An automatic appearance sorting system for small forged parts and its working method

A sorting system and working method technology, applied in sorting and other directions, can solve problems such as low sorting efficiency, uncertain errors, and obstacles to fully automatic production lines, and achieve good production continuity, good applicability, and economical The effect of detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

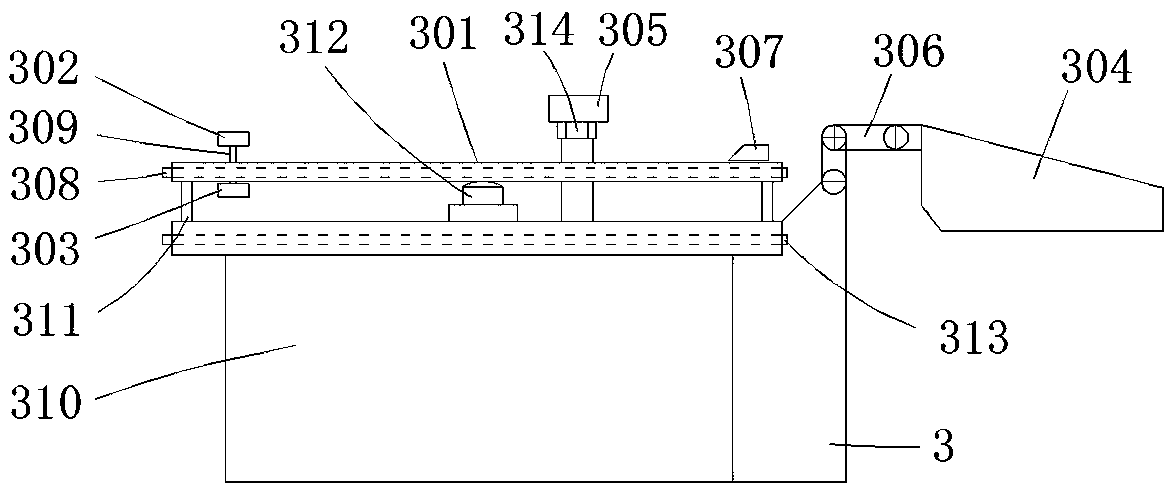

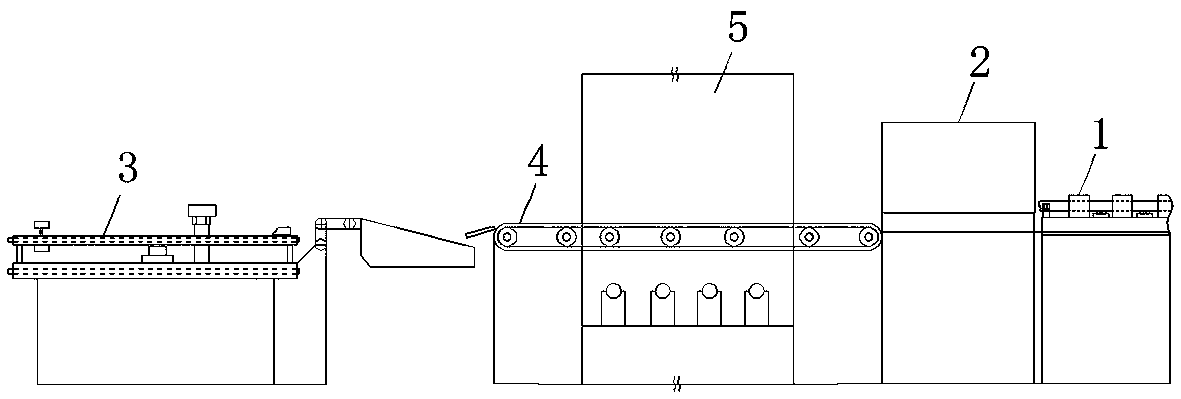

[0028] An automatic appearance sorting system for small forged parts of the present invention, such as figure 1 with figure 2 As shown, a sorting device 3 is included, and the sorting device 3 includes a base 310, an observation platform 301, an upper detection device 302, a lower detection device 303, a storage hopper 304 and a sorting manipulator 305, and the observation platform 301 passes through a The set of movable support parts 311 is movably connected with the base 310, and the observation platform 301 is connected with an eccentric vibration device 312, the upper detection device 302 and the lower detection device 303 are connected with the image processing center of the control unit, and the observation Table 301 is made of transparent material.

[0029] In this embodiment, the upper detection device 302 and the lower detection device 303 are respectively arranged on the upper side and the lower side of the observation platform 301 .

[0030] In this embodiment, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com