A process for preparing 2-ethyl-2-hexenal through the self-condensation of n-butyraldehyde catalyzed by an acidic ionic liquid

A technology of acidic ionic liquid and process method, applied in the field of green chemistry, can solve the problems of non-reusable liquid alkali catalyst, poor stability of solid alkali catalyst, high cost of three waste treatment, etc., achieve good industrial application prospects, and overcome the cumbersome post-treatment process , high thermal and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

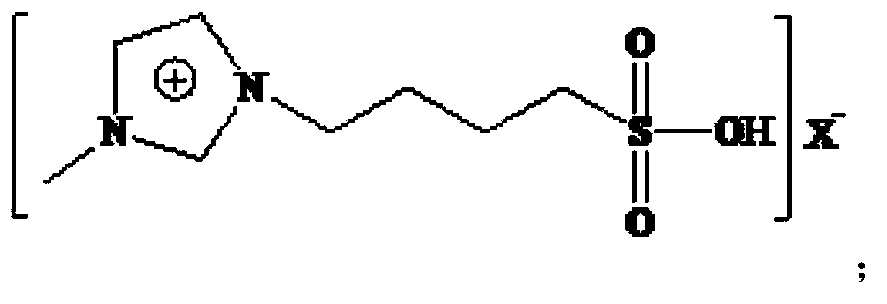

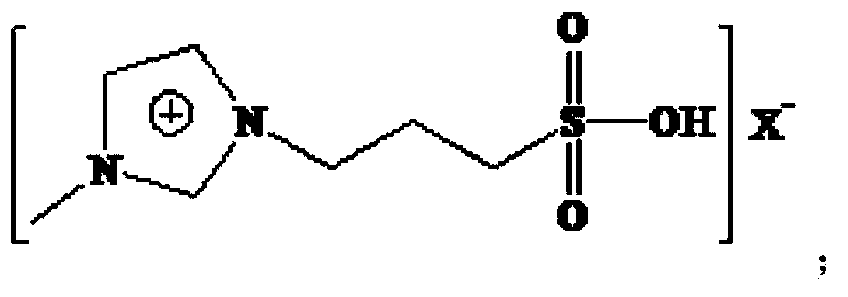

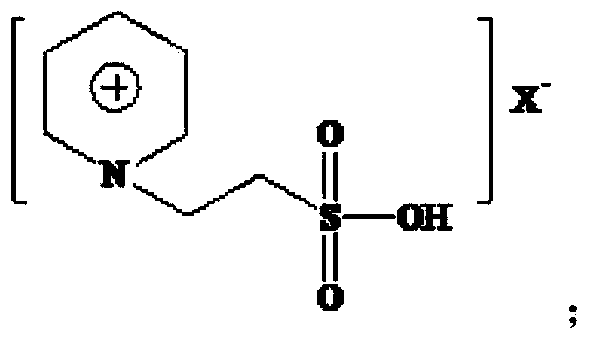

Method used

Image

Examples

preparation example Construction

[0041] other The preparation method of acidic ionic liquid is the same.

[0042] The Lewis acidic ionic liquid involved in the present invention is characterized in that it is a chloroaluminate-based acidic ionic liquid, prepared by the method described by Wikes et al. (Inorg.Chem., 1982, 21:1263). With [Bmim]Cl-AlCl 3 For example:

[0043] (1) Add the purified N-methylimidazole and chlorobutane into a three-necked flask at a molar ratio of 1:1-1:1.5, and react for 24-48 hours at a reaction temperature of 60-80°C , washed and dried to obtain light yellow viscous [Bmim]Cl.

[0044] (2) Under nitrogen protection, [Bmim]Cl was added to the three-necked upper bottle, and AlCl 3 The molar ratio of [Bmim]Cl to [Bmim]Cl is 1:1-3:1 and slowly add anhydrous AlCl in batches 3 , stir evenly, and react at 60-80°C until brown transparent [Bmim]Cl-AlCl is obtained 3 .

[0045] The preparation method of other Lewis acidic ionic liquids is the same.

Embodiment 1

[0047] In a 100ml autoclave, put 40g of n-butyraldehyde, and then add [Bmim]Cl-ZnCl with 1% n-butyraldehyde weight 2 ionic liquid, with N 2 Air replacement, magnetic stirring, and reaction at 150°C for 5 hours. After the reaction, the reaction solution was left to stand. After the reaction solution was separated, the upper layer liquid was taken for gas chromatography analysis. The conversion rate of n-butyraldehyde was 72.7%, and 2-ethyl The selectivity of -2-hexenal is 59.5%.

[0048] Examples 2-80 were carried out according to the operation steps of Example 1, and the reaction conditions and results are shown in the summary table.

[0049]

[0050]

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com