Self-adaptive regulating heat dissipation device capable of intelligently responding to hot spots of chip

A technology of self-adaptive regulation and heat dissipation device, applied in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problem of poor chip cooling effect, achieve low flow pressure drop, realize micro-scale heat dissipation, and system economy simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

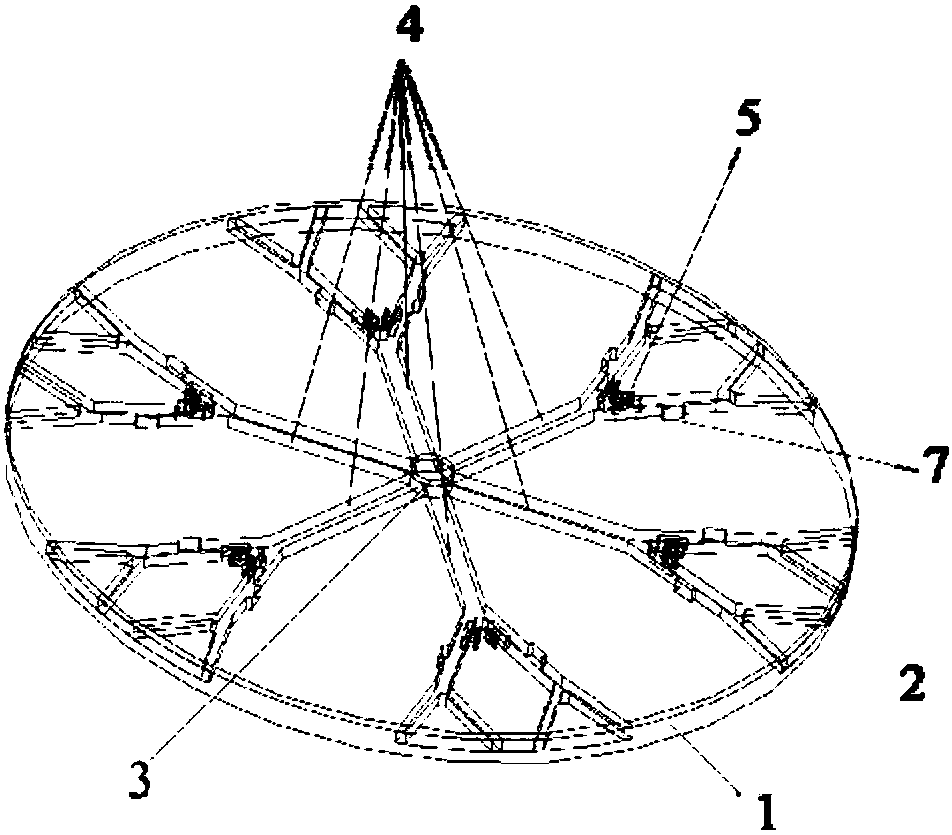

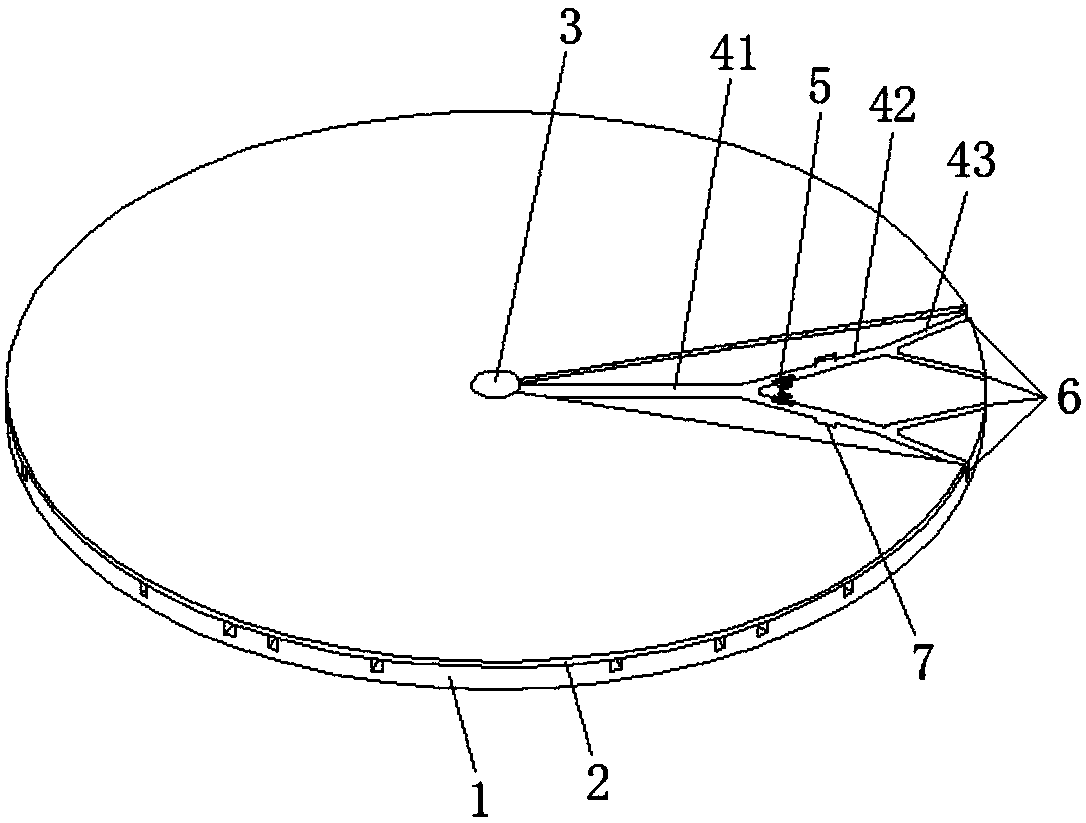

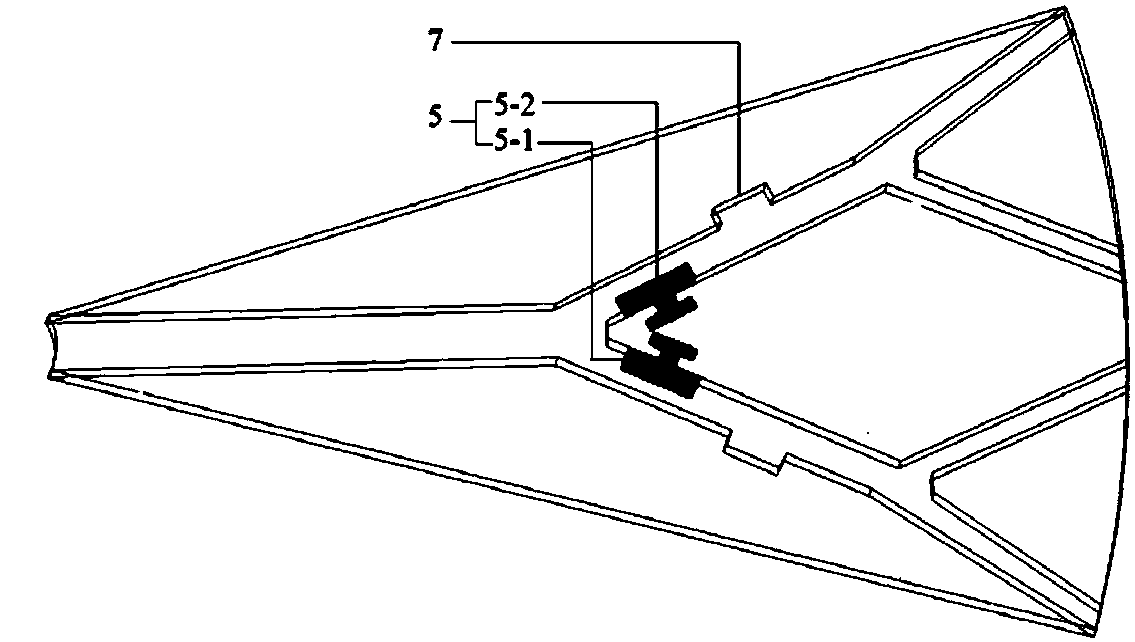

[0027] Such as figure 1 , 2As shown, an adaptive heat dissipation device for intelligently responding to chip hotspots includes a heat sink substrate 1 and an upper cover plate 2 , the upper cover plate 2 covers the heat sink substrate 1 and is sealed with the heat sink substrate 1 . The area and material of the upper cover plate 2 and the radiator substrate 1 are the same, and the upper cover plate 2 and the radiator substrate 1 are glued together by silica gel, and a pre-tightening force can also be applied to improve the sealing performance. A through hole 3 serving as a fluid inlet is etched in the center of the upper cover plate 2 . A central fluid inlet corresponding to the through hole 3 of the upper cover plate 2 and having the same radius is etched on the radiator substrate 1, and a plurality of fractal microchannels 4 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com