Detection method of syringic acid

A detection method and technology of syringic acid, applied in the field of analysis and detection, can solve the problems of complicated operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

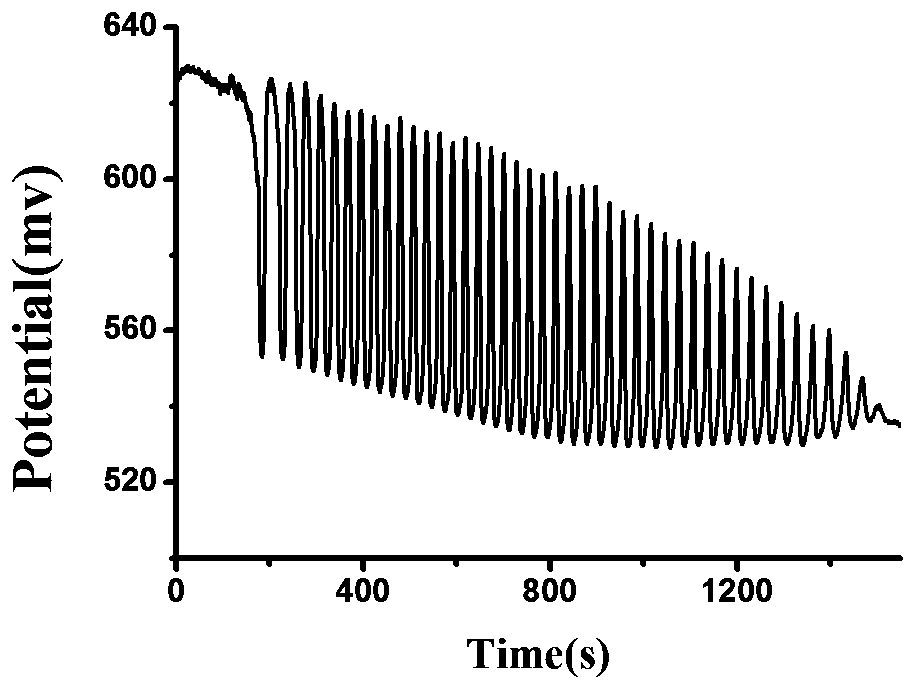

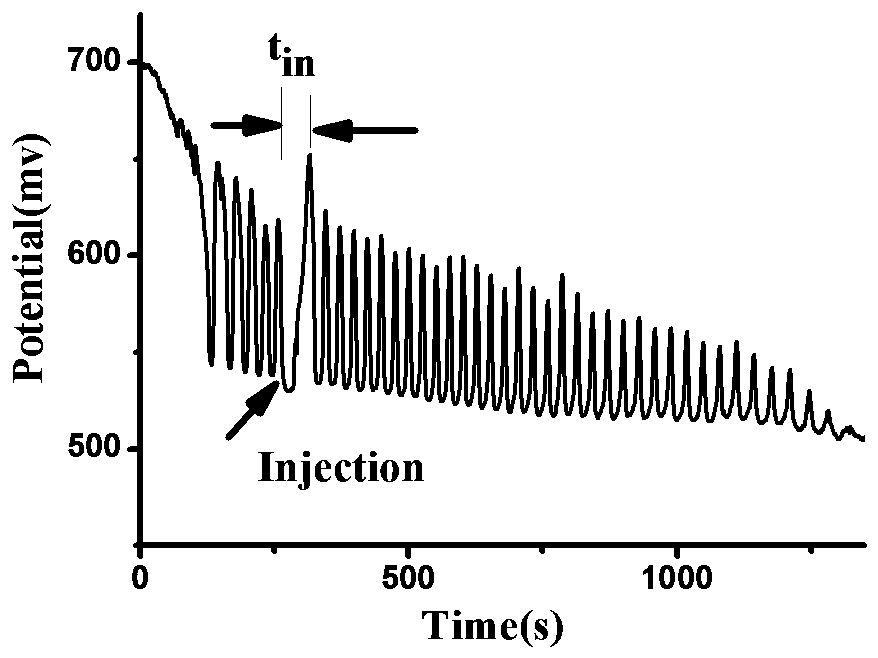

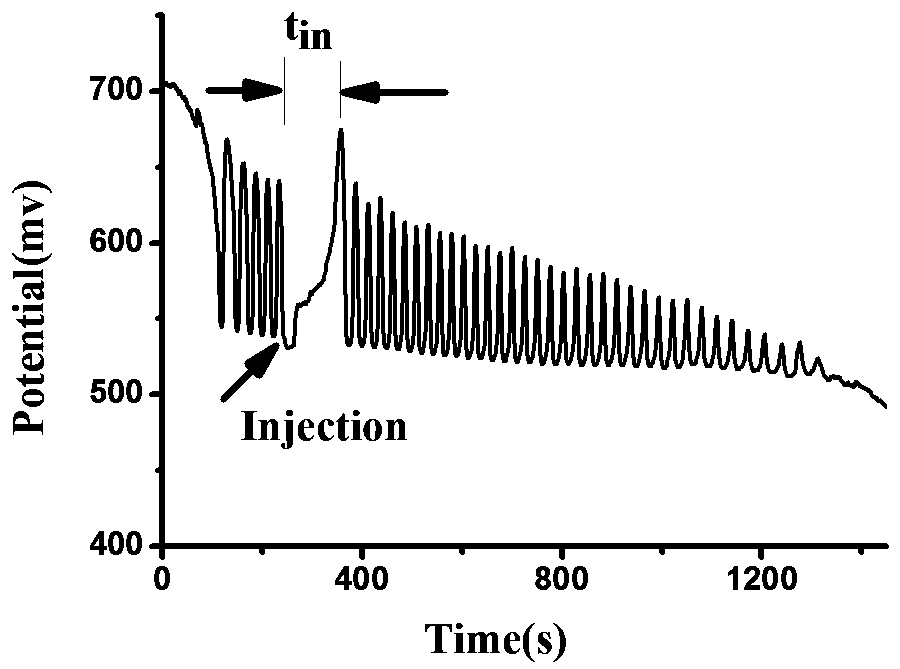

[0053] App H 2 SO 4 - KIO 3 - [NiL](ClO 4 ) 2 - MA (malonate)-H 2 o 2 The Briggs-Rauscher oscillation system was used as the detection solution for quantitative analysis of syringic acid. Add different concentrations of syringic acid sample solutions into the shaking system, and establish a working curve (such as a linear relationship graph) between the concentration of the analyte and the inhibition time, so as to achieve the purpose of detecting the content of syringic acid in the sample.

[0054] (1) Prepare H 2 SO 4 - KIO 3 - [NiL](ClO 4 ) 2 - MA (malonate)-H 2 o 2 detection solution

[0055] First prepare the sulfuric acid solution of 0.025mol / L with 98% concentrated sulfuric acid as a solvent; then use the sulfuric acid solvent of 0.025mol / L to prepare respectively the potassium iodate solution of 0.14mol / L, the malonic acid solution of 2.0mol / L, and the 4.0 mol / L hydrogen peroxide solution and 0.0173mol / L [NiL](ClO 4 ) 2 solution. Then, add 14.7ml...

Embodiment 2

[0062] (1) Prepare H 2 SO 4 - KIO 3 - [NiL](ClO 4 ) 2 - MA (malonate)-H 2 o 2 detection solution

[0063] First prepare the sulfuric acid solution of 0.025mol / L with 98% concentrated sulfuric acid as a solvent; then use the sulfuric acid solvent of 0.025mol / L to prepare respectively the potassium iodate solution of 0.14mol / L, the malonic acid solution of 2.0mol / L, and the 4.0 mol / L hydrogen peroxide solution and 0.0173mol / L [NiL](ClO 4 ) 2 solution. Then, add 14ml, 0.025mol / L sulfuric acid solution successively to the open system of 50ml beaker; 0.5ml distilled water; 6.5ml, the potassium iodate solution of 0.14mol / L; 2.0mol / L malonic acid solution; 14.5ml, 4.0mol / L hydrogen peroxide solution. Finally, the concentration of sulfuric acid in the system is 0.0246875mol / L, the concentration of potassium iodate is 0.02275mol / L, and the concentration of catalyst is 6.4875×10 -4 mol / L, the concentration of malonic acid is 0.15mol / L, and the concentration of hydrogen per...

Embodiment 3

[0070] 1) Prepare H 2 SO 4 - KIO 3 - [NiL](ClO 4 ) 2 - MA (malonate)-H 2 o 2 detection solution

[0071] First prepare the sulfuric acid solution of 0.025mol / L with 98% concentrated sulfuric acid as a solvent; then use the sulfuric acid solvent of 0.025mol / L to prepare respectively the potassium iodate solution of 0.14mol / L, the malonic acid solution of 2.0mol / L, and the 4.0 mol / L hydrogen peroxide solution and 0.0173mol / L [NiL](ClO 4 ) 2 solution. Then, add 14.5ml, 0.025mol / L sulfuric acid solution to the open system of 50ml beaker; 6ml, 0.14mol / L potassium iodate solution; 2ml, 0.0173mol / L catalyst; 3ml, 2.0mol / L Malonic acid solution; 14.5ml, 4.0mol / L hydrogen peroxide solution. Finally, the concentration of sulfuric acid in the system is 0.025mol / L, the concentration of potassium iodate is 0.021mol / L, and the concentration of catalyst is 8.65×10 -4 mol / L, the concentration of malonic acid is 0.15mol / L, and the concentration of hydrogen peroxide is 1.45mol / L. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com