Method for preparing three crystal configuration type calcium carbonate granules

A calcium carbonate and particle technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of complex preparation methods and difficult coexistence, and achieve the effects of high repeatability, strong operability, and strong potential economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

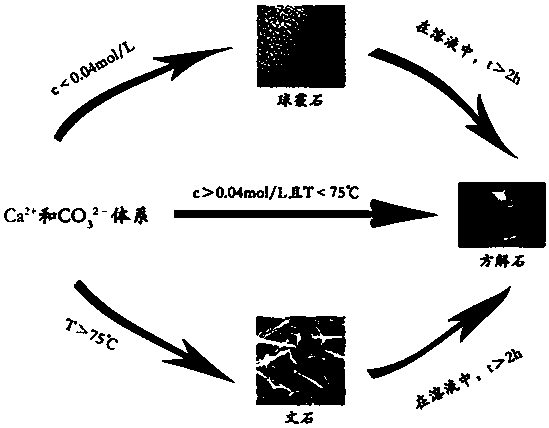

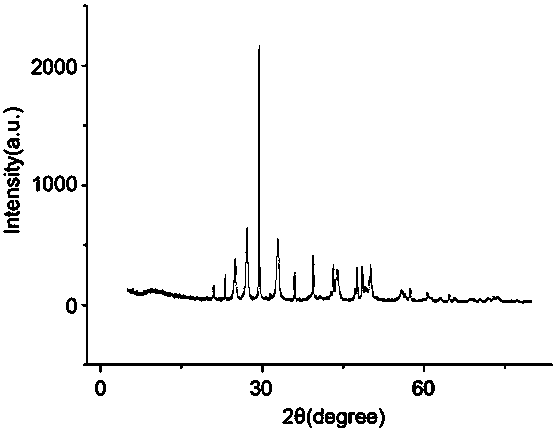

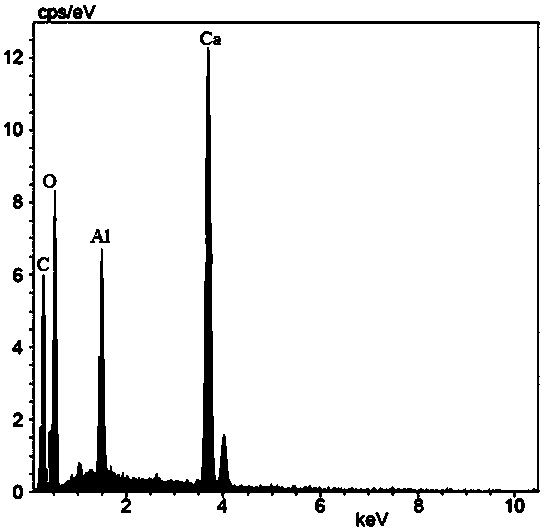

[0040] Carbonate ion (carbonate ion source is Na 2 CO 3 ) and calcium ions (the source of calcium ions is anhydrous CaCl 2 ) in a 1:1 equal concentration to prepare a salt solution system and place it in a 500mL beaker. After the saline solution system was ultrasonically oscillated for 10 min, the beaker was placed on a magnetic stirrer and magnetically stirred at a speed of 1000 rad / min. At 25°C, when the concentration of carbonate ions and calcium ions is 0.04mol / L and the reaction time is 1h, the salt solution system will generate vaterite-type calcium carbonate; the concentration of carbonate ions and calcium ions is 0.1mol / L, and the reaction temperature When the temperature is 75°C and the reaction time is 1.2h, the salt solution system will generate aragonitic calcium carbonate; when the reaction temperature is 25°C, the concentration of carbonate ions and calcium ions is 0.1mol / L, and the reaction time is 1h, the Salt solution systems generate calcite-type calcium c...

Embodiment 2

[0042] Carbonate ion (carbonate ion source is Na 2 CO 3 ) and calcium ions (the source of calcium ions is anhydrous CaCl 2 ) in a 1:1 equal concentration to prepare a salt solution system and place it in a 500mL beaker. After the saline solution system was ultrasonically oscillated for 10 min, the beaker was placed on a magnetic stirrer and magnetically stirred at a speed of 1000 rad / min. At 25°C, when the concentration of carbonate ions and calcium ions is 0.005mol / L and the reaction time is 1h, the salt solution system will generate vaterite-type calcium carbonate; the concentration of carbonate ions and calcium ions is 0.1mol / L, and the reaction temperature When the temperature is 95°C and the reaction time is 1h, the salt solution system will generate aragonitic calcium carbonate; when the reaction temperature is 25°C, the concentration of carbonate ions and calcium ions is 0.6mol / L, and the reaction time is 1h, the salt The solution system will generate calcite type ca...

Embodiment 3

[0044] Carbonate ion (carbonate ion source is Na 2 CO 3 ) and calcium ions (the source of calcium ions is anhydrous CaCl 2) in a 1:1 equal concentration to prepare a salt solution system and place it in a 500mL beaker. After the saline solution system was ultrasonically oscillated for 10 min, the beaker was placed on a magnetic stirrer and magnetically stirred at a speed of 1000 rad / min. At room temperature, when the concentration of carbonate ions and calcium ions is 0.01mol / L and the reaction time is 1h, the salt solution system will generate vaterite-type calcium carbonate; the concentration of carbonate ions and calcium ions is 0.1mol / L, and the reaction temperature is At 80°C and the reaction time is 1h, the salt solution system will generate aragonitic calcium carbonate; when the reaction temperature is 25°C, the concentration of carbonate ions and calcium ions is 0.2mol / L, the reaction time is 3h, the The system produces calcite-type calcium carbonate. The solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com