Preparation method of microbial cadmium removal absorbent and application of absorbent in cadmium removal of powder food

A technology of microorganisms and adsorbents, applied in the application of cadmium removal from powder food, the field of preparation of microbial cadmium removal adsorbents, can solve the problems such as the difficulty of separating microbial cadmium removal adsorbents from powdery raw materials, and achieve easy separation and reduce Effect of cadmium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

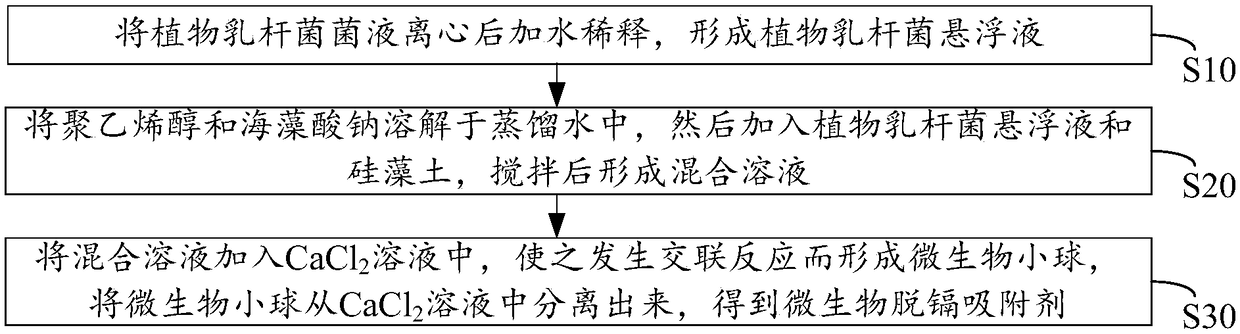

[0035] The present invention proposes a preparation method of a microbial cadmium removal adsorbent, figure 1 It is an embodiment of the preparation method of the microbial cadmium removal adsorbent provided by the present invention. see figure 1 , the preparation method of the microbial cadmium removal adsorbent comprises the following steps:

[0036] Step S10, centrifuging the Lactobacillus plantarum liquid and diluting it with water to form a Lactobacillus plantarum suspension;

[0037] In this embodiment, step S10 specifically includes: centrifuging the Lactobacillus plantarum cultured to the logarithmic phase at a speed of 4000-6000 r / min for 8-12 minutes, removing the supernatant, and taking sterile water for colony precipitation Dilute to OD 620 (The absorbance value at 620 nm) was 1.5, and a suspension of Lactobacillus plantarum was obtained. Wherein, the Lactobacillus plantarum liquid can be obtained by cultivating the Lactobacillus plantarum to the logarithmic ph...

Embodiment 1

[0055] (1) Centrifuge the Lactobacillus plantarum cultured to the logarithmic phase at 4000r / min for 12min, remove the supernatant, take the colony precipitate and add sterile water to dilute to OD 620 is 1.5, obtains plantarum lactobacillus suspension;

[0056] (2) Dissolve 2g of polyvinyl alcohol and 3g of sodium alginate in 84g of distilled water by heating, sterilize at 121°C for 30min, cool to 37.5°C, and then add 10g of Lactobacillus plantarum suspension prepared in step (1) and 1g of silicon Alginate, stir well to form a mixed solution;

[0057] (3) Use a 1mL syringe to draw the mixed solution, and drop it into 4°C, 4% CaCl 2 solution, cross-linked at 4°C for 24h to form microbial pellets, filtered from CaCl 2 Microbe pellets are separated from the solution and washed three times with sterile water to prepare a microbial cadmium-removing adsorbent.

Embodiment 2

[0059] (1) Centrifuge the Lactobacillus plantarum cultured to the logarithmic phase at 5000r / min for 10min, remove the supernatant, take the colony precipitate and add sterile water to dilute to OD 620 is 1.5, obtains plantarum lactobacillus suspension;

[0060] (2) Dissolve 1.5g of polyvinyl alcohol and 2.5g of sodium alginate in 83.8g of distilled water by heating, sterilize at 120°C for 33min, cool to 36.5°C, and then add 11g of Lactobacillus plantarum suspension prepared in step (1) and 1.2g of diatomaceous earth, after being stirred evenly, a mixed solution is formed;

[0061] (3) Draw up the mixed solution with a 1mL syringe, and add 3.5% CaCl at 3.5°C drop by drop. 2 solution, cross-linked at 3.5°C for 26h to form microbial pellets, filtered from CaCl 2 Microbe pellets are separated from the solution and washed three times with sterile water to prepare a microbial cadmium-removing adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com