Thermosetting resin composition for sealing, and sheet for sealing

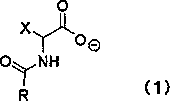

A resin composition and thermosetting technology, applied in the fields of electric solid device, climate sustainability, semiconductor/solid device manufacturing, etc., can solve the problems of increasing resistance, brightness reduction, peeling, etc., and achieve the effect of prolonging the life of components and inhibiting deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0137] Hereafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. In the following description, unless otherwise specified, "%" and "part" other than the reaction rate and thermal weight loss rate of the cured product represent "mass%" and "mass part", respectively. As the hydrotalcites, all commercially available hydrotalcites whose saturated water absorption rate, thermal weight loss rate, and X-ray diffraction peak were measured were used.

[0138]

[0139] The following steps were used to synthesize N-acetylglycine tetrabutylphosphonium salt as an ionic liquid curing agent. To 20.0 g of a 41.4% tetrabutylphosphonium hydroxide aqueous solution (manufactured by Hokko Chemical Industry Co., Ltd.), 3.54 g of N-acetylglycine (manufactured by Tokyo Chemical Industry Co., Ltd.) was added at 0° C., and stirred for 10 minutes . Using an evaporator, the reaction solution was concentrated at 60 to 80° C. for 2 hours at ...

Embodiment 2

[0144] Instead of hydrotalcite A (22 parts), hydrotalcite B (BET specific surface area 15m 2 / g, 15 parts), except that, it was carried out similarly to Example 1, the thermosetting resin composition varnish was manufactured, and the sheet|seat for sealing was obtained.

Embodiment 3

[0146] Instead of hydrotalcite A (22 parts), hydrotalcite A (14 parts) and hydrotalcite C (BET specific surface area 146m 2 / g, 5 parts) mixed hydrotalcite (BET specific surface area 48m 2 / g) except that, it carried out similarly to Example 1, the thermosetting resin composition varnish was manufactured, and the sheet|seat for sealing was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com