Welded pipe rustproof treatment device and construction method thereof

A technology of anti-rust treatment and construction method, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven anti-rust paint spraying of welded pipes, achieve high work efficiency, prevent environmental pollution, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

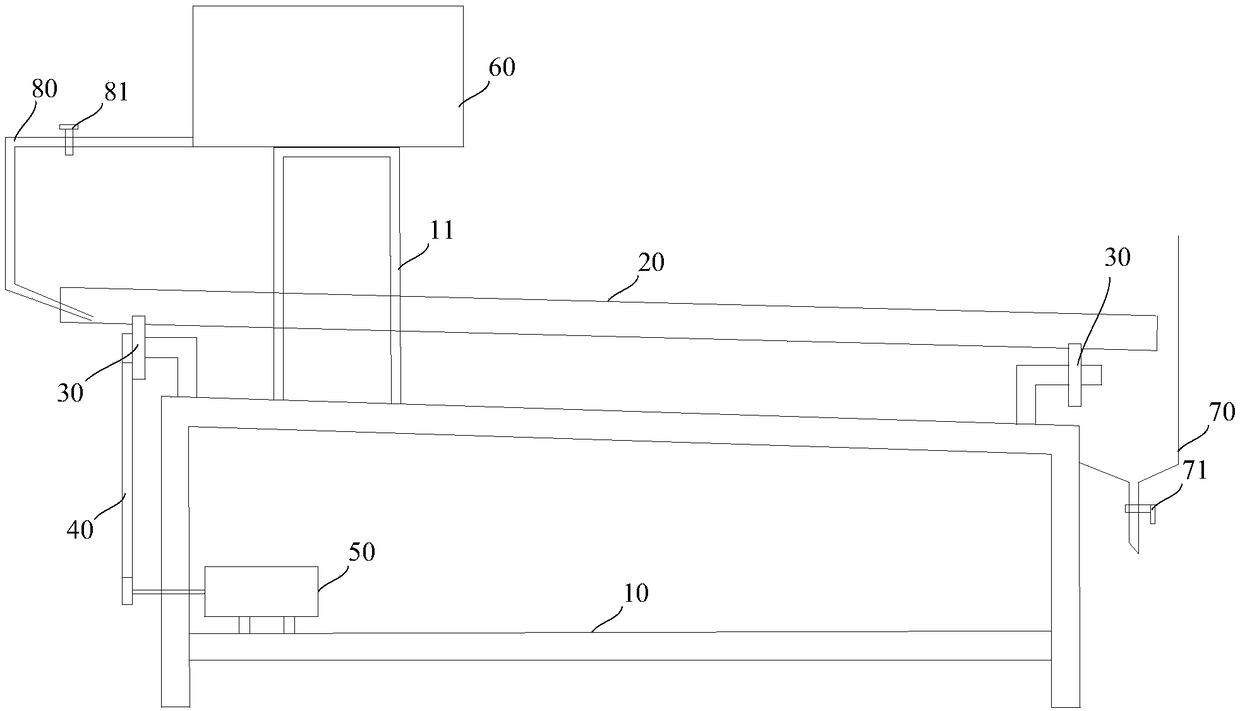

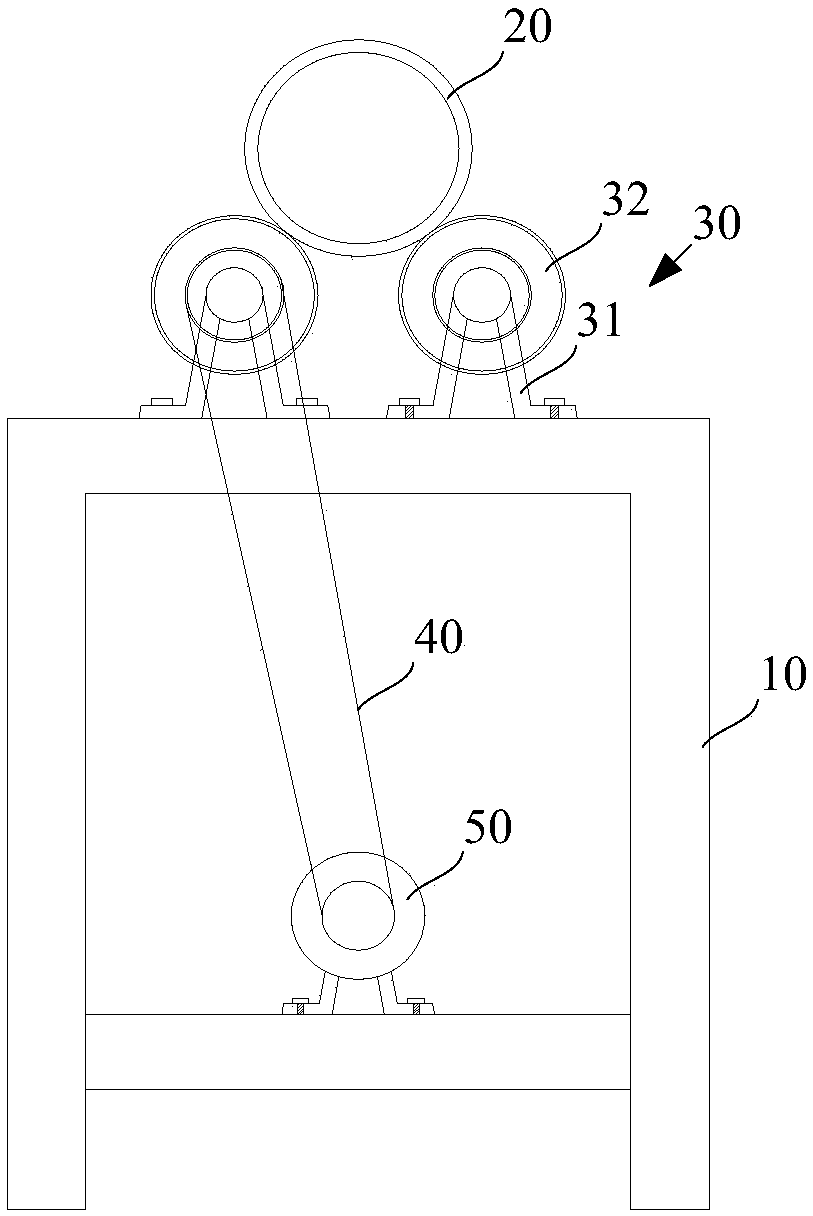

[0038] refer to figure 1 , shows the front view of the antirust treatment device for welded pipes of the present invention. refer to figure 2 , shows a side view of the antirust treatment device for welded pipes of the present invention. combine figure 1 and figure 2 As shown, the antirust treatment device for welded pipes of the present invention includes: an operating platform 10; a pair of rolling structures 30 detachably installed on the operating platform 10, and the top elevations of the pair of rolling structures 30 are different so that they are supported on a pair of rolling structures. The welded pipe 20 on the structure 30 is arranged in an inclined shape, and a pair of rolling structures 30 pass through to drive the welded pipe 20 supported on it to rotate; the storage tank 60 installed on the operation platform 10 and equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com