed of a sludge concentration zone 103, a circulation granulation zone, and zone 104, vertical vortex separation zone 105 and catchment zone 106;

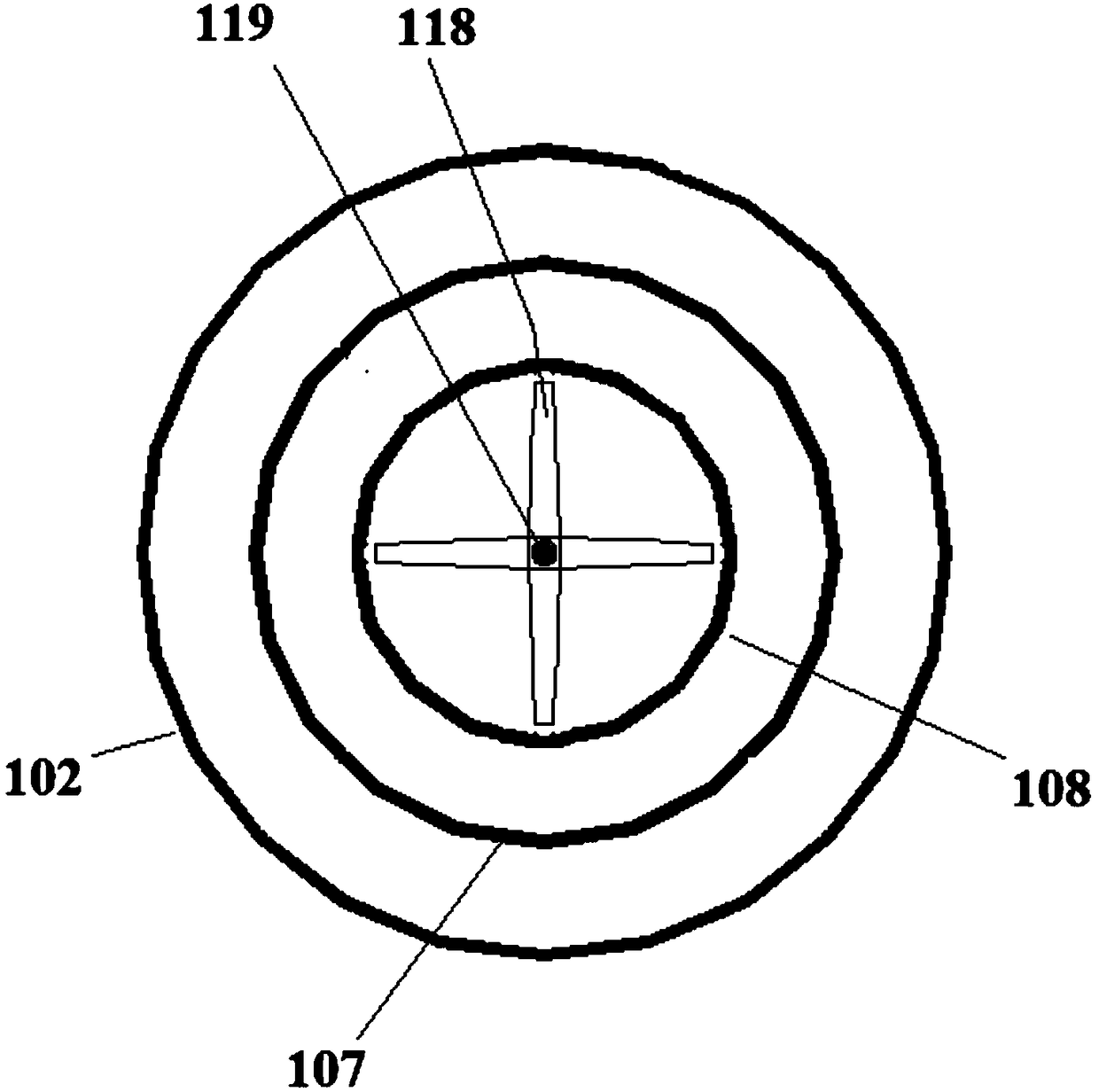

[0048] A middle cylinder 107 and an inner cylinder 108 are installed in the circulating granulation zone 104, the tank body 102, the middle cylinder 107 and the inner cylinder 108 are coaxially arranged sequentially from the outside to the inside, and the inner cylinder 108 is a granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com