Circular track magnetic levitation vehicle energy storage system

A circular track and energy storage system technology, applied in propulsion systems, vehicle components, electric vehicles, etc., can solve the problems of large sensors and controllers, high power consumption and low reliability of electromagnetic levitation technology, and achieve flexible response power Adjustment, low cost, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

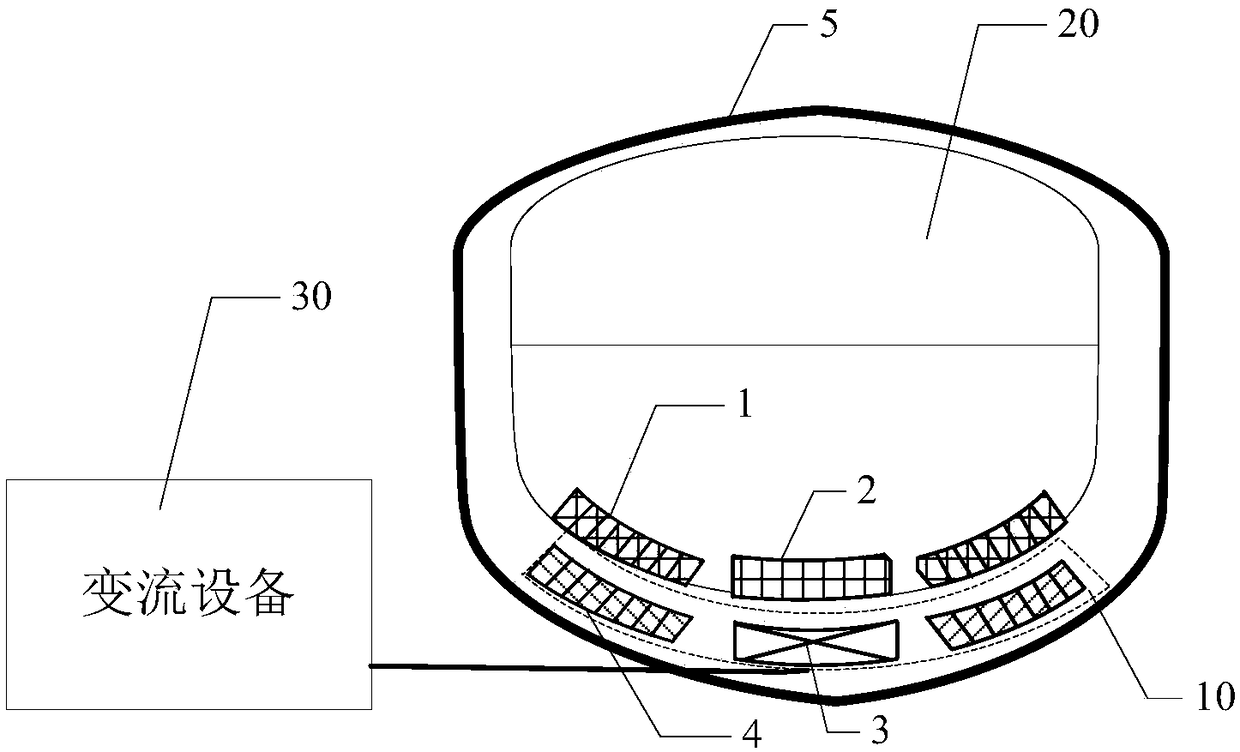

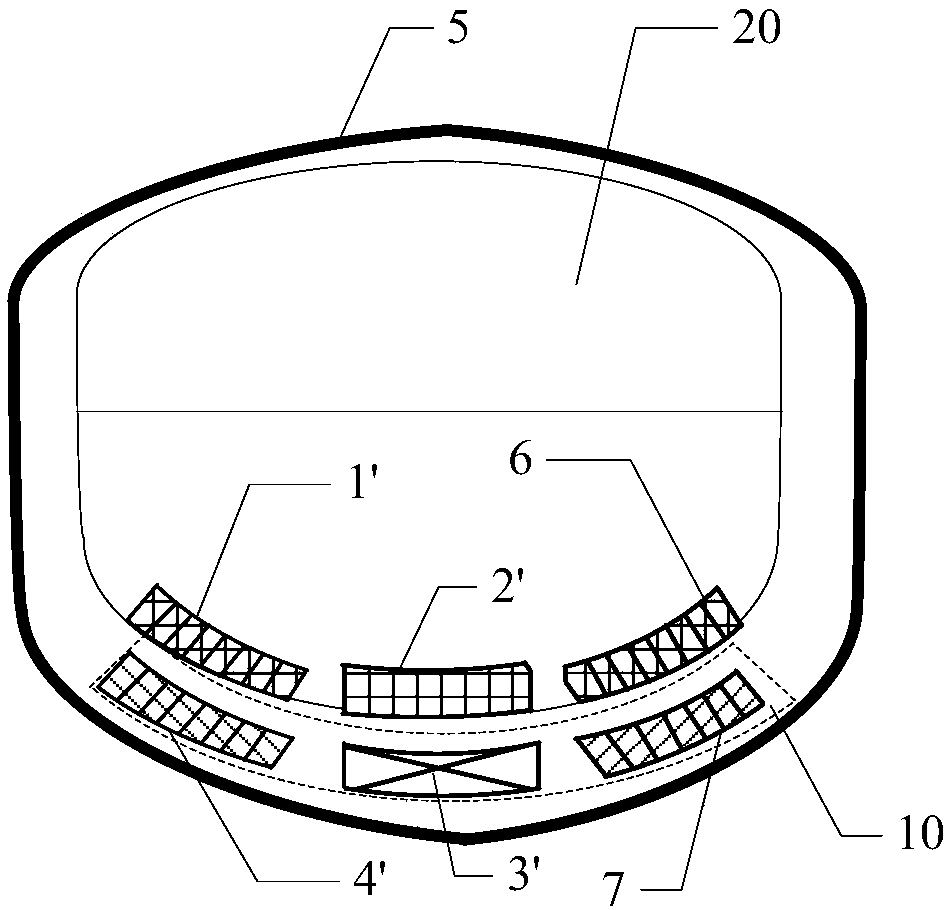

[0048] Such as figure 2 In the shown embodiment 1 of the present invention, viewed from a cross section, the vehicle 20 includes a first vehicle-mounted permanent magnet block 1' and a second vehicle-mounted permanent magnet block 6, and the first vehicle-mounted permanent magnet block 1' and the second vehicle-mounted permanent magnet block 1' The magnet blocks 6 are concentratedly arranged at the lower part of the vehicle; the track 10 may include the first track permanent magnet block 4' and the second track permanent magnet block 7, the first track permanent magnet block 4' and the second track permanent magnet block 7 is also correspondingly concentrated on the top of the track. The first vehicle-mounted permanent magnet block 1', the second vehicle-mounted permanent magnet block 6, the first track permanent magnet block 4' and the second track permanent magnet block 7 are all composed of a plurality of small permanent magnets, thereby ensuring the running stability of t...

Embodiment 2

[0050] Such as image 3 The shown embodiment 2 of the present invention, viewed from the cross section, the first track permanent magnet block 4', the second track permanent magnet block 7, the first controllable track 10 used to realize the suspension and guidance of the vehicle The heights of the excitation module 8 and the second controllable excitation module 9 are higher than the positions of the first vehicle-mounted permanent magnet block 1 ′ and the second vehicle-mounted permanent magnet block 6 in the vehicle 20 . The first controllable excitation module 8 and the second controllable excitation module 9 are hybrid magnets composed of electric excitation and permanent magnets, which can increase the running stability of the vehicle.

Embodiment 3

[0052] Such as Figure 4 In the shown embodiment 3 of the present invention, from the cross section, when the track is U-shaped, the first track permanent magnet block 4' and the second track permanent magnet block 7 in the track 10 can be used Permanent magnets with rounded rectangular sides are used instead. The first controllable excitation module 8 and the second controllable excitation module 9 are also hybrid magnets composed of electric excitation and permanent magnets, and the shape of the hybrid magnets becomes a long rectangle. At this time, the shape of the cavity formed by the track wall 5 also becomes a rounded rectangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com