Method for testing residual stress of thick plate by neutron diffraction technology

A technology of residual stress and neutron, which is applied in the field of testing the residual stress of thick plates using neutron diffraction technology, can solve the problems of increasing the standard volume and testing time, and increasing the testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

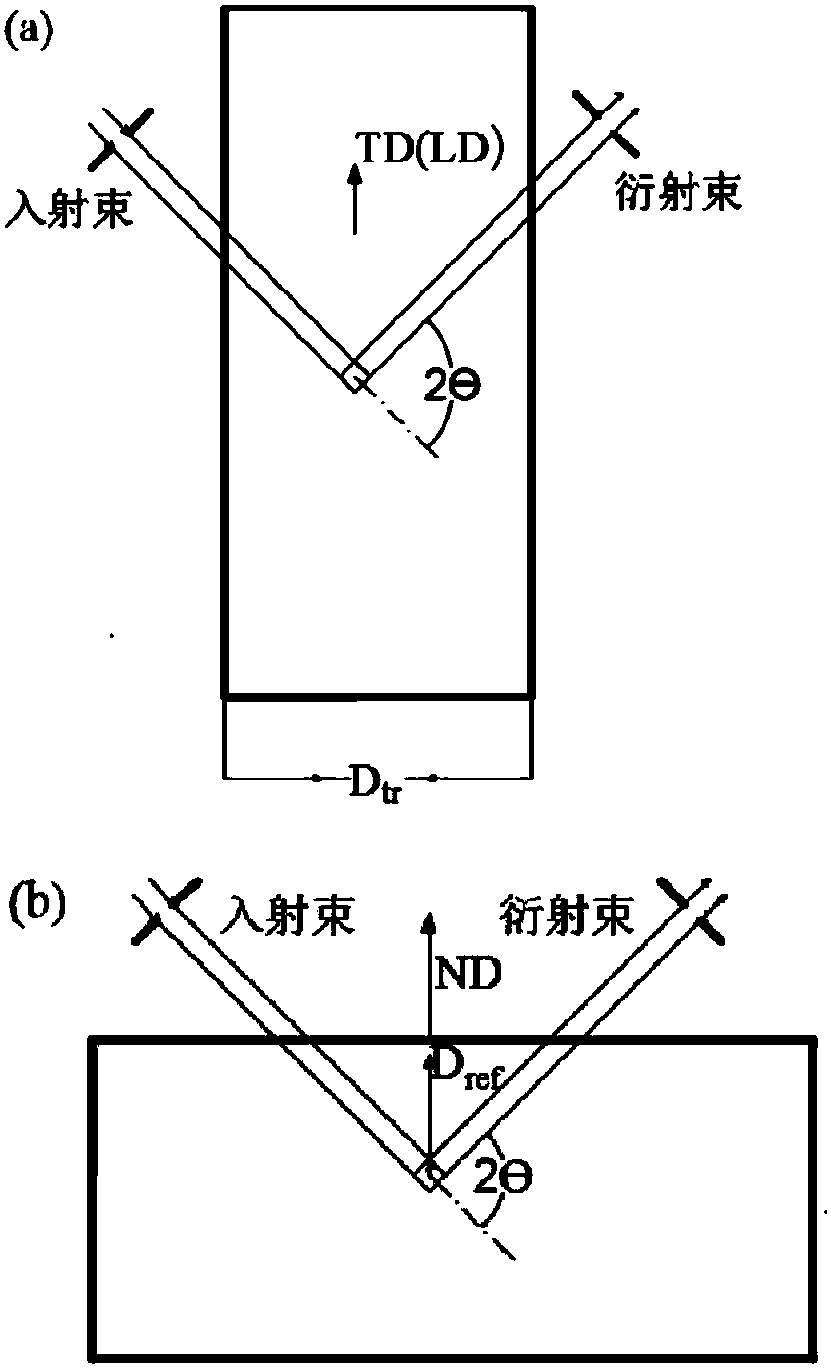

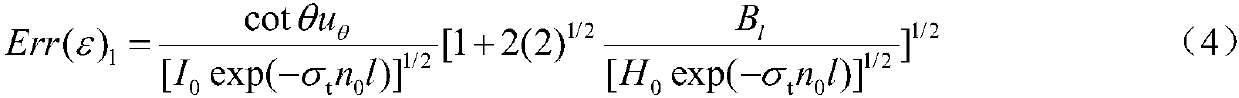

[0065] In general, increasing the gauge volume and test time is a common method for testing the residual stress of thick plates using neutron diffraction. In the transmission mode, the total neutron penetration path length along the thickness direction has nothing to do with the location of the test point; in the reflection mode, the neutron penetration path length increases with the increase of the depth of the test point. Internal test points require larger gauge volumes or longer test times than surface test points to ensure sufficient signal counts for residual stress analysis. However, the maximum size of the specification volume is limited by the resolution required by the test, and the test time cannot be effectively increased due to the limitation of the opening time. Moreover, the neutron intensity decays exponentially with the length of the neutron penetration path. Increasing the standard volume and test time has very limited effects, and cannot greatly increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com