420N1 stainless steel continuous annealing acid pickling welding method

A welding method and stainless steel technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of surface scratches, broken strips, poor materials, etc., to increase strength, improve surface quality and success rate, and avoid broken band effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

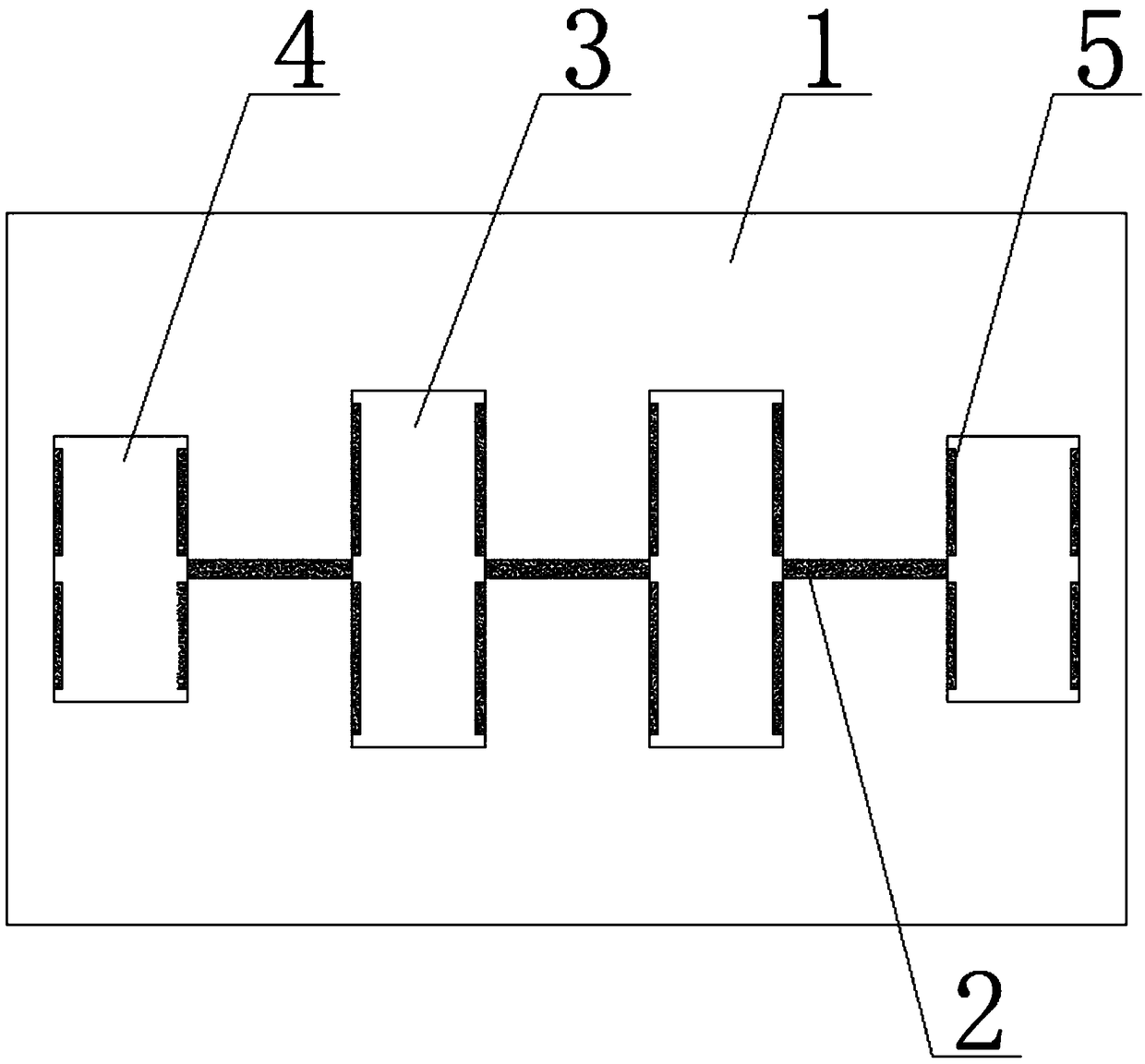

[0022] Such as figure 1 As shown, a 420N1 stainless steel continuous annealing and pickling welding method is characterized in that it is carried out according to the following steps:

[0023] S1 welding of front and rear steel coils 1, when 420N1 stainless steel is continuously annealed and pickled, the MIG welding machine is used to weld the front and rear steel coils to obtain the first weld 2;

[0024] S2 welds the overlapping blocks, and welds the overlapping blocks on the first welding seam of the front and rear steel coils 1 to increase the strength of the welded part;

[0025] The lapping blocks include a first lapping block 3 and a second lapping block 4, the first lapping block 3 is longer than the second lapping block 4, two kinds of lapping blocks are respectively arranged, and the first lapping block 3 is located at the front and back In the middle of the steel coil 1, the second overlapping block 4 is located on both sides of the first overlapping block 3 and cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com