Internal combustion engine intercooler circulating water waste heat recovering device and method

A technology of waste heat recovery device and internal combustion engine, applied in heat recovery system, machine operation mode, machine using waste heat, etc., can solve the problems of low boiler thermal efficiency, complicated operation management system design, etc., achieve high safety and reliability, save engineering cost, and the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

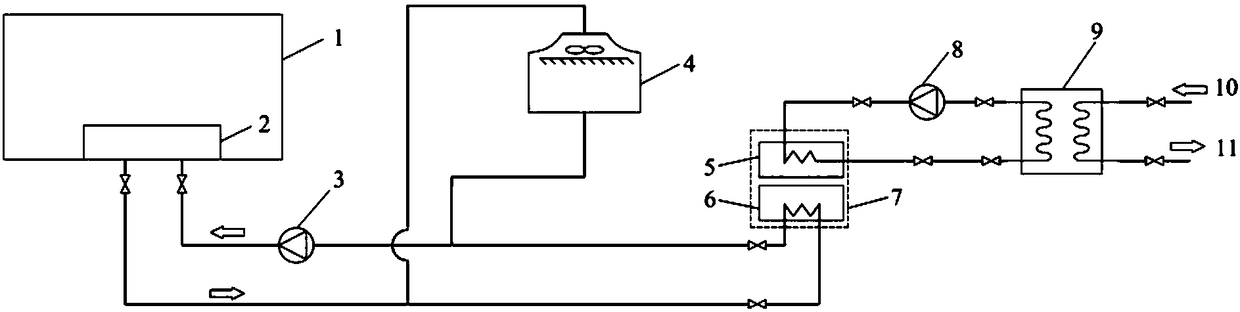

[0034] Hereinafter, the preferred embodiments of the present invention will be introduced with reference to the drawings in the specification, so that the technical content will be clearer and easier to understand. The present invention can be embodied by many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned in the text.

[0035] In a preferred embodiment of the present invention, an internal combustion engine intercooler circulating water waste heat recovery device includes a cooling tower system and a high temperature water source heat pump system connected to the internal combustion engine intercooler, and the cooling tower system and the high temperature water source heat pump system operate in parallel and mutually It is reserved for cooling the circulating water of the intercooler of the internal combustion engine.

[0036] Such as figure 1 As shown, in the circulating water cooling system of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com