Etchant composition

A technology of etching solution and composition, applied in the field of etching solution composition for silver or silver alloy, can solve the problems of large variation of pattern, harsh working environment, uneven size of silver or silver alloy pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The commercially available 85% (weight %) phosphoric acid aqueous solution (specific gravity 1.69) of 64 volume parts is mixed with the commercially available 70% (weight %) nitric acid aqueous solution (specific gravity 1.42) of 0.5 volume part, then this mixture is mixed with 5 volume parts 35 An aqueous solution of maleic acid (specific gravity: 1.12) was mixed to obtain an etching solution. In addition, a substrate having a silver film (silver 100%) having a film thickness of 0.2 μm on a glass substrate was prepared. This substrate was immersed in the above etching solution, and the time required for the thin film to disappear at 35° C. was measured to calculate the etching rate. The results are shown in Table 1.

Embodiment 2~4

[0028] The amount of the aqueous solution of maleic acid used was 10 parts by volume in Example 2, 15 parts by volume in Example 3, and 20 parts by volume in Example 4. In addition, the etching rate was obtained in the same manner as in Example 1. The results are listed together in Table 1.

[0029]

[0030] Any of the etching solutions in Examples 1 to 4 can etch silver. Example 4 is an etching solution containing more maleic acid, and a little maleic acid can be seen to be precipitated, and the etching rate is reduced to some extent.

Embodiment 5

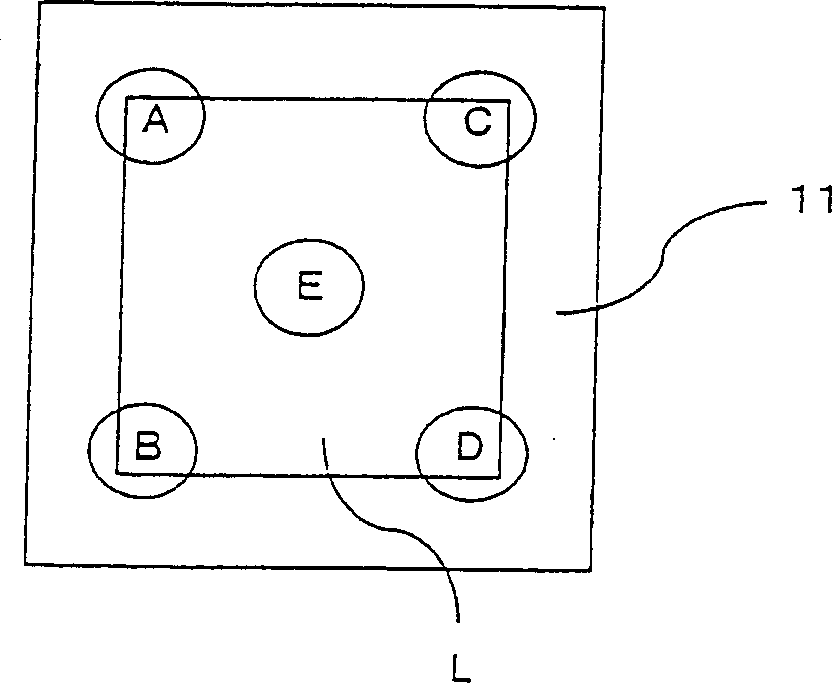

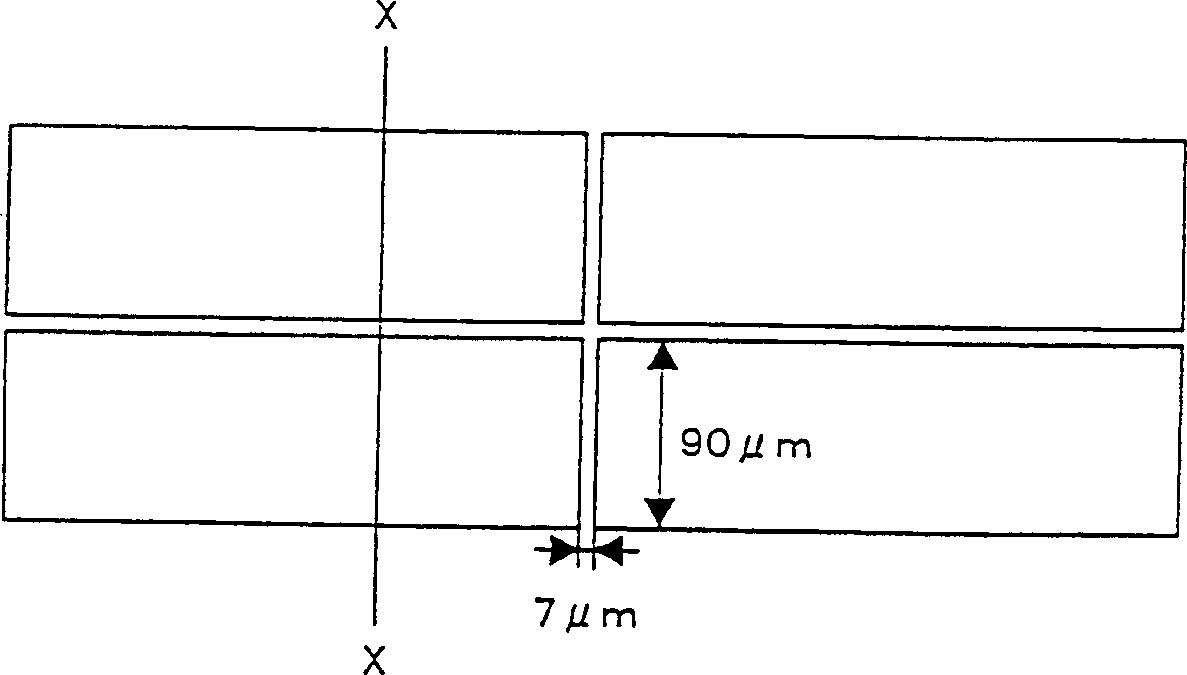

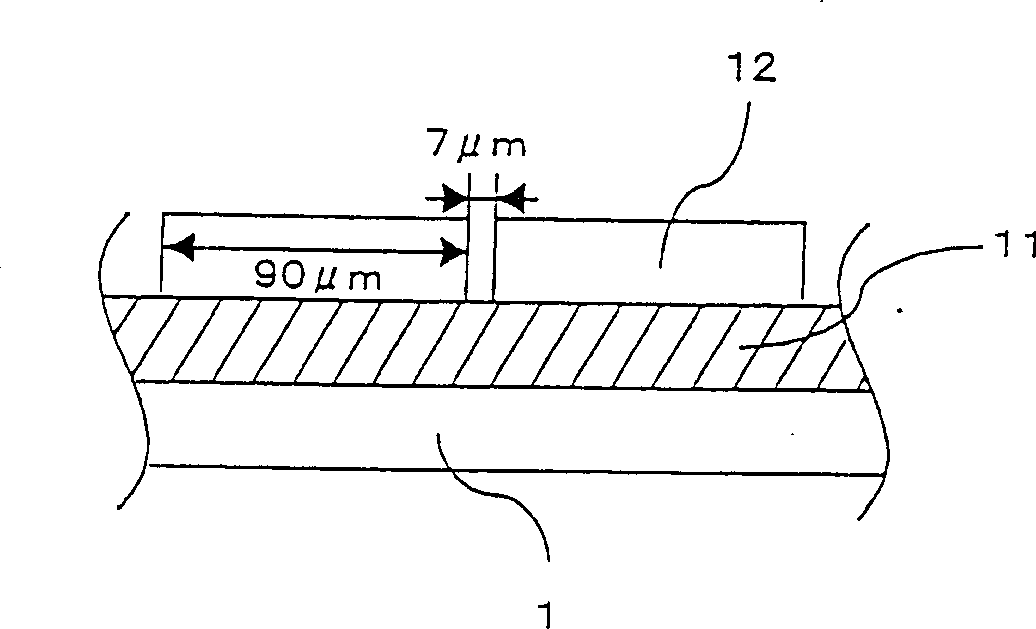

[0032] An etching solution containing 48.5% by weight of phosphoric acid, 11.5% by weight of nitric acid, 1% by weight of oxalic acid, and 39% by weight of water was prepared. In addition, a glass substrate (10 cm×10 cm) having a silver film with a film thickness of 0.2 μm on the surface was prepared. A protective film (thermoplastic phenolic resin) film is formed on the silver film of this substrate, and a striped pattern is formed by exposure and development. Such as figure 1 As shown, the protective film of the striped pattern is formed in the 9cm×9cm area of the central part of the substrate ( figure 1 on the silver film 11 in the area shown in L). Such as figure 2 As shown, the striped pattern is a rectangular pattern with a short side of 90 μm and a long side of 300 μm, and each pattern is formed on the surface of the silver film at a distance of 7 μm in length and width. image 3 for along figure 2 A schematic cross-sectional view of line X-X of FIG. 1 shows th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com