Vacuum pump, and flexible cover and rotor used in said vacuum pump

A vacuum pump and rotor technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids to achieve the effect of inhibiting backflow, corrosion and rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

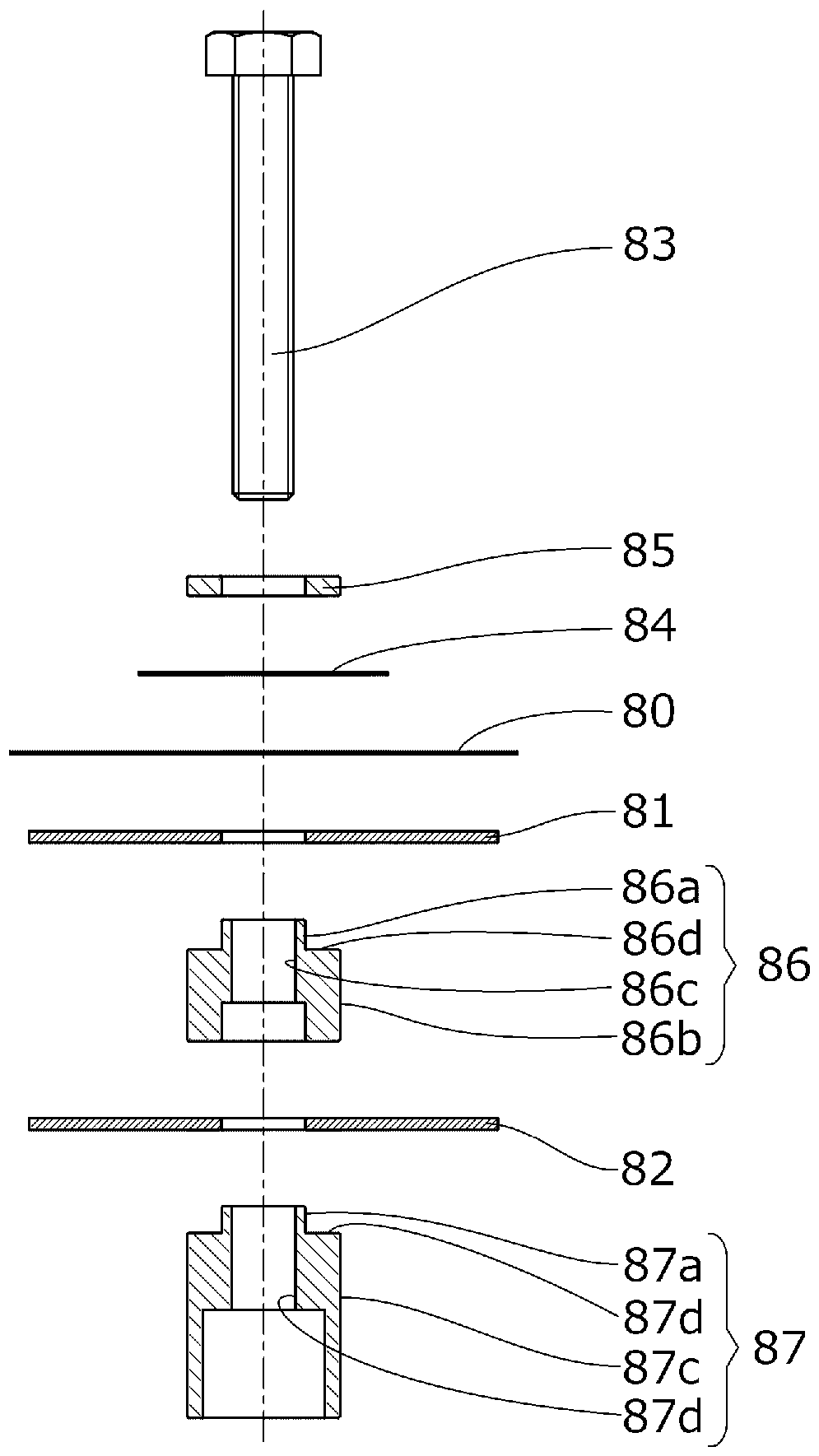

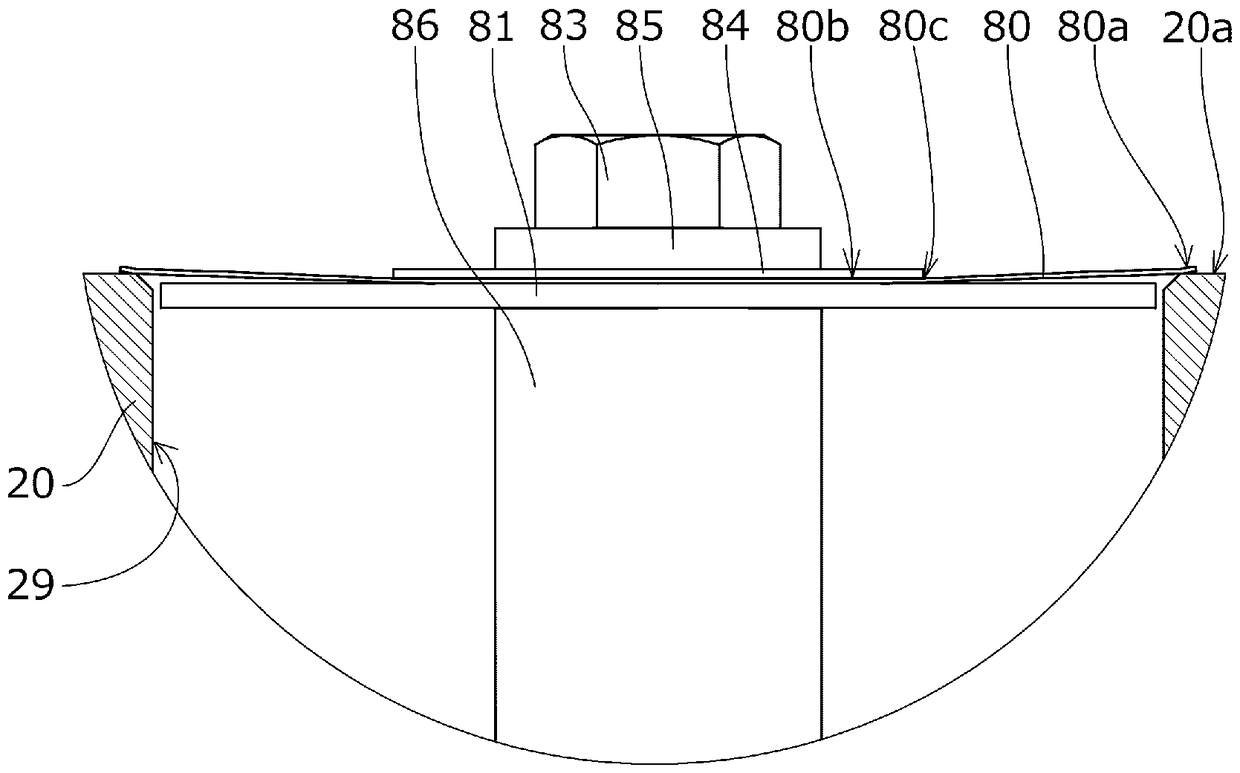

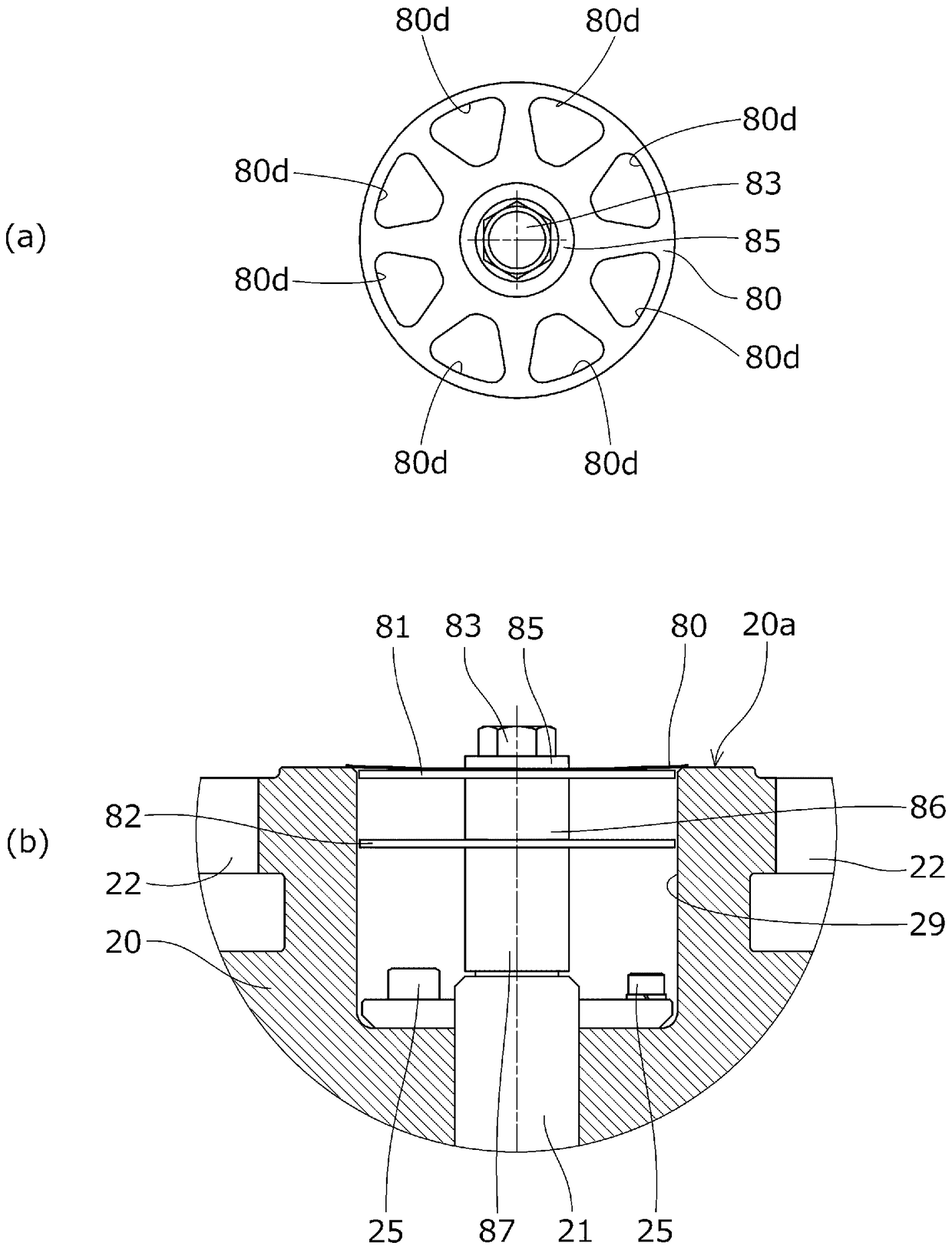

[0041] Hereinafter, a vacuum pump 1 according to an embodiment of the present invention will be described based on the drawings. In addition, hereinafter, regarding the words "upper" and "lower", the intake port side and the exhaust port side in the rotor axial direction correspond to upper and lower sides, respectively.

[0042] figure 1 It is a longitudinal sectional view showing the vacuum pump 1 . The vacuum pump 1 is a compound pump including a turbomolecular pump mechanism PA and a thread groove pump mechanism PB housed in a substantially cylindrical housing 10 .

[0043] The vacuum pump 1 includes: a housing 10; a rotor 20 having a rotor shaft 21 rotatably supported in the housing 10; a drive motor 30 for rotating the rotor shaft 21; Stator post 40.

[0044] The casing 10 is formed in a bottomed cylindrical shape. The housing 10 is composed of a base 11 with a gas exhaust port 11a formed on the lower side and a cylindrical portion 12 with a gas intake port 12a forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com