Mold cooling pipe wall limescale peeling device

A mold cooling and stripping device technology, which is applied in the direction of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of low efficiency, incomplete cleaning, and high local temperature of molds, so as to improve cleaning quality and avoid cleaning Difficulty, effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

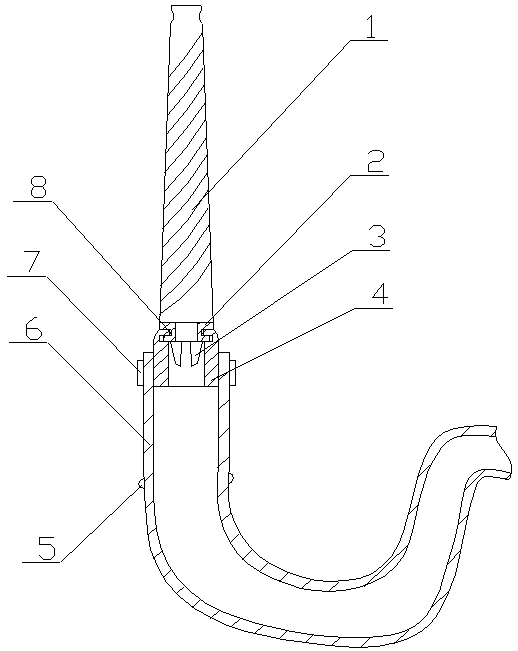

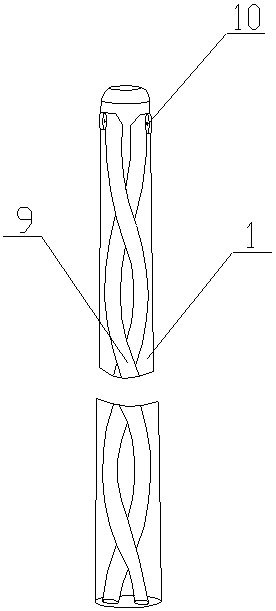

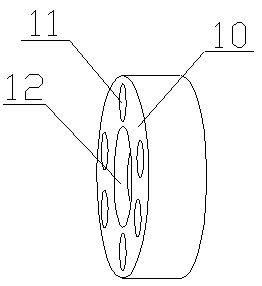

[0023] A mold cooling pipe wall scale stripping device of the present invention is realized in this way. When in use, the other end of the communication hose (6) is connected with the fluid medium, and the fluid medium is any one of high-pressure water, high-pressure air, and cleaning liquid. Mix one or more kinds, then extend the small end of the stripping tube (1) from the mouth of the mold cooling tube, and then open the fluid medium so that the fluid enters along the connecting hose (6) and impacts the ferrule (2) The rotating blade (3) at the bottom drives the rotating blade (3) to rotate, and then drives the ferrule (2) to rotate, and drives the stripping tube (1) to rotate through the ferrule (2). When the stripping tube (1) rotates, The spiral groove on the surface is attached to the wall of the cooling pipe for rotational grinding. At the same time, through the screwing of the spiral groove, the connecting hose (6) is gradually pulled to the depth along the cooling pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com