Slag breaking apparatus for biomass combustor and realization method

A burner, biomass technology, applied in combustion equipment, solid fuel combustion, grain processing, etc., can solve the problems of slagging, high smoke exhaust temperature, low combustion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to understand the present invention more clearly, the present invention is described in detail in conjunction with the accompanying drawings and embodiments.

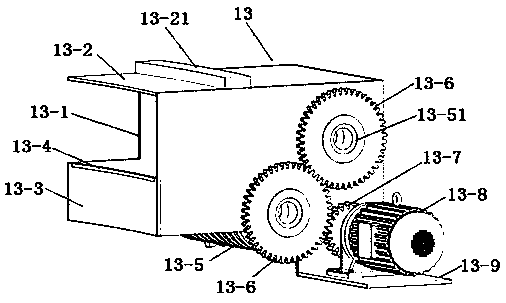

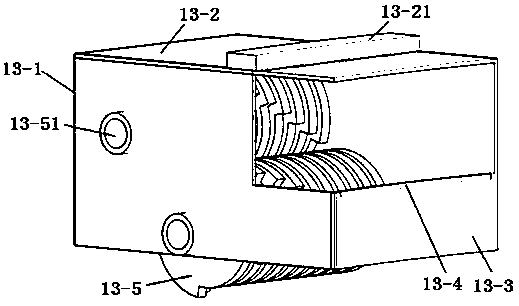

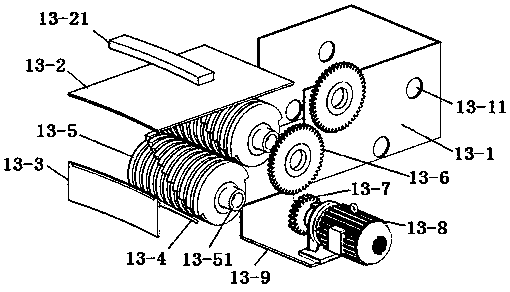

[0022] Such as Figure 1 to Figure 4 As shown, a slag breaking device for biomass burners, including guide plate 13-4, ash discharge box 13-1, ash discharge box cover 13-2, slag breaker 13-5, motor I 13-8 , motor frame 13-9, bull gear 13-6 and pinion 13-7.

[0023] The slag breaker 13-5 includes a shaft 13-51 and an eccentric wheel 13-52.

[0024] The center of the eccentric wheel 13-52 is the shaft hole II 13-52-1, one side of the central shaft hole II 13-52-1 is a large semicircle 13-52-2, and the other side along the center is a small semicircle 13-52-3, and the large The junction of the semicircle 13-52-2 and the small semicircle 13-52-3 is the two end faces 13-52-4 of the large semicircle; several eccentric wheels 13-52 are fixed on the shaft through the shaft hole II 13-52-1 On 13-51, a circle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com