Waste heat recovery type air treatment unit

An air handling unit and waste heat recovery technology, which is applied in the fields of construction and environmental protection, can solve the problems of ventilation, cross-contamination of exhaust air, low heat recovery efficiency, and large wind side flow resistance, and achieve small installation height requirements and high heat transfer efficiency , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

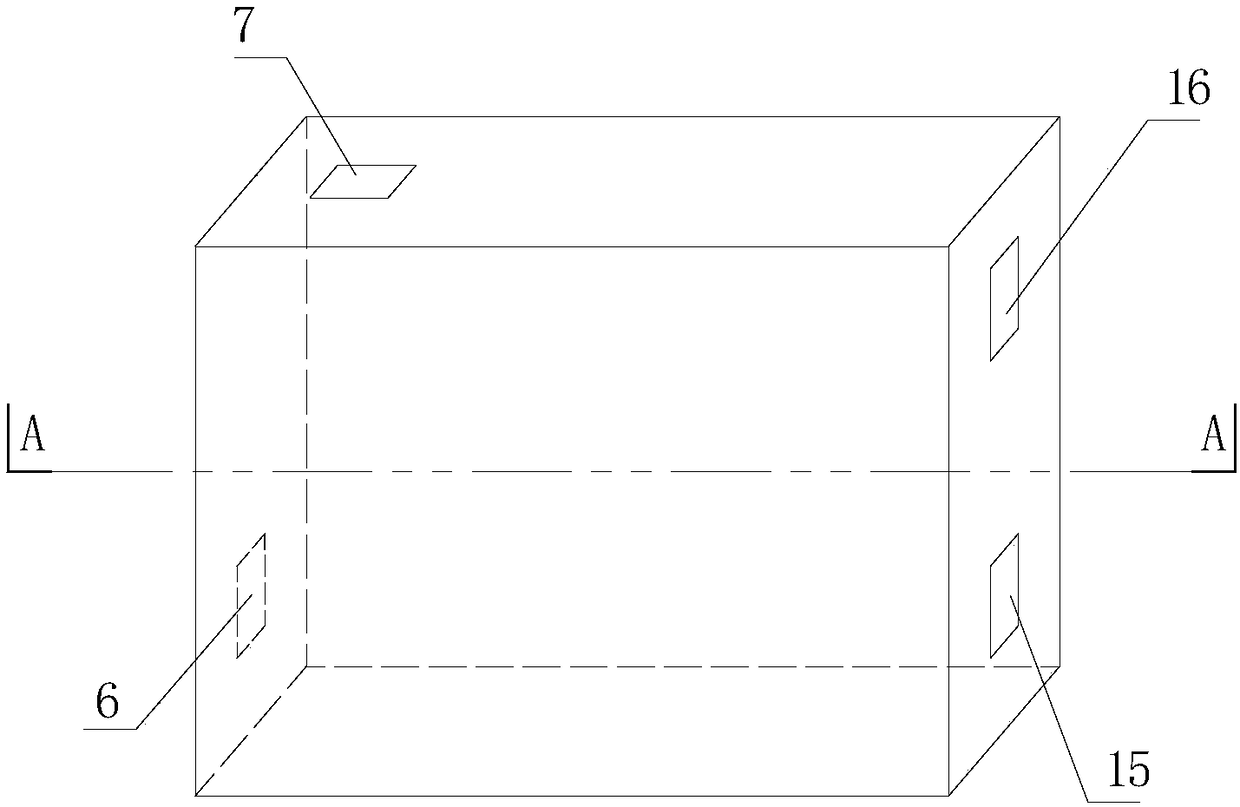

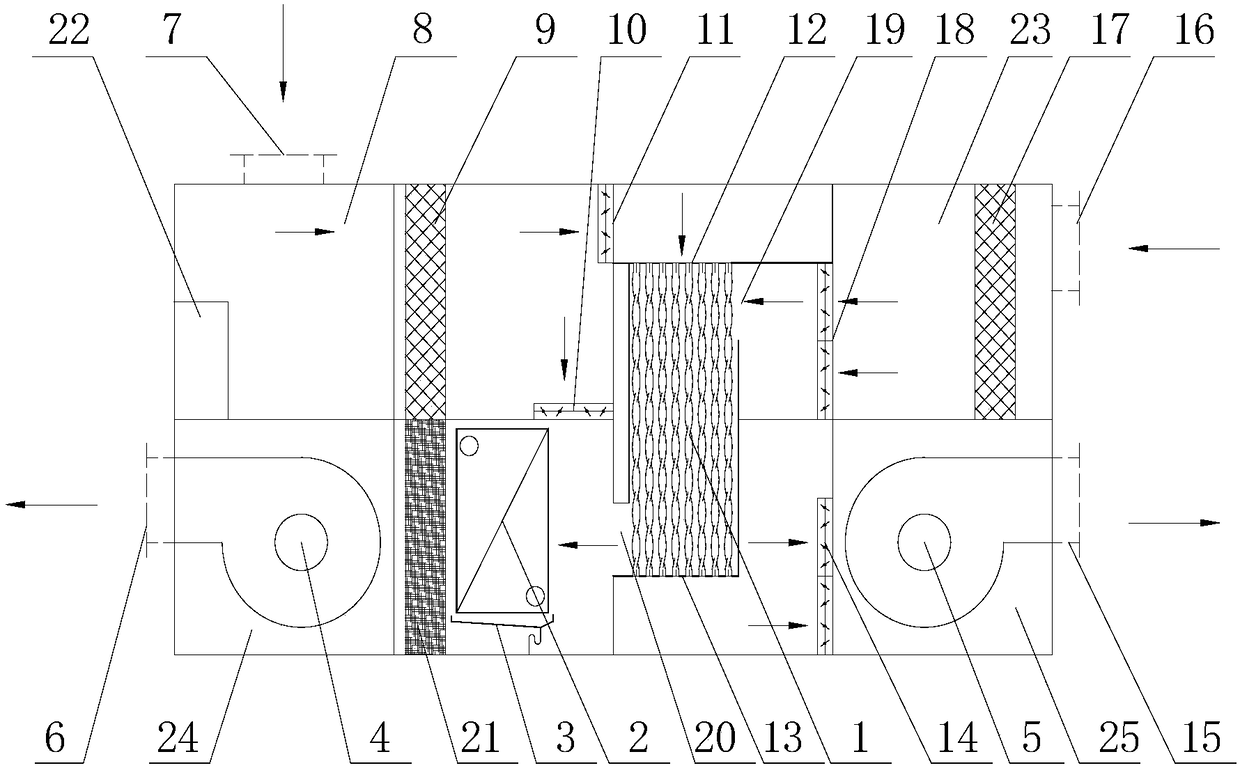

[0032] Such as figure 1 and figure 2 As shown, a waste heat recovery type air handling unit is a box structure, the upper left part of the box is the return air chamber 8, the upper right part is the fresh air chamber 23, the lower left part is the air supply chamber 24, and the lower right part is the exhaust chamber 25. The middle part is a three-dimensional variable structure high-efficiency heat recovery device 1.

[0033] The top surface of the air return chamber 8 is provided with a return air outlet 7, the bottom surface communicates with the air supply chamber 24 through the first air return valve 10, and the right side passes through the second air return valve 11, the return air inlet 12 and the three-dimensional variable structure for efficient heat recovery. The return air channel of the device 1 is connected, and a return air coarse filter 9 is arranged in the flow channel between the return air port 7 and the first return air valve 10 and the second return air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com