Preparation method of skimmed linseed powder and usage of skimmed linseed powder

A technology of flaxseed powder and flaxseed, which is applied in the field of preparation of defatted flaxseed powder, can solve the problems of chemical reagent residue, low solubility, unfavorable comprehensive utilization, etc., and achieve the effect of improving cancer prevention and anticancer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

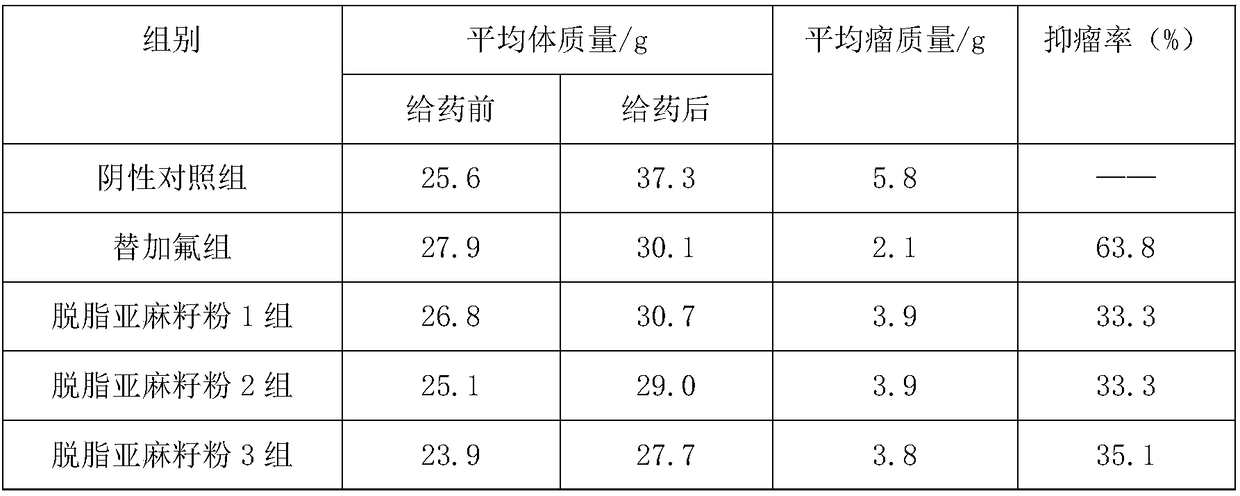

Examples

Embodiment 1

[0025] A preparation method of defatted flaxseed meal includes the following steps:

[0026] 1) Detoxification of flaxseeds: mix flaxseeds with water in a mass ratio of 1:5, and treat them with a microwave power of 500W for 1 min. Wash the treated flaxseeds with water and dry them to obtain detoxified flaxseeds;

[0027] 2) Flaxseed degreasing: through supercritical CO 2 The extraction method squeezes the oil rich in flaxseed, the extraction time is 40min, the extraction temperature is 50℃, the extraction pressure is 10MPa, and the CO 2 The concentration is 0.7g / mL, CO 2 The flow rate is 4mL / min to obtain defatted flaxseed meal;

[0028] 3) Preparation of flaxseed meal: mix the defatted flaxseed meal obtained in step 2) with water according to a mass ratio of 1:4, and vacuum concentrate to a solid content of 13%; homogenize twice with a high-pressure homogenizer, The homogenization pressure is 40Mpa; a pressure spray dryer is used for spray drying. The inlet temperature of the spray ...

Embodiment 2

[0030] A preparation method of defatted flaxseed meal includes the following steps:

[0031] 1) Detoxification of flaxseeds: mix flaxseeds with water in a mass ratio of 1:20, and treat them with a microwave power of 800W for 3min, rinse the treated flaxseeds with water and dry them to obtain detoxified flaxseeds;

[0032] 2) Flaxseed degreasing: through supercritical CO 2 The extraction method is used to squeeze the oil rich in linseed, the extraction time is 60min, the extraction temperature is 70℃, the extraction pressure is 15MPa, CO 2 The concentration is 0.9g / mL, CO 2 The flow rate is 4mL / min to obtain defatted flaxseed meal;

[0033] 3) Preparation of flaxseed meal: mix the defatted flaxseed meal obtained in step 2) with water in a mass ratio of 1:6, and vacuum concentrate until the solid content is 16% by mass; homogenize twice with a high-pressure homogenizer, The homogenization pressure is 50 MPa; a pressure spray dryer is used for spray drying. The inlet temperature of the ...

Embodiment 3

[0035] A preparation method of defatted flaxseed meal includes the following steps:

[0036] 1) Detoxification of flaxseeds: mix flaxseeds with water according to a mass ratio of 1:12, and treat them with a microwave power of 650W for 2 minutes. Wash the treated flaxseeds with water and dry them to obtain detoxified flaxseeds;

[0037] 2) Flaxseed degreasing: through supercritical CO 2 The extraction method squeezes the oil rich in flaxseed, the extraction time is 50min, the extraction temperature is 60℃, the extraction pressure is 12MPa, and the CO 2 The concentration is 0.8g / mL, CO 2 The flow rate is 4mL / min to obtain defatted flaxseed meal;

[0038] 3) Preparation of flaxseed meal: mix the defatted flaxseed meal obtained in step 2) with water in a mass ratio of 1:5, and vacuum concentrate until the solid content is 15% by mass; homogenize twice with a high-pressure homogenizer, The homogenization pressure is 45MPa; the pressure spray dryer is used for spray drying, the inlet tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com