Method for light weight of 3D printing personalized external fixed supporting tool based on topology optimization

A topology optimization and 3D printing technology, applied in 3D modeling, design optimization/simulation, image data processing, etc., can solve the problems of difficult strength characteristics, poor air permeability and wearing comfort, low degree of automation, etc., and meet the requirements of hardware equipment Low, ensure stiffness and strength, overcome time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

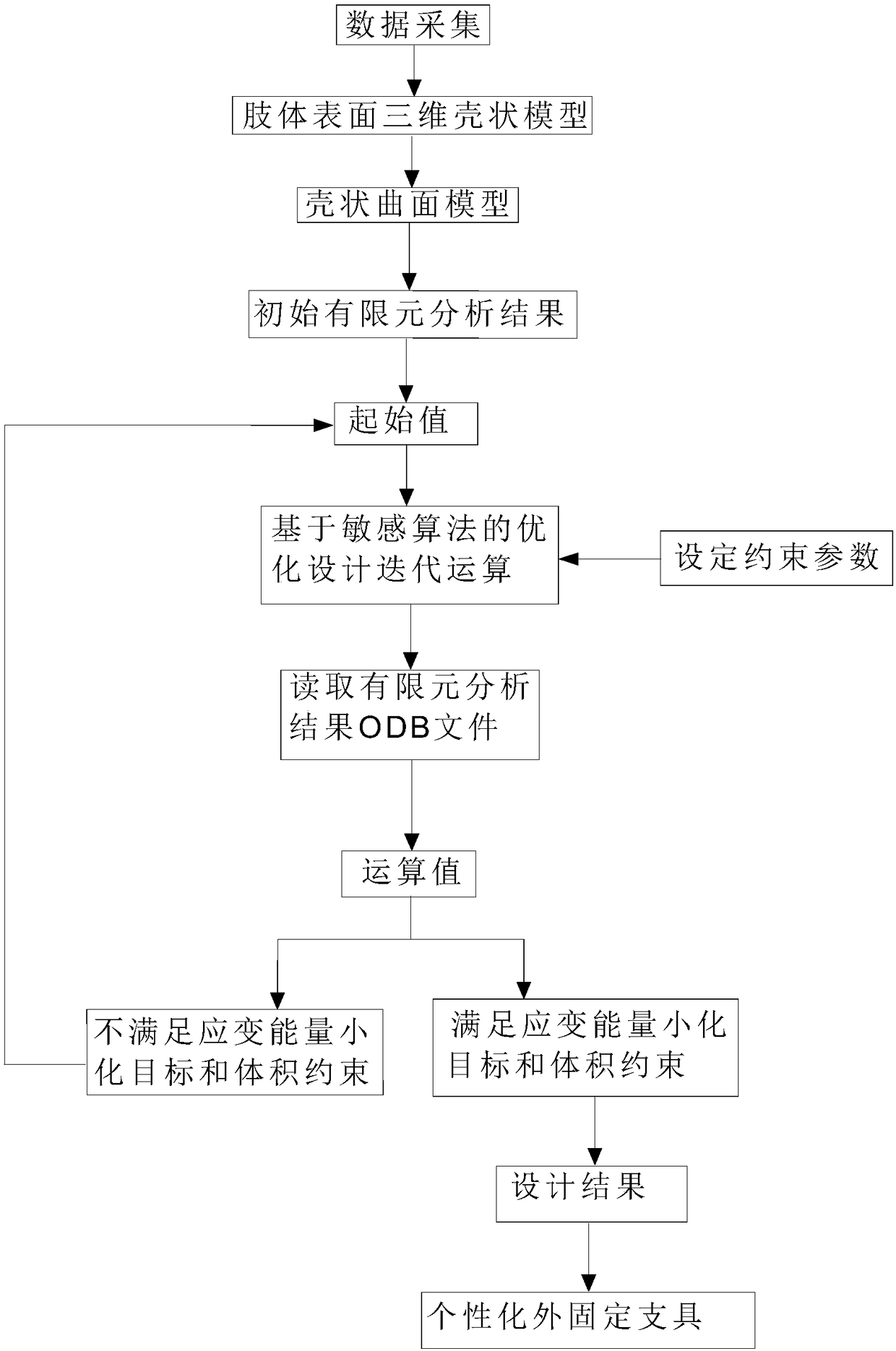

[0055] The lightweight method of 3D printing personalized external fixation brace based on topology optimization, such as figure 1 shown, including the following steps:

[0056] Step 1, scan the body of the subject to obtain data;

[0057] Step 2, import the data obtained in step 1 into the software, perform image segmentation and three-dimensional construction of the model to obtain a three-dimensional shell model of the limb surface;

[0058] In step 3, the three-dimensional shell-shaped model of the limb surface obtained in step 2 is subjected to model surface modification processing, and a curved surface sheet of the outer contour of the limb is constructed, and imported into computer-aided design software to convert it into a shell-shaped curved surface model;

[0059] Step 4, import the above-mentioned three-shell surface model into the finite element analysis software, define limited parameters, perform grid division of the brace model, submit it to the finite element ...

Embodiment 2

[0091] Based on the lightweight method of 3D printing personalized external fixation brace based on topology optimization, the present invention is described with a specific clinically common personalized design of external fixation brace after Achilles tendon injury repair, and the specific implementation steps are as follows:

[0092] Step 1, limb surface contour data acquisition and 3D reconstruction:

[0093]The data of the affected lower limb of the subject is collected by computerized tomography (CT) equipment, and the scanned data must completely cover the range of limbs to be fixed by the external fixation brace.

[0094] Step two, 3D reconstruction:

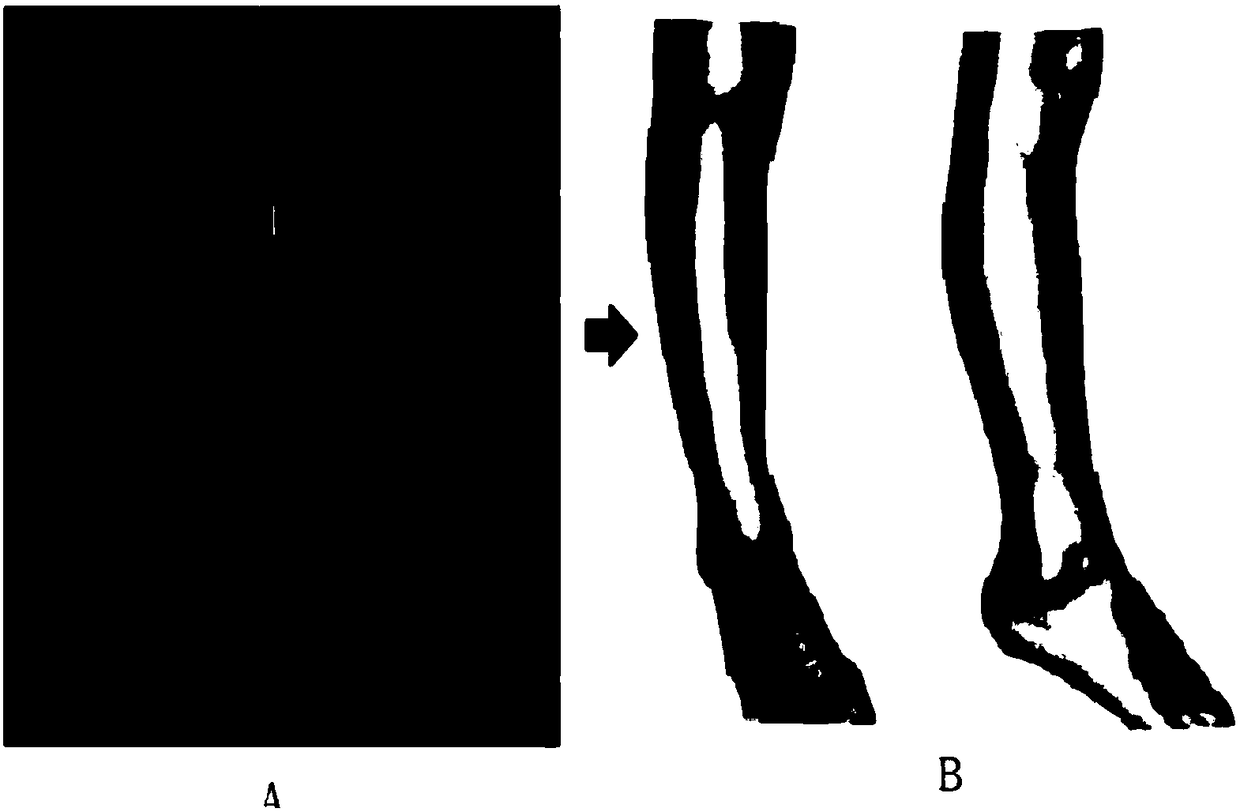

[0095] The obtained tomographic images are imported into 3D reconstruction software in DICOM data format for image segmentation processing, such as figure 2 As shown in , a three-dimensional model of the outer contour of the limb on the injured side of the Achilles tendon was established.

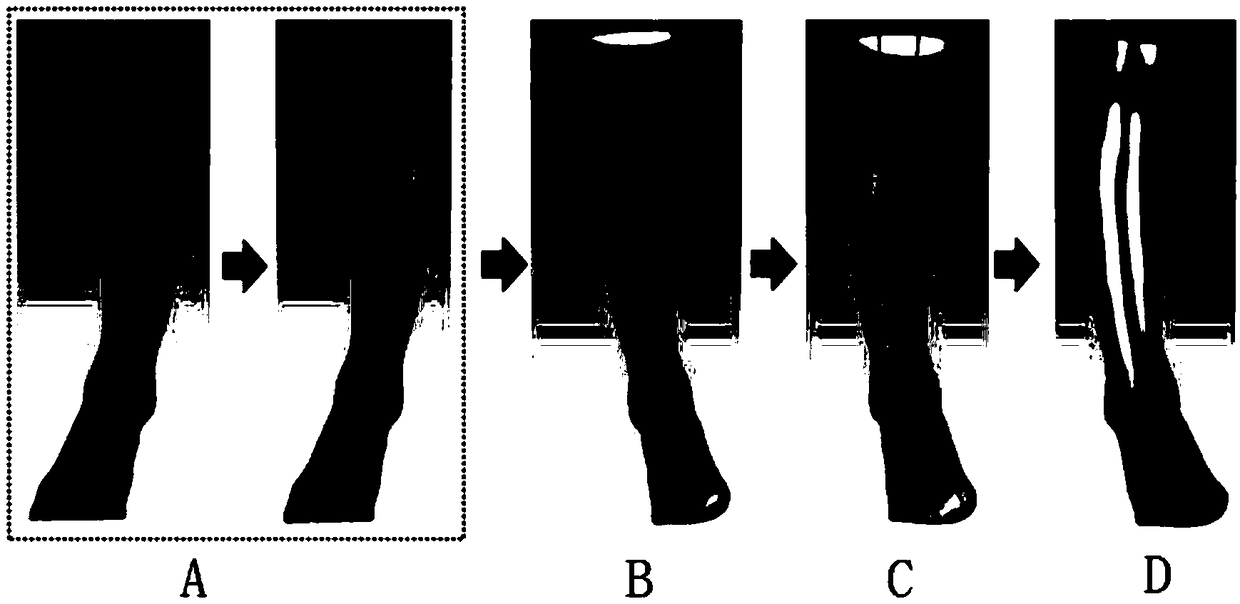

[0096] Step 3, surface trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com