Liquid fuel and preparation method thereof

A liquid fuel and ionic liquid technology, applied in the chemical field, can solve the problems of large catalyst consumption and long isomerization reaction time, and achieve low cost, small consumption and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 100g bridged tetrahydrotricyclopentadiene raw material in a three-necked round bottom flask, then put the three-necked flask into an oil bath, and after reaching 50°C, add an ionic liquid accounting for 10mol% of bridged tetrahydrotricyclopentadiene (1-Butyl-3-methylimidazolium chloride / AlCl 3 , where AlCl 3 The mole fraction is 0.6), stirring continuously for 3h, standing for 10min after the reaction, and separating the product from the ionic liquid by decantation. The product was characterized by gas chromatographic analysis, and the content of pendant tetrahydrotricyclopentadiene in the product was 95.0 wt%.

Embodiment 2-10

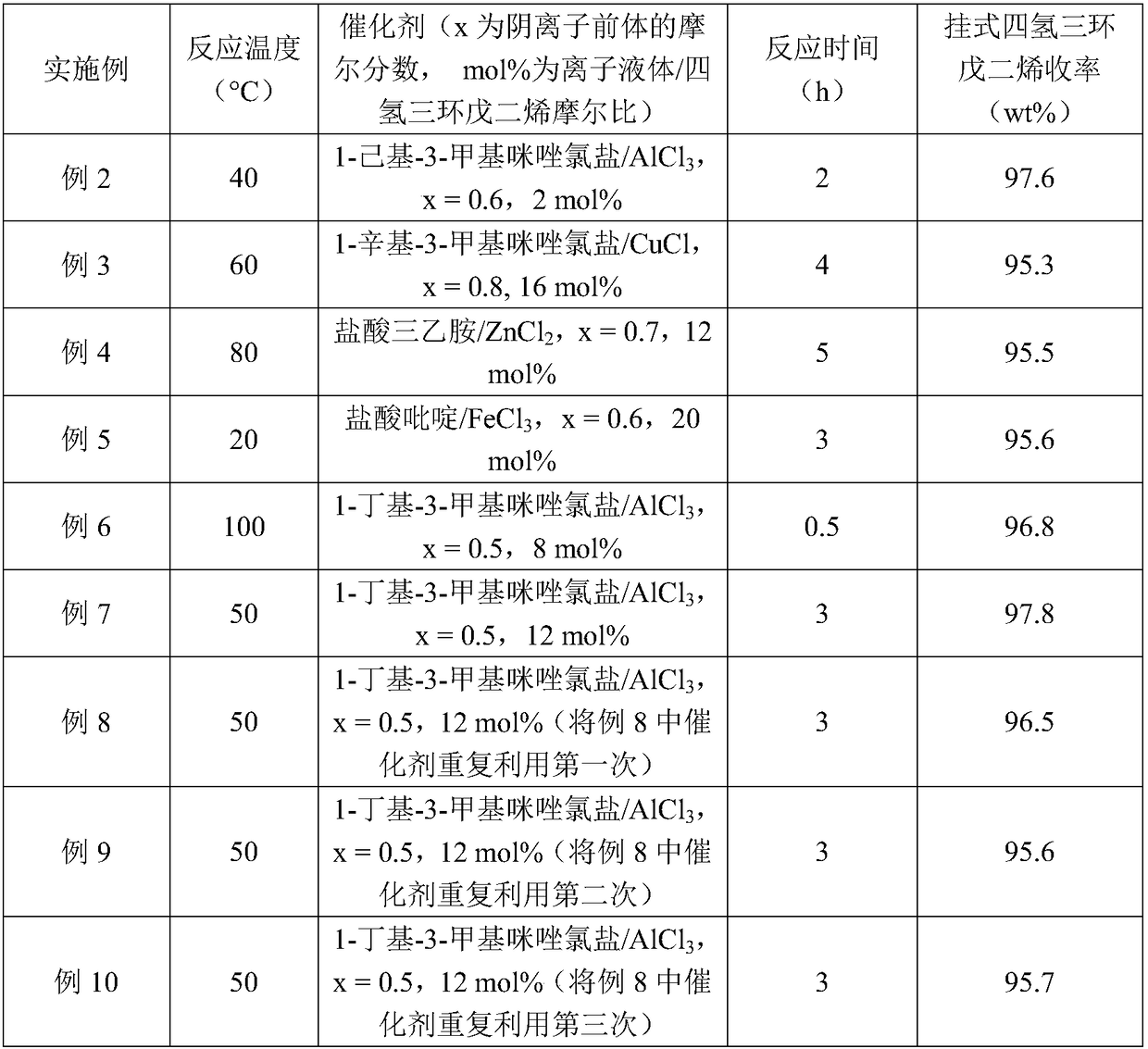

[0020] The reaction process of embodiment 2-10 is the same as embodiment 1, and difference is that adjustment reaction condition comprises: reaction temperature, catalyst (type, proportion, consumption) and reaction time, see the table below. The ionic liquids in Examples 8-10 are used repeatedly.

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com