Test equipment for analyzing structure of loose accumulation body

A technology of structural analysis and test equipment, applied in particle size analysis, particle and settlement analysis, soil material testing, etc., can solve the problem of not being able to directly observe the accumulation structure and vertical particle size distribution characteristics of the accumulation body, and unable to obtain the internal structure characteristics of the accumulation body , flat-mouth sampling tubes cannot be tightly fitted to the site, etc., to achieve the effect of facilitating mass production and widely popularizing and using, simplifying equipment manufacturing and operation difficulty, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

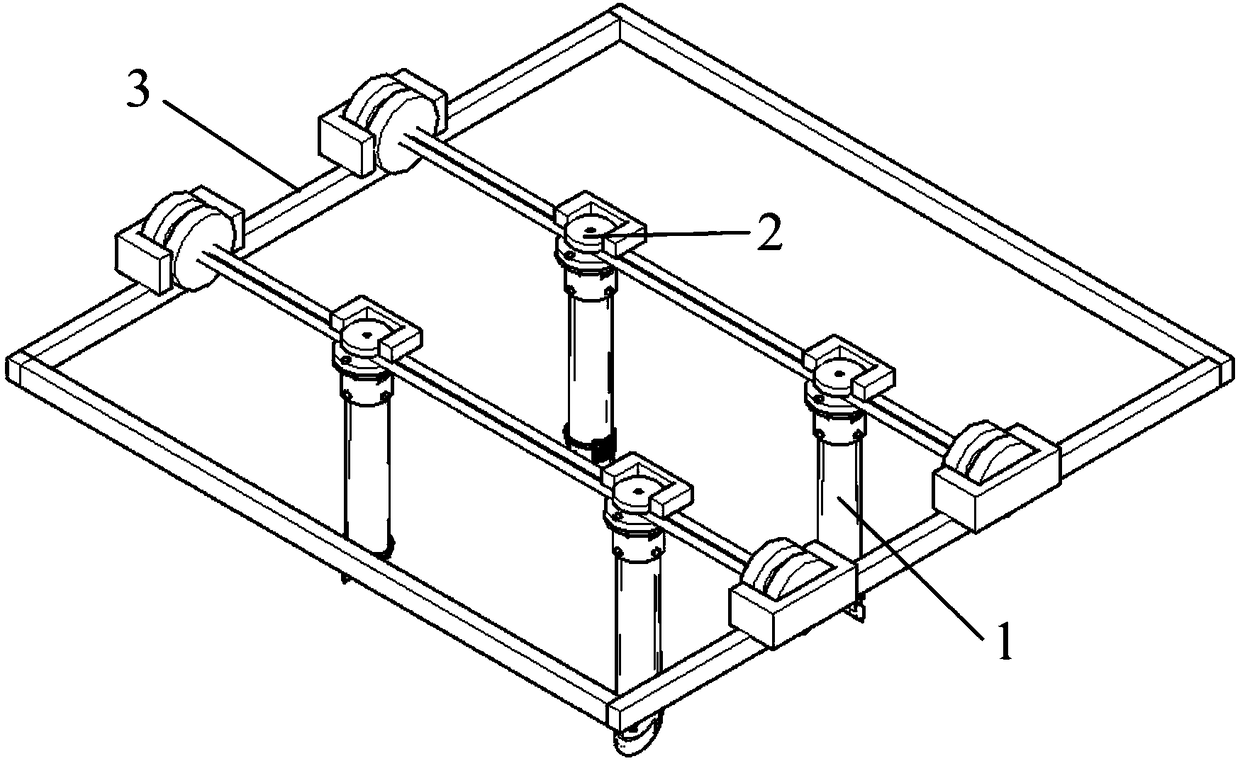

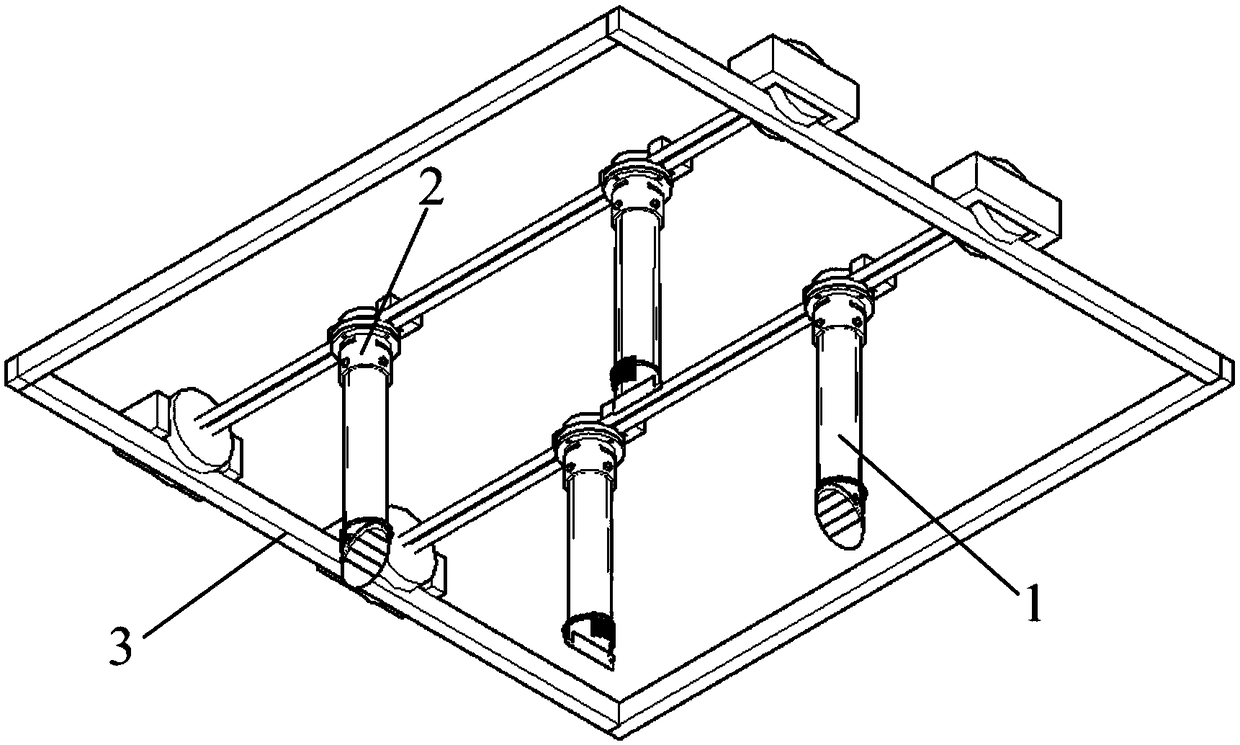

[0027] refer to figure 1 and figure 2 , a loose accumulation body structure analysis test equipment specially used for undulating terrain, including three constituent units of sampling device 1, connecting device 2 and sampling point control device 3, the detailed structures of the three constituent units are as follows:

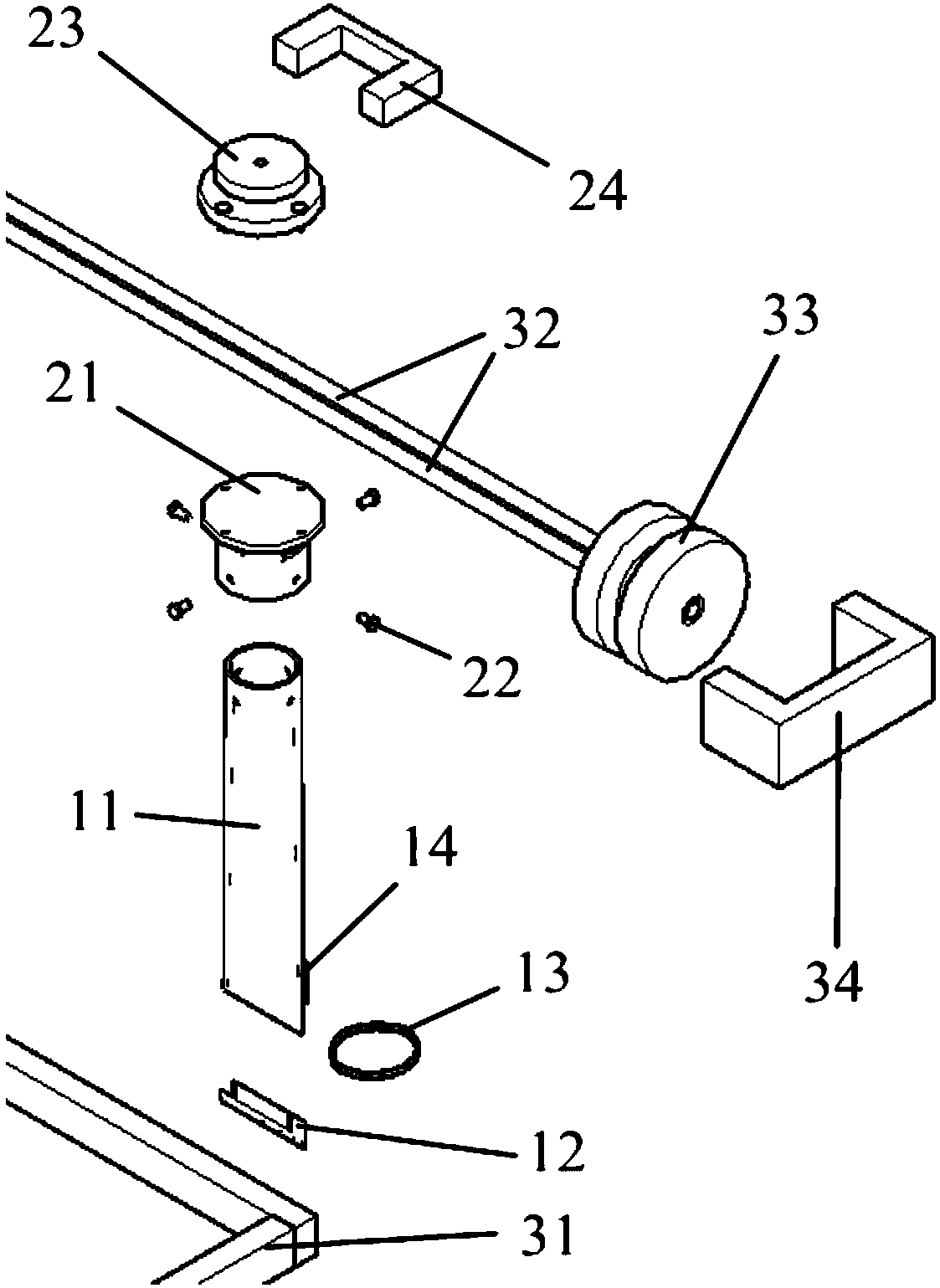

[0028] refer to image 3 The sampling device 1 includes a sampling tube (including a scale) 11 , a tube seal 12 , a rubber band (string) 13 and a rubber band slot 14 on the side wall of the tube end. The pipe seal 12 is inserted into the mouth of the pipe from bottom to top along the inclined slope and sealed. The rubber ring (rib) 13 fastens the sampling tube (including scale) 11 and the pipe seal 12 to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com