A kind of sulfuric acid catalytic composite and its application in the production of alkylated gasoline

A compound and sulfuric acid technology, which is applied in the production of liquid hydrocarbon mixtures, catalytic reactions, chemical/physical processes, etc., can solve the problems of high price and complex molecular structure, and achieve the advantages of low price, low equipment corrosion, and reduced acid consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

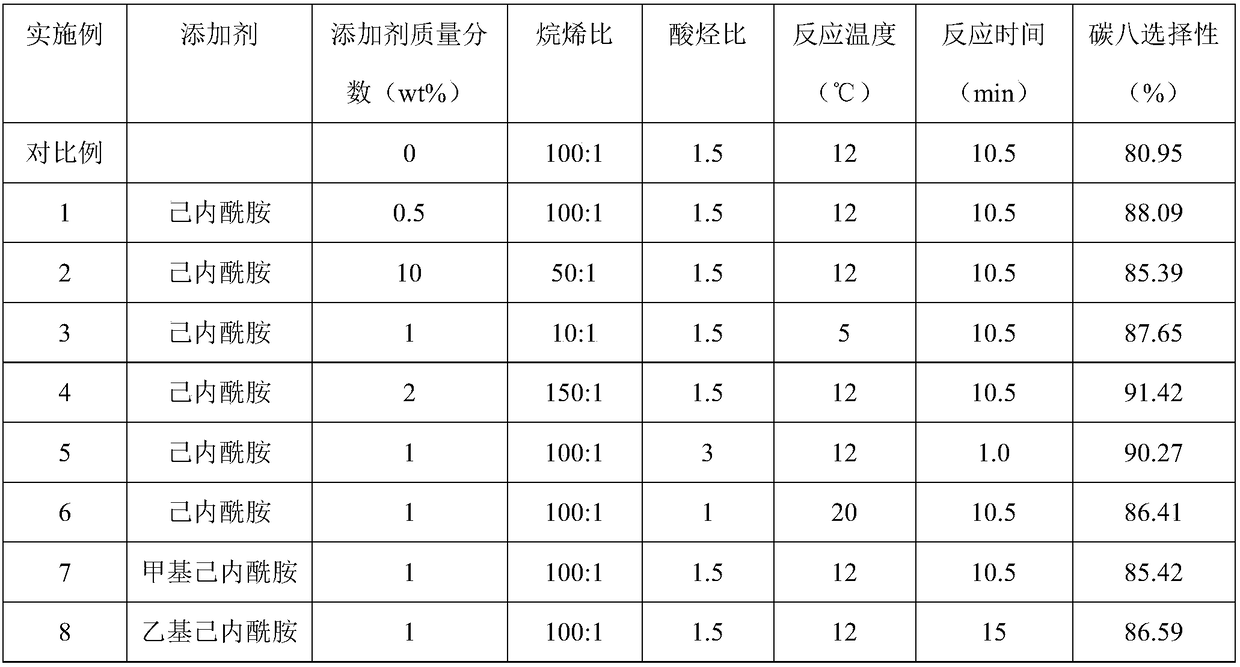

Embodiment 1

[0017] First, add 150mL of sulfuric acid containing 0.5wt% caprolactam into the stainless steel stirred tank through a pump, feed nitrogen to evacuate, and control the pressure of the reactor at 0.3MPa, start stirring, and the speed is 1000r / min. When the temperature of the reactor was 12°C, 100 mL of a mixture of isobutane and butene (1-butene, 2-butene or isobutene) with an alkene ratio of 100:1 was added via a pump. After reacting for 10.5 minutes, stop stirring, open the vent valve, turn on the stirring tank, add a certain amount of extractant, take samples, and analyze the content of each component in the product by chromatography.

Embodiment 2

[0019] First, add 150mL of sulfuric acid containing 10.0wt% caprolactam into the stainless steel stirred tank through a pump, pass through nitrogen to evacuate, and control the pressure of 0.3MPa in the reactor, start stirring, and the speed is 1000r / min. When the temperature of the reaction kettle was 12°C, 100 mL of a mixture of isobutane and butene with an alkene ratio of 50:1 was added through a pump. After reacting for 10.5 minutes, stop stirring, open the vent valve, turn on the stirring tank, add a certain amount of extractant, take samples, and analyze the content of each component in the product by chromatography.

Embodiment 3

[0021] First, add 150mL of sulfuric acid containing 1.0wt% caprolactam into the stainless steel stirred tank through a pump, pass through nitrogen to evacuate, and control the pressure of 0.3MPa in the reactor, start stirring, and the speed is 1000r / min. When the temperature of the reaction kettle was 5°C, 100 mL of a mixture of isobutane and butene with an alkene ratio of 10:1 was added via a pump. After reacting for 10.5 minutes, stop stirring, open the vent valve, turn on the stirring tank, add a certain amount of extractant, take samples, and analyze the content of each component in the product by chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com