Method for simultaneously extracting paclitaxel and 10-DABIII (10-Deacetyl Baccatin III) from taxus chinensis

A technology of paclitaxel and yew, applied in the direction of organic chemistry, can solve the problems of increasing process difficulty and cost, and achieve the effects of avoiding oxidative degradation, short preparation time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

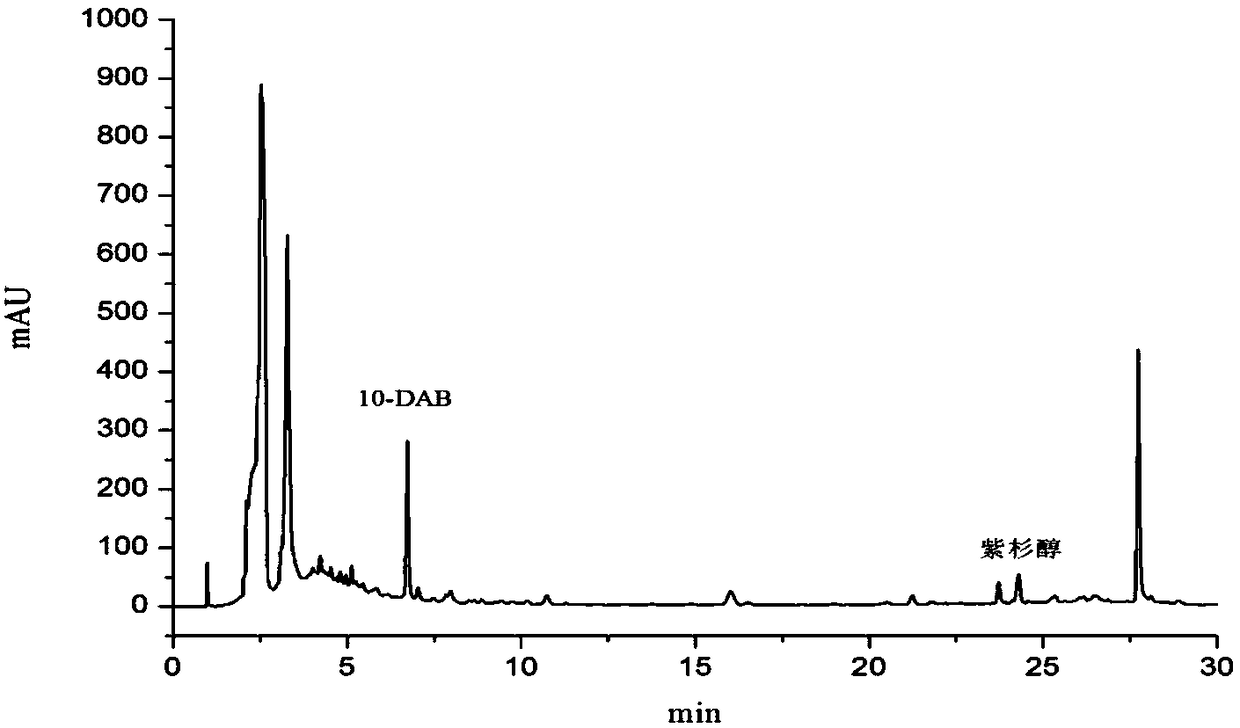

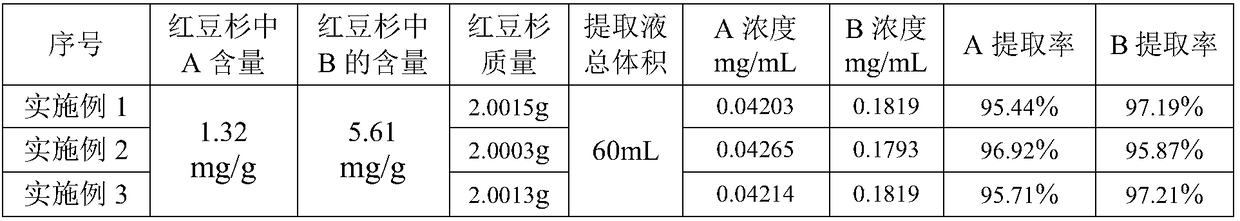

[0019] First, crush the branches and leaves of Taxus chinensis to 50 mesh, add 90% volume fraction of ethanol to soak, and the solid-liquid ratio of Taxus chinensis powder and extraction solvent is 1:50 (g / ml). Then, the mixed liquid is poured into the crushing and extracting device for extraction. The extraction temperature is 16°C and the extraction pressure is 200MPa. It is crushed and extracted under low temperature and high pressure, and paclitaxel and 10-DABⅢ in the yew are rapidly dissolved into the extraction solvent. Finally, the supernatant and the precipitate were separated by centrifugation, and the obtained supernatant was the extract of paclitaxel and 10-DABⅢ.

Embodiment 2

[0021] First, crush the branches and leaves of Taxus chinensis to 200 mesh, add 60% volume fraction of ethanol to soak, and the solid-liquid ratio of Taxus chinensis powder and extraction solvent is 1:10 (g / ml). Then, the mixed solution is poured into the crushing extraction device for extraction. After the extraction is completed, the solution is poured into the crushing extraction device for extraction, and the extraction is performed continuously for 3 times. The extraction temperature is 4°C, and the extraction pressure is 50 MPa. Under low temperature and high pressure conditions, Paclitaxel and 10-DABⅢ in Taxus quickly dissolved into the extraction solvent. Finally, the supernatant and the precipitate were separated by centrifugation, and the obtained supernatant was the extract of paclitaxel and 10-DABⅢ.

Embodiment 3

[0023] First, crush the branches and leaves of Taxus chinensis to 100 mesh, add 80% volume fraction of ethanol to soak, and the solid-liquid ratio of Taxus chinensis powder and extraction solvent is 1:20 (g / ml). Then, the mixed solution is injected into the crushing extraction device, and after the extraction is completed, the solution is poured into the crushing extraction device for extraction, continuous extraction is performed twice, the extraction temperature is 8°C, the extraction pressure is 125MPa, and the extraction is crushed and extracted under low temperature and high pressure. Paclitaxel and 10-DABⅢ in Taxus quickly dissolved into the extraction solvent. Finally, the supernatant and the precipitate were separated by centrifugation, and the obtained supernatant was the extract of paclitaxel and 10-DABⅢ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com